Preparation method for inorganic microspheres, inorganic microspheres prepared thereby, and application of inorganic microspheres

A microsphere, inorganic technology, applied in inorganic chemistry, chemical instruments and methods, medical science and other directions, can solve the problems of large diameter distribution of microspheres, inability to obtain inorganic microspheres, and low proportion of inorganic components, and achieve reproducibility. The effect of good performance, avoid deterioration and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

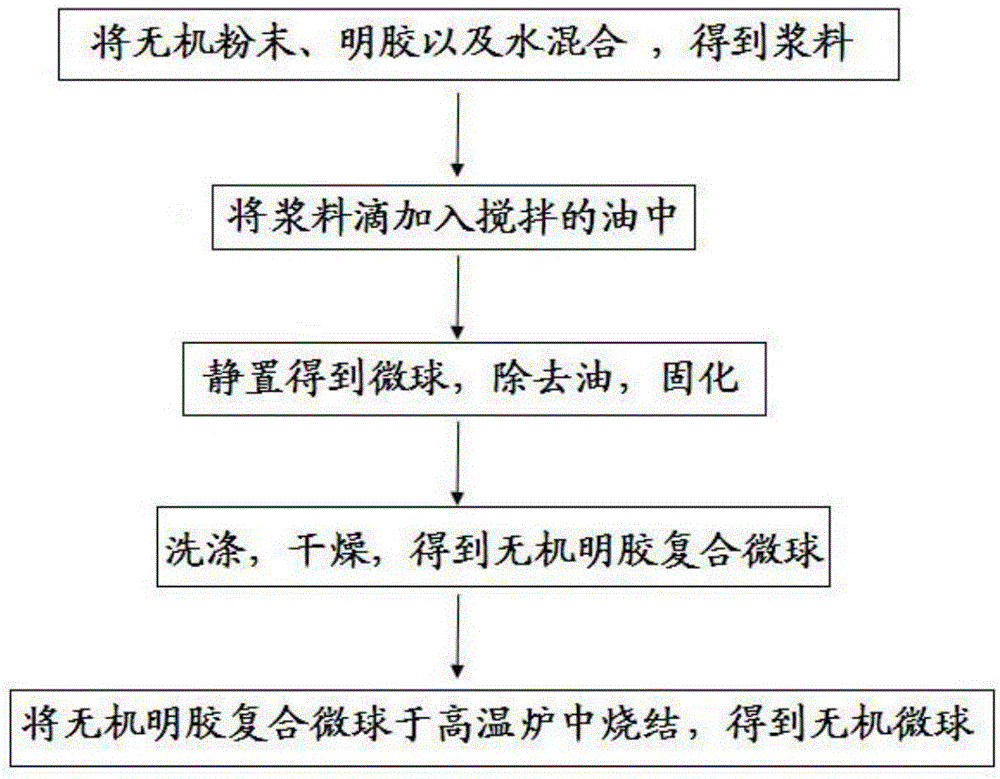

[0045] The present invention provides a preparation method of inorganic microspheres and the inorganic microspheres prepared therefrom and its use. The inorganic components of the obtained inorganic microspheres have a high proportion, and after burning off the organic components at high temperature, complete inorganic microspheres can be obtained. , and inorganic microspheres of various diameter ranges can be obtained. The preparation process of the invention is simple, and the microspheres can be formed directly through sintering, which can prevent the moisture-sensitive powder from deteriorating when forming the microspheres.

[0046] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0047] In the preparation method of the inorganic microspheres in the embodiment of the present application, gelatin ...

