A kind of preparation method of silicon-doped α-tricalcium phosphate ceramics

A technology of tricalcium phosphate and ceramics, which is applied in the field of preparation of silicon-doped α-tricalcium phosphate ceramics, can solve the problems of energy consumption, large grain size and high preparation temperature, achieve stable α-TCP phase, overcome grain size Coarse, energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

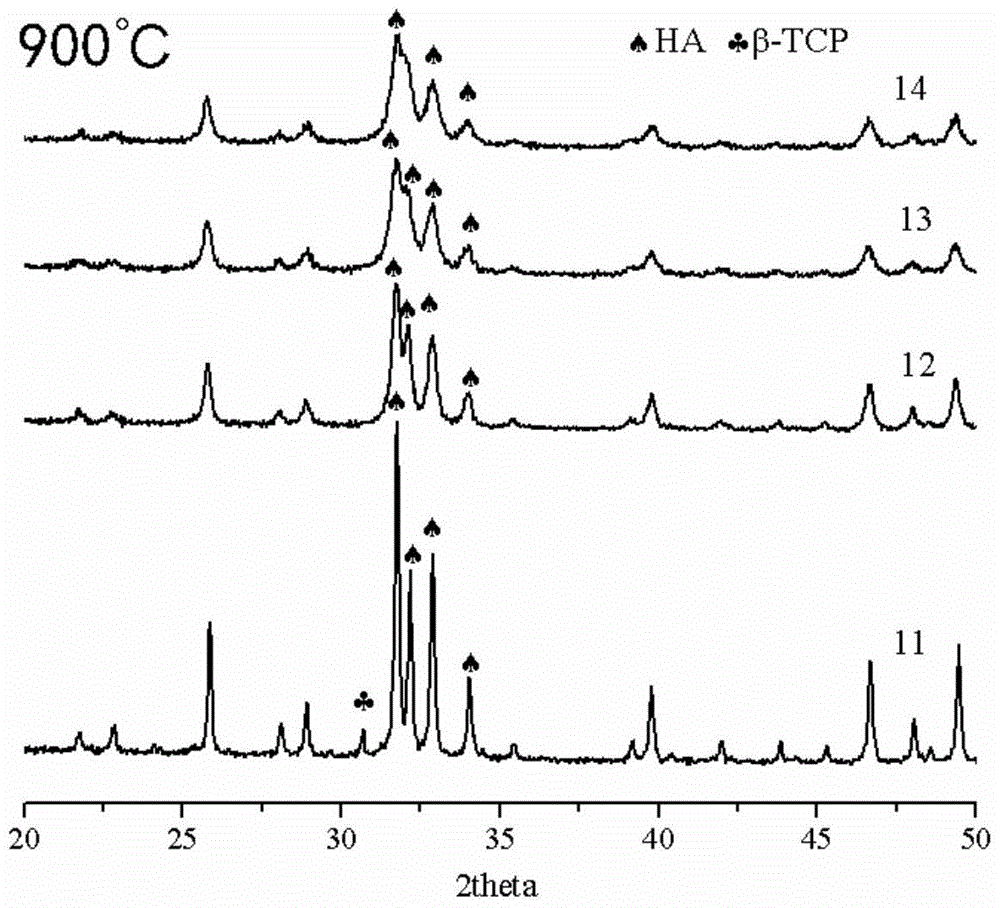

[0038] The preparation of silicon-doped α-TCP in this embodiment, in this embodiment, the silicon doping amount (relative to the precursor nano-silicon-doped hydroxyapatite powder) is 0-4.0wt%, including the following steps:

[0039] (1) Prepare 0.5mol / L Ca(NO 3 ) 2 4H 2 O solution and 0.25mol / L (NH 4 ) 3 PO 4 ·3H 2 O solution was used as calcium source and phosphorus source respectively, and tetraethyl orthosilicate (TEOS) was used as silicon source. Adjust the amount of calcium source, phosphorus source and silicon source to control the molar ratio of Ca / (P+Si) to 1.67; use ammonia water to adjust the pH of the calcium source to be greater than 11, and the pH of the phosphorus source to be greater than 10, and add the dispersant polyethylene glycol (6000) Stir the calcium source for 30 minutes, add tetraethyl orthosilicate to the phosphorus source and stir for 30 minutes; add the mixed solution of the silicon source and the phosphorus source to the calcium source drop ...

