Modified steel slag cement

A steel slag and modification technology, applied in cement production, etc., can solve problems such as poor stability, poor mechanical strength, and low strength, and achieve the effects of improving mechanical strength, reducing porosity, and reducing pore channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

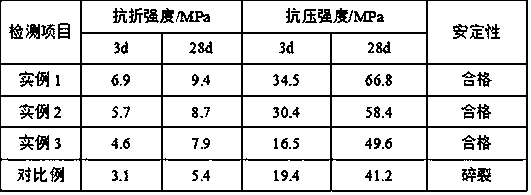

Examples

example 1

[0023] Put bagasse in a steam explosion tank, under the conditions of temperature 220°C and pressure 1.0MPa, hold the pressure for 45s, release the pressure and discharge to obtain steam explosion bagasse; Bagasse, 2 parts of biogas slurry and 30 parts of water were placed in a fermenter, stirred and mixed for 30 minutes at a rotating speed of 200 r / min, fermented for 3 days to obtain a fermented liquid, and filtered the fermented liquid to obtain a filter cake, which was filtered The cake was dried in a vacuum freeze-drying oven until the water content was 10% to obtain pretreated bagasse; the pretreated bagasse was placed in a fluidized bed reactor, and the loaded Nitrogen gas with trimethylaluminum is fed continuously for 30 minutes to obtain modified bagasse; the steel slag is pulverized in a ball mill, and then passed through an 80-mesh sieve to obtain steel slag powder; the obtained steel slag powder is mixed with 10% sulfuric acid Put it in a beaker with a mass ratio of...

example 2

[0025]Put bagasse in a steam explosion tank, under the conditions of temperature 220°C and pressure 1.0MPa, hold the pressure for 45s, release the pressure and discharge to obtain steam explosion bagasse; Bagasse, 2 parts of biogas slurry and 30 parts of water were placed in a fermenter, stirred and mixed for 30 minutes at a rotating speed of 200 r / min, fermented for 3 days to obtain a fermented liquid, and filtered the fermented liquid to obtain a filter cake, which was filtered The cake was dried in a vacuum freeze-drying oven until the water content was 10% to obtain pretreated bagasse; the pretreated bagasse was placed in a fluidized bed reactor, and the loaded Nitrogen gas with trimethylaluminum is fed continuously for 30 minutes to obtain modified bagasse; the steel slag is pulverized in a ball mill, and then passed through an 80-mesh sieve to obtain steel slag powder; the obtained steel slag powder is mixed with 10% sulfuric acid Put it in a beaker with a mass ratio of ...

example 3

[0027] Put the steel slag into a ball mill to pulverize it, and then pass it through a 80-mesh sieve to obtain steel slag powder; put the obtained steel slag powder and sulfuric acid with a mass fraction of 10% in a beaker at a mass ratio of 1:30, and at a speed of 400r / min, Stir the reaction to obtain a reaction mixture, put the reaction mixture in a refrigerator, and freeze it at -20°C for 2 hours to obtain a frozen block, then thaw the frozen block in hot water at 80°C, and freeze in this way, The thawing cycle is 8 times to obtain the thawed mixed solution, and then the thawed mixed solution is filtered to obtain the filter residue, and then the filter residue is placed in an oven and dried for 2 hours to obtain the pretreated steel slag powder; 1:20 placed in a mixing ball mill, under the condition of rotating speed of 400r / min, the ball mill was stirred and mixed for 30min, then placed in a muffle furnace, and calcined for 40min at a temperature of 800°C to obtain calcine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com