Ceramic matrix composite material and preparation method thereof

A composite material and ceramic-based technology, applied in the field of composite materials, to achieve the effects of good toughness, uniform distribution, and outstanding high-temperature mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

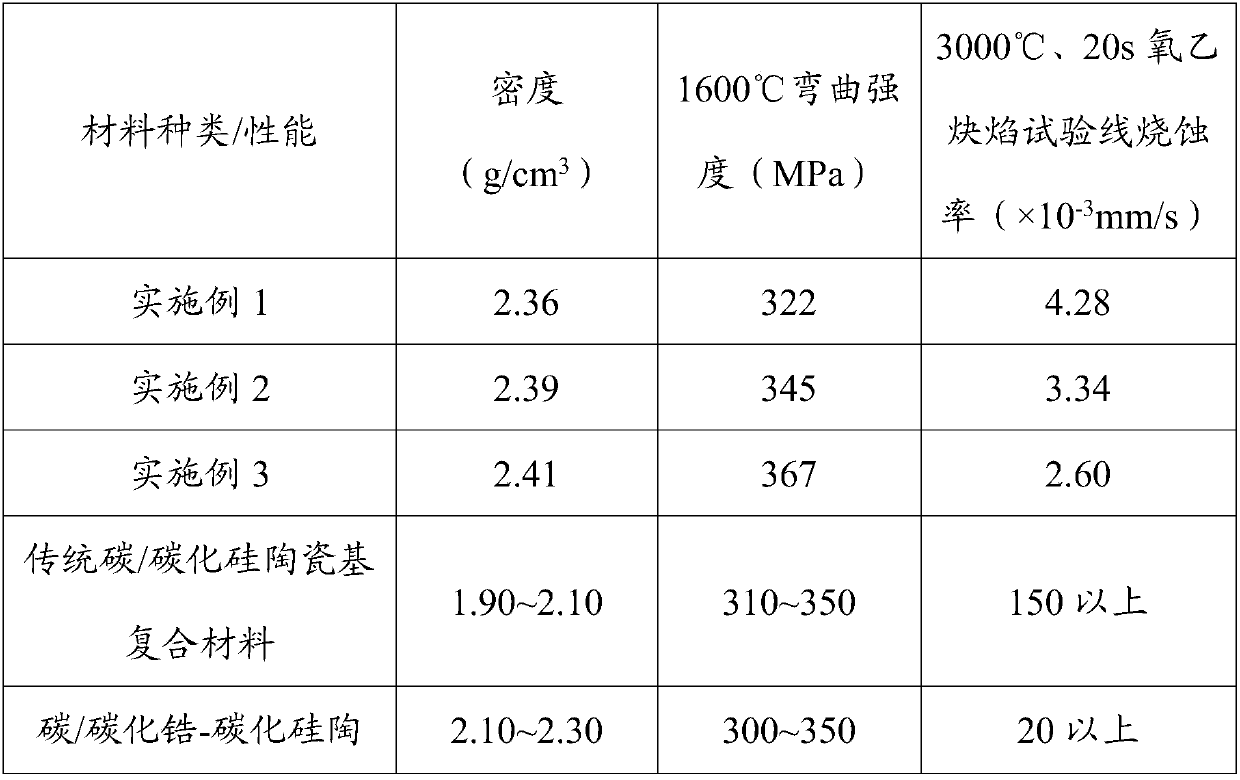

Examples

Embodiment 1

[0050] A method for preparing a carbon / hafnium-tantalum solid solution-silicon carbide ultra-high temperature ceramic matrix composite material, the specific steps are:

[0051] 1) The needle-punched carbon fiber reinforcement was treated at a high temperature of 1700°C for 2 hours, and then deposited in a vapor deposition furnace for 150 hours, 120 hours, and 100 hours respectively, so that the density of the fiber reinforcement reached 1.10 g / cm 3 ;

[0052] 2) 5 kilograms of hafnium-tantalum copolymer resin, 1 kilogram of polycarbosilane and 6 kilograms of allylphenol were mechanically stirred for 5 hours, and after standing for 10 hours, a hafnium-tantalum-silicon ternary composite ceramic precursor solution was prepared;

[0053] 3) Immerse the fiber reinforcement obtained in 1) in the precursor solution of 2), and the immersion conditions are: immersion in a vacuum of 100KPa for 2 hours, and then immersion in a pressure of 3MPa for 2 hours. Finally, further pressurize t...

Embodiment 2

[0062] A method for preparing a carbon / hafnium-tantalum solid solution-silicon carbide ultra-high temperature ceramic matrix composite material, the specific steps are:

[0063] 1) Treat the stitched carbon fiber reinforcement at a high temperature of 1700°C for 2 hours, and then deposit it in a vapor deposition furnace for 150 hours, 100 hours, and 100 hours respectively, so that the density of the fiber reinforcement reaches 1.20 g / cm 3 ;

[0064] 2) 5 kilograms of hafnium-tantalum copolymer resin, 1 kilogram of polycarbosilane and 6 kilograms of allylphenol were mechanically stirred for 5 hours, and after standing for 10 hours, a hafnium-tantalum-silicon ternary composite ceramic precursor solution was prepared;

[0065] 3) Immerse the fiber reinforcement obtained in 1) in the precursor solution of 2), and the immersion conditions are: immersion in a vacuum of 100KPa for 2 hours, and then immersion in a pressure of 3MPa for 2 hours. Finally, further pressurize to 10MPa, he...

Embodiment 3

[0074] A method for preparing a carbon / hafnium-tantalum solid solution-silicon carbide ultra-high temperature ceramic matrix composite material, the specific steps are:

[0075] 1) Treat the finely woven and punctured carbon fiber reinforcement at a high temperature of 1700°C for 2 hours, and then deposit it in a vapor deposition furnace for 150 hours, 100 hours, and 100 hours respectively, so that the density of the fiber reinforcement reaches 1.23g / cm 3 ;

[0076] 2) 5 kilograms of hafnium-tantalum copolymer resin, 1 kilogram of polycarbosilane and 6 kilograms of allylphenol were mechanically stirred for 5 hours, and after standing for 10 hours, a hafnium-tantalum-silicon ternary composite ceramic precursor solution was prepared;

[0077] 3) Immerse the fiber reinforcement obtained in 1) in the precursor solution of 2), and the immersion conditions are: immersion in a vacuum of 100KPa for 2 hours, and then immersion in a pressure of 3MPa for 2 hours. Finally, further pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cracking temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com