Embodiment 2

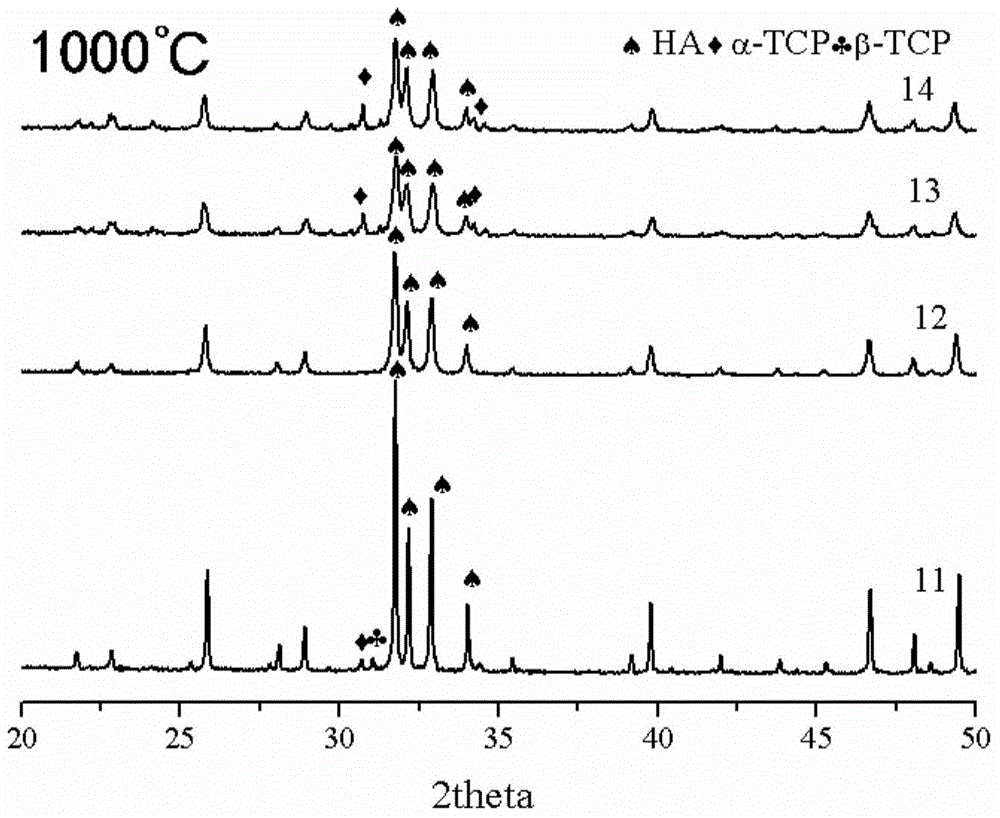

[0046] The preparation of silicon-doped α-TCP in this embodiment, the amount of silicon doped in this embodiment (relative to the precursor silicon-doped hydroxyapatite powder) is 0 ~ 4.0wt%, including the following steps:

[0047] (1) Prepare 0.5mol / L Ca(NO 3 ) 2 4H 2 O solution and 0.25mol / L (NH 4 ) 3 PO 4 ·3H 2 O solution was used as calcium source and phosphorus source respectively, and tetraethyl orthosilicate (TEOS) was used as silicon source. Adjust the amount of calcium source, phosphorus source and silicon source to control the molar ratio of Ca / (P+Si) to 1.67; use ammonia water to adjust the pH of the calcium source to be greater than 11, and the pH of the phosphorus source to be greater than 10, and add the dispersant polyethylene glycol (6000) Stir the calcium source for 20 minutes, add tetraethyl orthosilicate to the phosphorus source and stir for 20 minutes; add the mixed solution of the phosphorus source and the silicon source to the calcium source drop by...

