Two-phase alpha-tricalcium phosphate/oxyhydrogen-base apatite bone cement and its preparing process

A technology of hydroxyapatite and calcium phosphate, applied in medical science, prosthesis, coating, etc., can solve the problems of limited efficacy and inability to contact with bone tissue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Weigh 0.219 grams of ammonium phosphate (AP) powder and dissolve it in deionized water, then pour a fixed amount of 20 grams of hydroxide apatite (HAP) powder into the AP solution and mix it uniformly, and then in a 70°C Dry in the oven for three days. The dried powder mixture of AP and HAP was placed in a platinum crucible, and the temperature was raised to 1350°C at a heating rate of 10°C / min in a programmable SiC high-temperature furnace, and the temperature was kept at 1350°C for one hour, and then cooled rapidly , which is rapidly cooled from 1350°C to room temperature, so that a two-phase crystal composition with a weight composition ratio of α-tricalcium phosphate / hydroxyapatite of 10 / 90 (hereinafter referred to as A10H90) can be obtained.

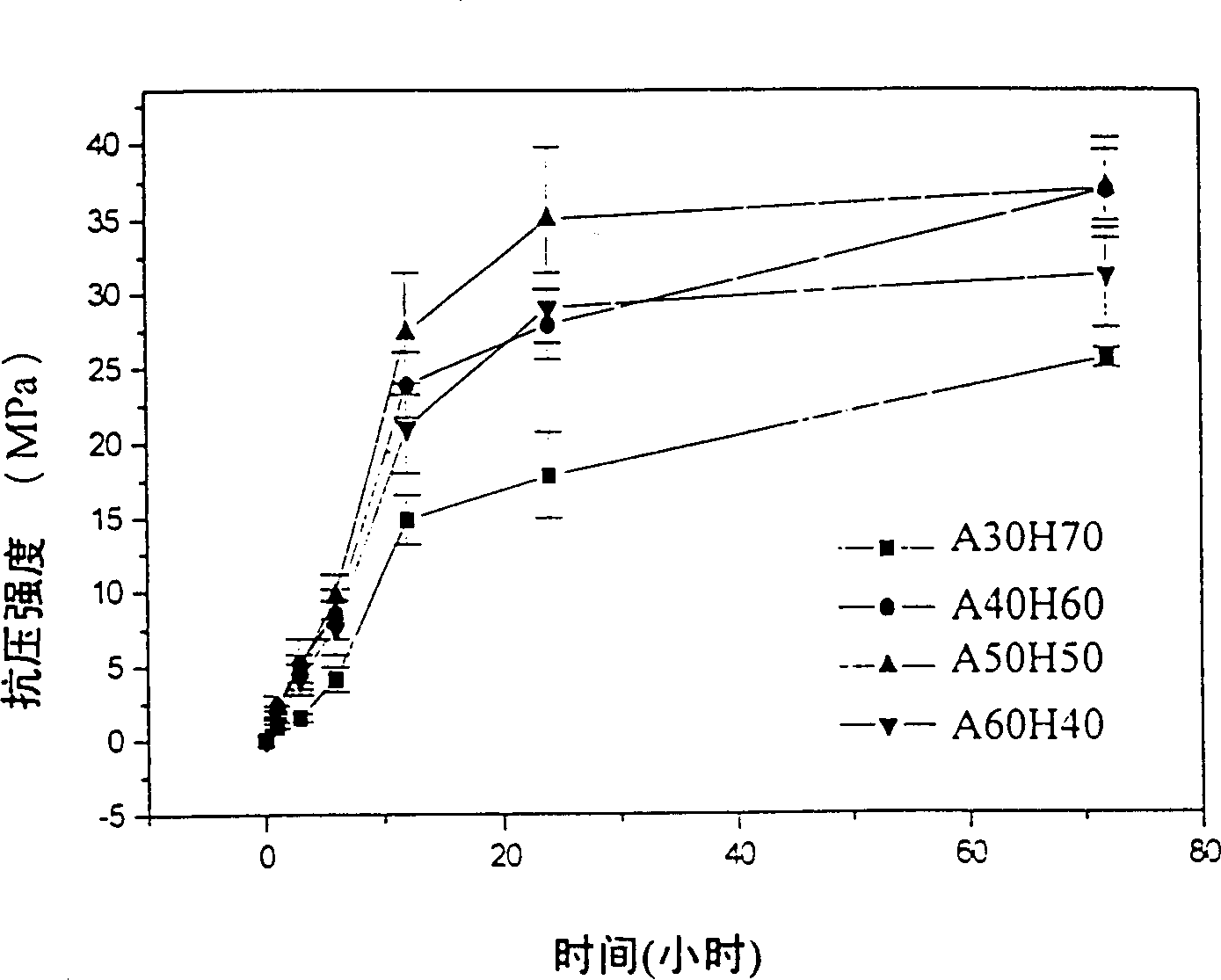

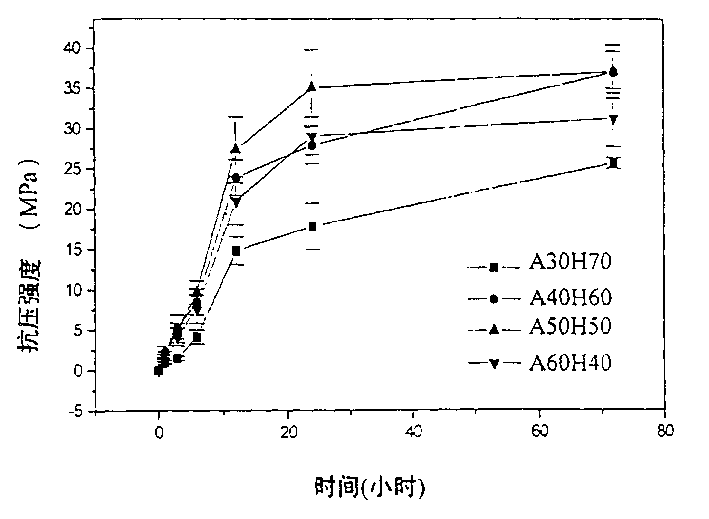

Embodiment 2 to 9

[0027] Repeat the steps of Example 1, but take different weights of ammonium phosphate (AP) powders to obtain α-tricalcium phosphate / hydroxyapatite weight composition ratios of 20 / 80, 30 / 70, 40 / 60 , 50 / 50, 60 / 40, 70 / 30, 80 / 20, 90 / 10 products (respectively referred to as A20H80, A30H70, A40H60, A50H50, A60H40, A70H30, A80H20, A90H10), as shown in Table 1.

[0028] Table I:

[0029] Example

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com