Embodiment 1

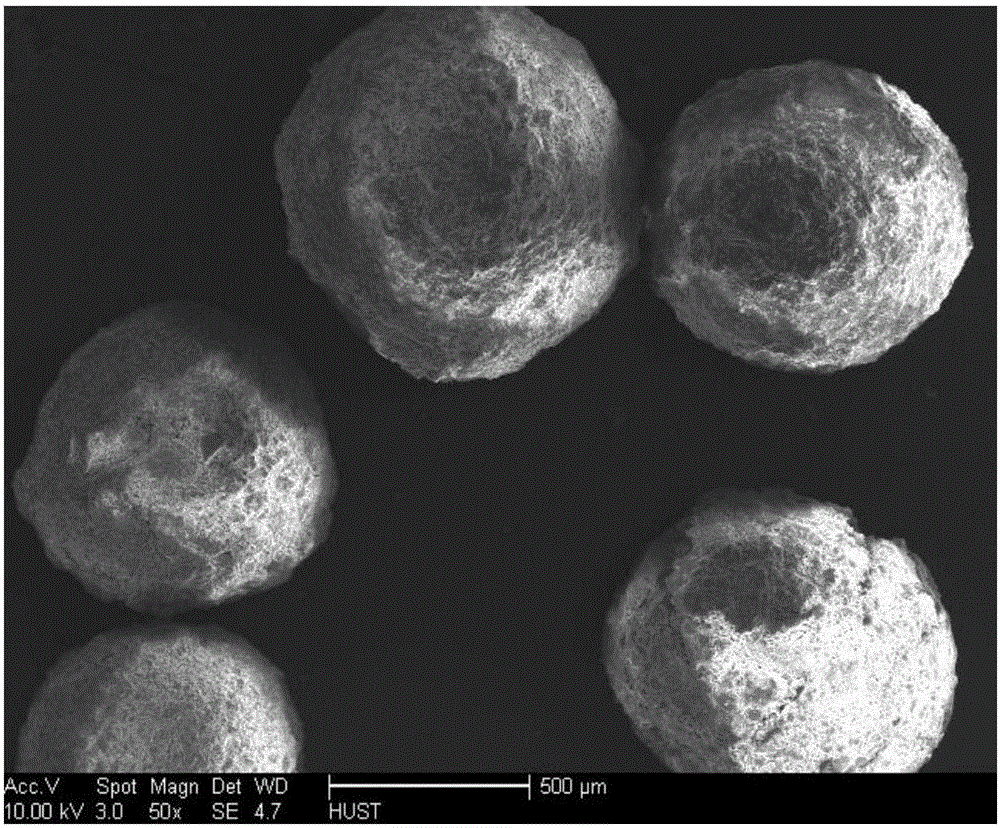

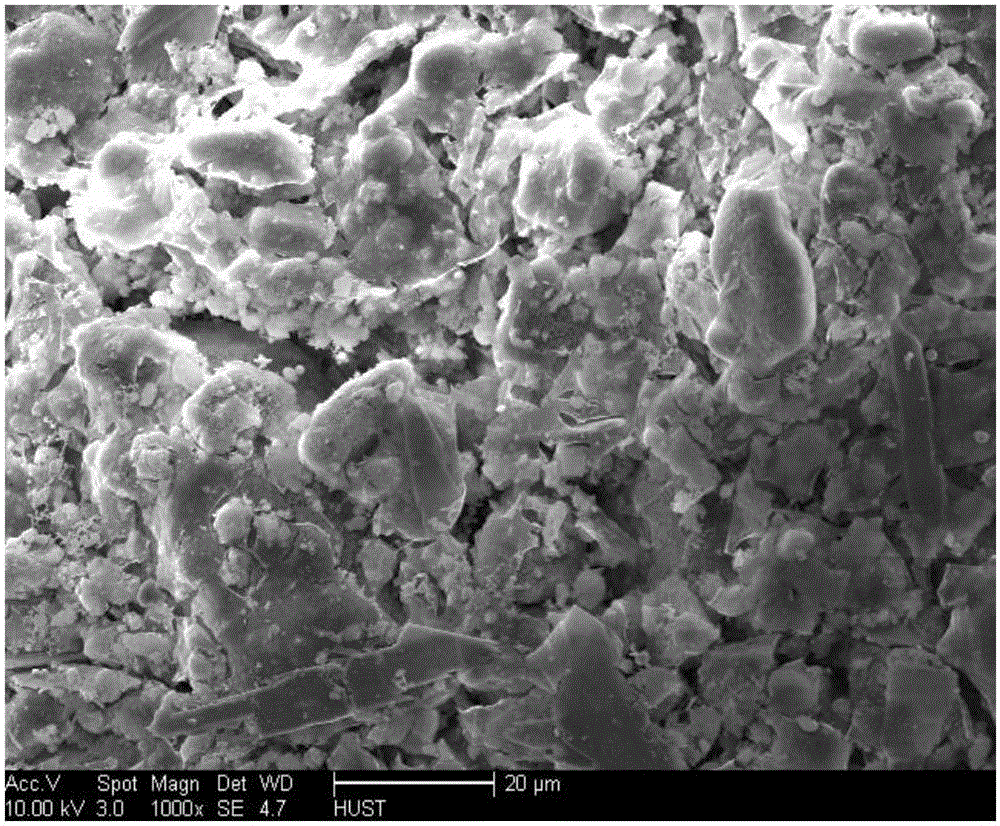

[0067] Prepare a gelatin solution with a mass fraction of 15%; add 250mL simethicone oil to a 500mL beaker and place it in a -20°C refrigerator for pre-cooling; install a mechanical stirrer. Take a 5mL centrifuge tube, add 0.2g amorphous calcium phosphate, add 1024μL deionized water, stir well; add 226μL gelatin solution, stir well, inhale into a 1mL syringe in a 70°C water bath, and put the syringe in a 70°C water bath to keep warm . Take out the pre-cooled simethicone beaker and place it under the mechanical stirrer. The mechanical stirring rod goes deep into the bottom of the beaker to raise the temperature of the simethicone to -4°C and start stirring at 280rpm. Take out the syringe, slowly drop into simethicone, stir for about 3 minutes, and let it stand for 1 hour. Remove the simethicone, wash it twice with acetone, add a glutaraldehyde solution with a mass fraction of 2.5%, and after 3 hours, remove the glutaraldehyde solution, wash it twice with absolute ethanol, and ...

Embodiment 2

[0070] Prepare a gelatin solution with a mass fraction of 15%; add 250mL benzyl silicone oil to a 500mL beaker and place it in a -20°C refrigerator for pre-cooling; install a mechanical stirrer. Take a 5mL centrifuge tube, add 874μL deionized water to 0.2g amorphous calcium phosphate, stir well; add 150μL polyvinyl alcohol solution (containing 0.02g polyvinyl alcohol), stir well; add 226μL gelatin solution, stir well, in Inhale into a 1mL syringe in a water bath at 80°C, and place the syringe in a water bath at 80°C to keep warm. Take out the pre-cooled simethicone beaker and place it under the mechanical stirrer. The mechanical stirring rod goes deep into the bottom of the beaker to raise the temperature of the simethicone to 1°C and start stirring at 250rpm. Take out the syringe, slowly drop into simethicone, stir for about 3 minutes, and let it stand for 1 hour. Remove the simethicone, wash it twice with acetone, add a glutaraldehyde solution with a mass fraction of 2.5%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com