Composite biological material capable of injecting bioglass-calcium phosphate bone cement and preparation

A technology of calcium phosphate bone cement and composite biomaterials, which is applied in the field of biomedical repair materials, can solve the problems of low mechanical properties, low HAp degradation rate, and limited bone tissue generation, and achieve high mechanical properties, stable chemical bonding, and effective Good for growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

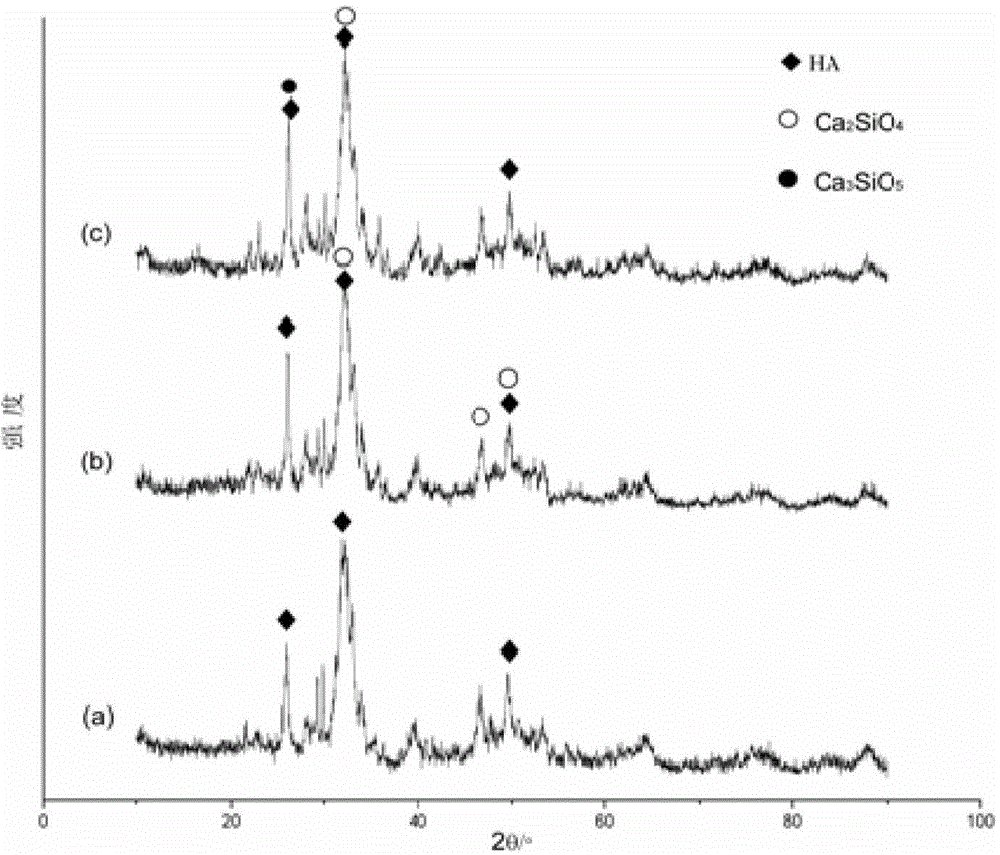

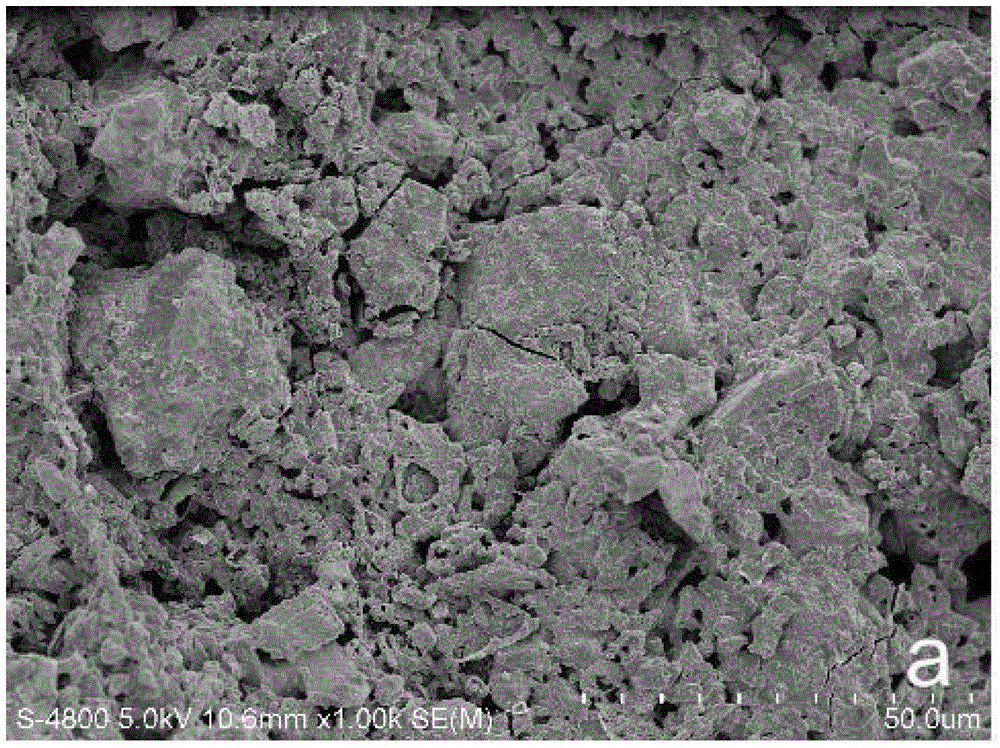

Embodiment 1

[0036] Step 1: Preparation of 45S5 bioglass

[0037] The main raw materials of 45S5 bioglass are silicon dioxide, sodium carbonate, calcium carbonate, calcium fluoride, potassium carbonate and phosphorus pentoxide. Raw material according to a certain ratio (51.20wt%SiO 2 ,3.55wt%NaCO 3 ,18.86wt%CaCO 3 ,8.19wt%CaF 2 ,7.47wt%K 2 CO 3 and 10.73wt%P 2 o 5 ) mixed evenly, melted in a high-temperature glass lift furnace at 1170°C for 40 minutes, then quickly poured into deionized water for water quenching, filtered out the bioglass and dried it in a blast drying oven at 70°C for 1 hour, and put it in an agate mortar Grinding, taking bioglass with a particle size of about 10 microns, that is, obtaining 45S5 bioglass for future use.

[0038] Step 2: Preparation of bioglass-calcium phosphate bone cement composite biomaterial

[0039] Add 45S5 bioglass to the bone cement to form a solid phase powder according to 5% of the total weight of the solid phase powder (that is, calcium...

Embodiment 2

[0043] Step 1: Same as Example 1.

[0044] Step 2: Preparation of bioglass-calcium phosphate bone cement composite biomaterial

