Plastic DBM (decalcified bone matrix) bone induced self-curing bone grafting material and preparation method thereof

An osteoinductive and self-curing technology, which is applied in the fields of pharmaceutical formulation, medical science, tissue regeneration, etc., can solve the problems of mechanical properties and degradation performance, lack of mechanical support, and self-curing, etc., to achieve rapid bone formation and widen the raw material source, the effect of good anti-collapse performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

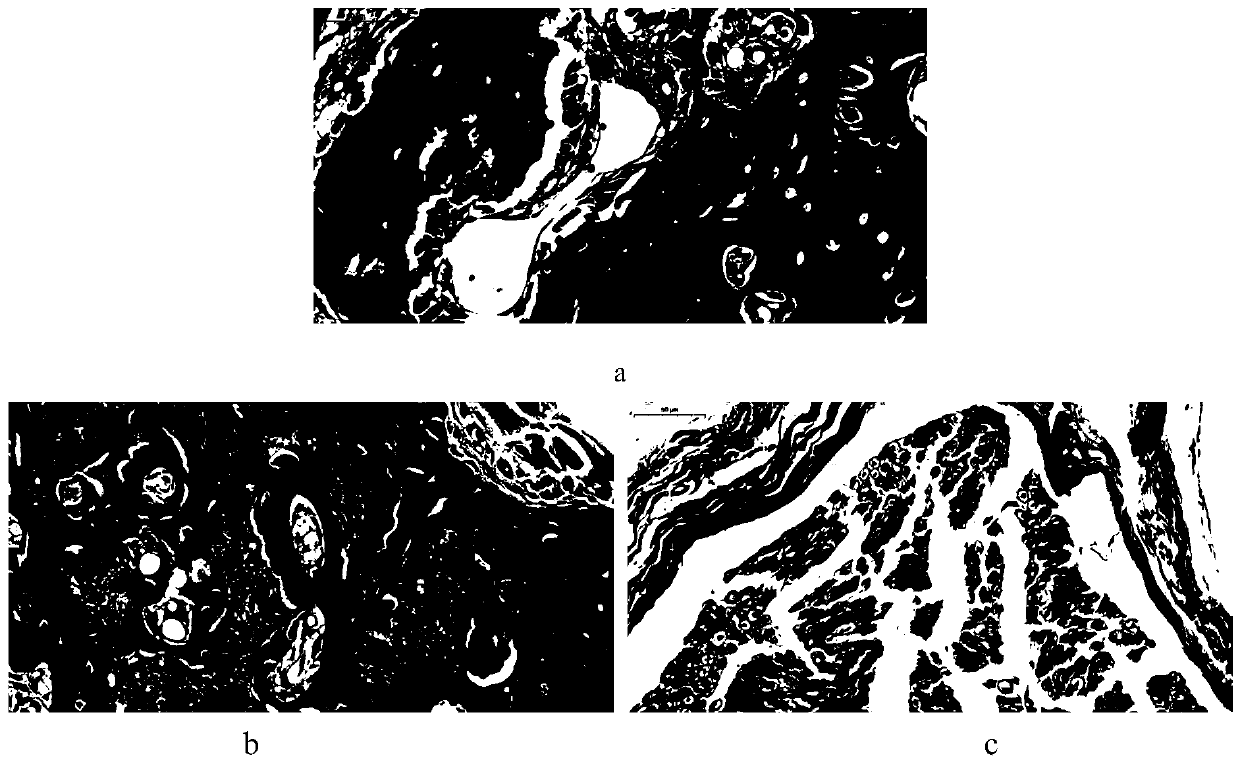

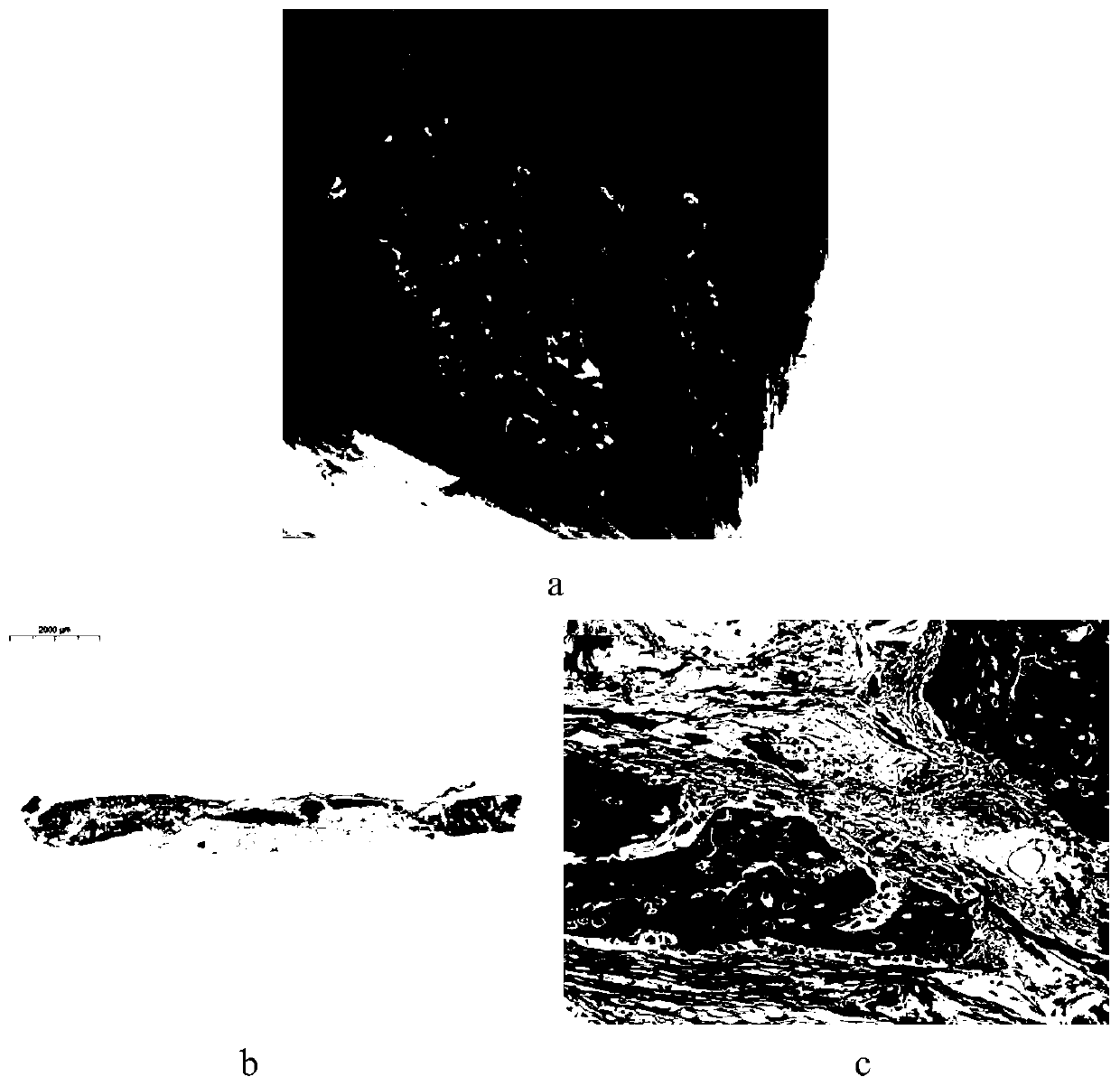

Method used

Image

Examples

Embodiment 1

[0030] A plastic DBM osteoinductive self-curing bone graft material (injection type), prepared by the following method: 20 parts of β-calcium sulfate hemihydrate, 10 parts of calcium sulfate dihydrate, 30 parts of α-TCP, carboxymethyl fiber 5 parts of plain sodium, mechanically milled for 20 minutes to make the powder evenly mixed, then add 2wt% disodium hydrogen phosphate solution according to the solid-to-liquid ratio of 1:1, stir into mud, then add 35 parts of DBM, the DBM bone meal is the same Allogeneic bone powder with a size of 100 μm to 900 μm, and continue to stir for 1 min to make the DBM disperse evenly. Transfer the sample to a syringe, inject it into physiological saline, and leave it for a day without collapsing; inject it into a mold, and then put it into a constant temperature and humidity box (temperature 37°C, humidity 98%) to cure and shape. After curing for 3 days, the compressive strength It is 3.2MPa.

Embodiment 2

