Biological porous bone cement prepared by compositing Sr-doped calcium-phosphorus bioglass and alpha-tricalcium phosphate and preparation method thereof

A technology of biological glass and tricalcium phosphate, which is applied in ceramic products, applications, household appliances, etc., can solve the problems of low compressive strength of bone cement, unfavorable vascular ingrowth and body fluid circulation, and difficulty in forming a porous structure, so as to facilitate the production of body fluids. The effects of circulation, good application prospects, and fast dissolution speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

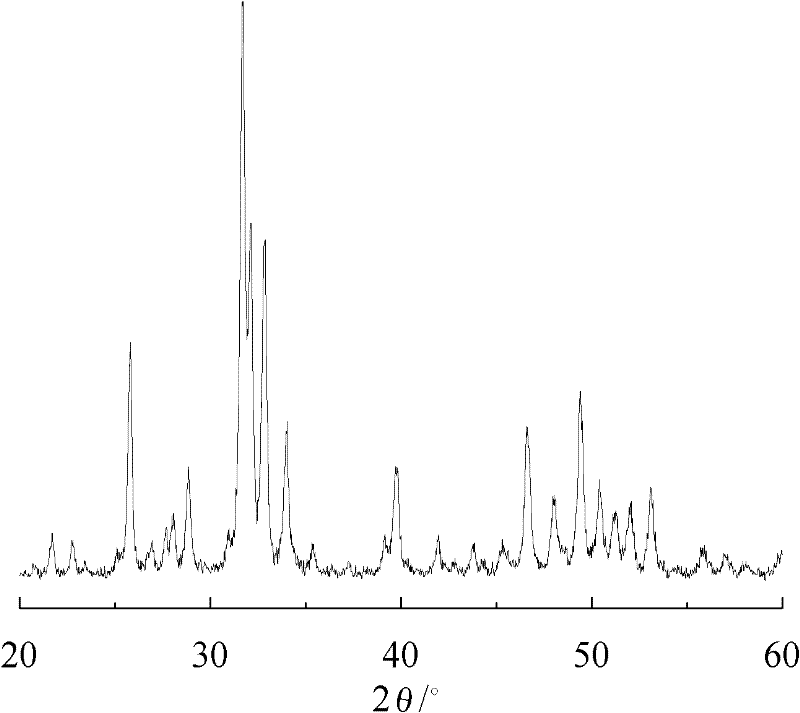

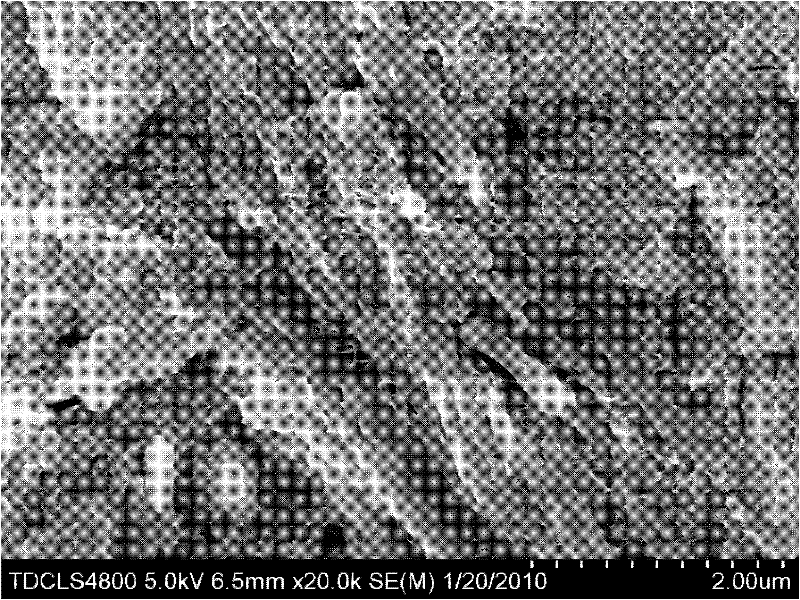

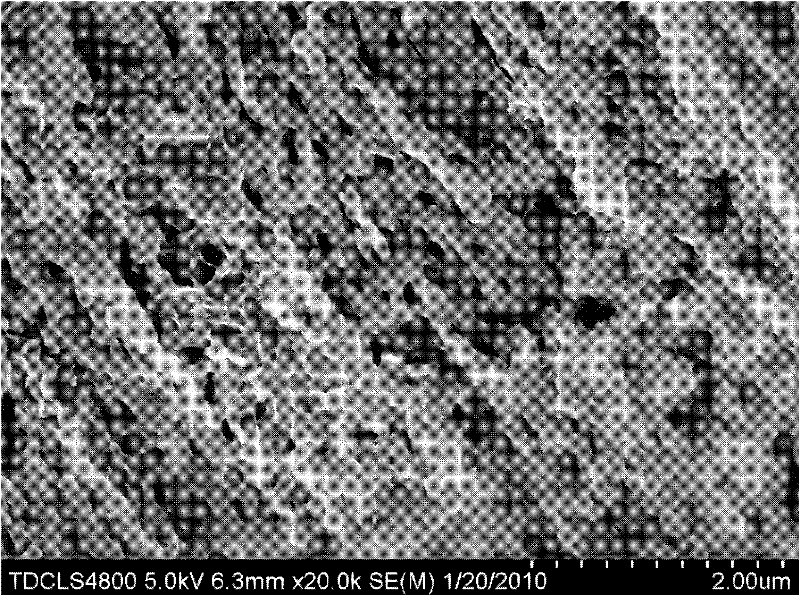

Image

Examples

Embodiment 1

[0022] Step 1: Preparation of Sr-doped calcium phosphorus bioglass

[0023] Calcium nitrate tetrahydrate, phosphorus pentoxide, strontium nitrate, and sodium nitrate are used as raw materials, and the corresponding substances are weighed in molar ratios, so that the oxides corresponding to each substance in the raw materials are calculated according to CaO:P 2 o 5 :SrO:Na 2 The molar percentage of O is 50:40:3:7 to prepare calcium phosphorus bioglass. 8.517g P 2 o 5 Dissolve in 40ml of absolute ethanol, control the temperature not to exceed 38.0°C during the addition process, stir until the solution becomes a clear and transparent phosphorus-based precursor solution, and let the solution stand for 24 hours before use. Weigh 0.952gSr(NO 3 ) 2 , 17.711g Ca(NO 3 ) 2 4H 2 O, 1.785g NaNO 3 , dissolved in 45ml of distilled water in this order to form a transparent and clear solution. The obtained solution was added dropwise to the phosphorus-based precursor solution to ob...

Embodiment 2

[0029] Step 1: Preparation of Sr-doped calcium phosphorus bioglass