[0045] Add 45S5 bioglass to the bone cement at 5% of the total weight of the solid powder (that is, calcium phosphate bone cement + bioglass) to form a solid phase powder. The calcium phosphate bone cement is composed of tetracalcium phosphate and anhydrous hydrogen phosphate Calcium mixed composition, the molar ratio of the two is 1:1, the average particle size is about 6 microns, and the liquid phase (solidified liquid) is 1M potassium dihydrogen phosphate and dipotassium hydrogen phosphate aqueous solution.

[0046] The ratio of the solid phase powder to the liquid phase (solidified liquid) is 3.0 g / ml to form a paste. The curing time of the obtained injectable bioglass-calcium phosphate bone cement composite biomaterial was 12±1.2 min, which indicated that increasing the solid-liquid ratio could further shorten the curing time.

[0047] Fill th...

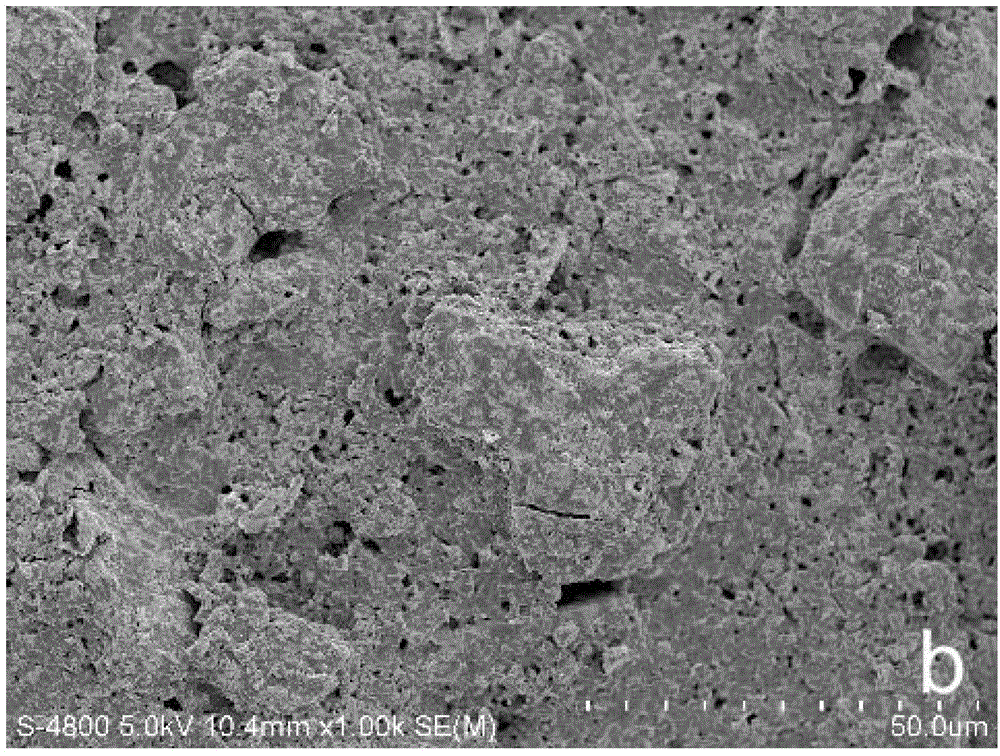

Embodiment 3

[0049] Step 1: Same as Example 1.

[0050] Step 2: Preparation of bioglass-calcium phosphate bone cement composite biomaterial

[0051] Add 45S5 bioglass to the bone cement according to 20% of the total weight (calcium phosphate bone cement + bioglass) to form a solid phase powder. Among them, the calcium phosphate bone cement is composed of tetracalcium phosphate and anhydrous calcium hydrogen phosphate. The molar ratio of them is 1:1, and the average particle size is about 6 microns; the liquid phase (solidified liquid) is 1M potassium dihydrogen phosphate and dipotassium hydrogen phosphate aqueous solution.

[0052] The ratio of the solid phase powder to the liquid phase (solidified liquid) is 2.0 g / ml to form a paste. The resulting injectable bioglass-calcium phosphate bone cement composite biomaterial had a curing time of 21 ± 1.4 min, indicating that the addition of 20 wt% 45S5 bioglass prolongs the curing time of CPC.

[0053] Fill the reconciled paste into a stainles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com