[0032] A plastic DBM osteoinductive self-curing bone graft material (face clay type), prepared by the following method: 39 parts of α-calcium sulfate hemihydrate, 1 part of calcium sulfate dihydrate, 20 parts of β-TCP, hydroxypropyl 5 parts of methylcellulose, mechanically milled for 15 minutes to mix the powder evenly, then add water for injection according to the solid-to-liquid ratio of 1:0.9, stir into a slurry, then add 35 parts of DBM, the DBM bone powder is allogeneic bone powder , with a size of 100 μm to 900 μm, continue to stir for 1 min to disperse the DBM evenly. Transfer the sample to a syringe, inject it into physiological saline, and leave it for a day without collapsing; inject it into a mold, and then put it into a constant temperature and humidity box (temperature 37°C, humidity 98%) to cure and shape. After curing for 3 days, the compressive strength is 3.0 MPa.

Embodiment 3

[0034] A plastic DBM osteoinductive self-curing bone graft material (preformed), prepared by the following method: 20 parts of β-calcium sulfate hemihydrate, 10 parts of calcium sulfate dihydrate, 30 parts of α-TCP, carboxymethyl fiber 5 parts of plain sodium, mechanically milled for 20 minutes to make the powder evenly mixed, then add 2wt% disodium hydrogen phosphate solution according to the solid-to-liquid ratio of 1:1, stir into mud, then add 35 parts of DBM, the DBM bone meal is the same Allogeneic bone powder with a size of 100 μm to 900 μm, and continue to stir for 1 min to make the DBM disperse evenly. The sample was filled into the mold, cured and molded in a constant temperature and humidity box (temperature 37°C, humidity 98%), and after curing for 3 days, it was freeze-dried to obtain a preformed product with a compressive strength of 3.9 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com