Embodiment 3

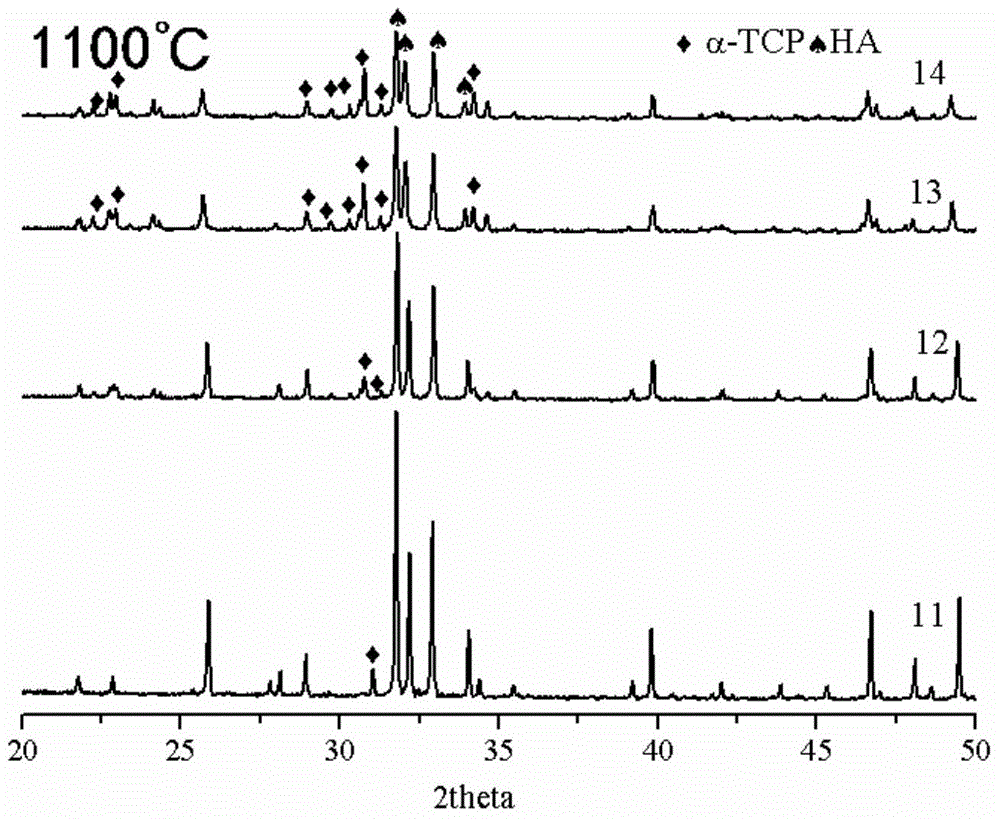

[0054] The preparation of silicon-doped α-TCP in this embodiment, in this embodiment, the silicon doping amount (relative to the precursor silicon-doped hydroxyapatite) is 0-4.0wt%, including the following steps:

[0055] (1) Prepare 0.5mol / L Ca(NO 3 ) 2 4H 2 O solution and 0.25mol / L (NH 4 ) 3 PO 4 ·3H 2 O solution was used as calcium source and phosphorus source respectively, and tetraethyl orthosilicate (TEOS) was used as silicon source. Adjust the amount of calcium source, phosphorus source and silicon source to control the molar ratio of Ca / (P+Si) to 1.67; use ammonia water to adjust the pH of the calcium source to be greater than 11, and the pH of the phosphorus source to be greater than 10, and add the dispersant polyethylene glycol (6000) Stir the calcium source for 30 minutes, add tetraethyl orthosilicate to the phosphorus source and stir for 30 minutes; add the mixed solution of the silicon source and the phosphorus source to the calcium source drop by drop at 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com