[0030] Except that the molar percentages of calcium nitrate tetrahydrate and strontium nitrate in the bioglass are different, other operations are the same as step 1 in Example 1. Calcium nitrate tetrahydrate, phosphorus pentoxide, strontium nitrate, and sodium nitrate are used as raw materials, and the corresponding substances are weighed in molar ratios, so that the oxides corresponding to each substance in the raw materials are calculated according to CaO:P 2 o 5 :SrO:Na 2 The molar percentage of O is 44:40:9:7 to prepare calcium phosphorus bioglass. 8.517g P 2 o 5 Dissolve in 40ml of absolute ethanol, control the temperature not to exceed 38.0°C during the addition process, stir until the solution becomes a clear and transparent phosphorus-based precursor solution, and let the solution stand for 24 hours before use. Weigh 2.857gSr(NO 3 ) 2 , 15.586g Ca(NO 3 ) 2 4H 2 O, 1.785g NaNO 3 , dissolved...

Embodiment 3

[0034] Step 1: Preparation of Sr-doped calcium phosphorus bioglass

[0035] Except that the molar percentages of calcium nitrate tetrahydrate and strontium nitrate in the bioglass are different, other operations are the same as step 1 in Example 1. Calcium nitrate tetrahydrate, phosphorus pentoxide, strontium nitrate, and sodium nitrate are used as raw materials, and the corresponding substances are weighed in molar ratios, so that the oxides corresponding to each substance in the raw materials are calculated according to CaO:P 2 o 5 :SrO:Na 2 The molar percentage of O is 42:40:11:7 to prepare calcium phosphorus bioglass. 8.517gP 2 o 5 Dissolve in 40ml of absolute ethanol, control the temperature not to exceed 38.0°C during the addition process, stir until the solution becomes a clear and transparent phosphorus-based precursor solution, and let the solution stand for 24 hours before use. Weigh 3.492g Sr(NO 3 ) 2 , 15.586g Ca(NO 3 ) 2 4H 2 O, 1.785g NaNO 3 , dissolve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com