Method for preparing inflaming-retarding wool fabric and inflaming-retarding working solution

A working fluid and fabric technology, which is used in the post-finishing of natural fiber fabrics and the flame-retardant finishing of wool, can solve the problems of non-washable, harmful, and unclear physiological functions of flame-retardant wool fabrics, and achieve excellent flame-retardant performance. , easy to industrialize production, the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

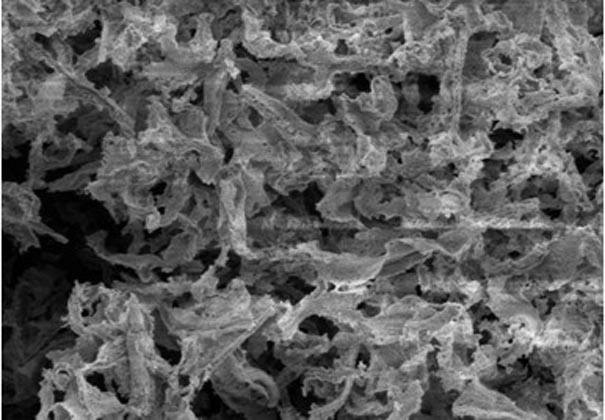

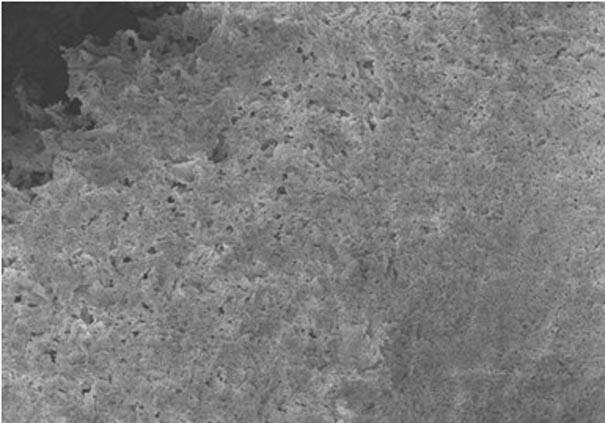

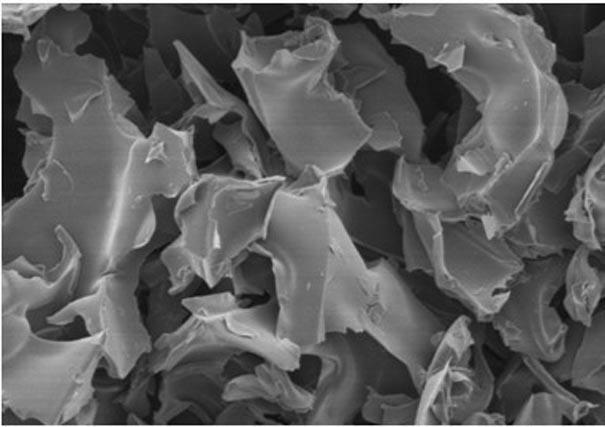

Image

Examples

Embodiment 1

[0023] Embodiment 1: A kind of flame retardant working liquid for preparing flame retardant wool fabric, by weight, the proportion is as follows:

[0024]

[0025] The rest is water.

[0026] The wool fabric to be treated is a pre-treated white cloth with a gram weight of 234g / cm 2 . The processing flow is as follows:

[0027] Preparation of working liquid → immerse the wool fabric in the working liquid for 1 minute, double dipping and rolling (95% rolling rate) → 102°C saturated steam steaming for 10 minutes → washing → drying.

Embodiment 2

[0029] The proportion of flame retardant working fluid by weight is as follows:

[0030]

[0031] The rest is water.

[0032] The wool fabric used is mercerized wool white cloth with a weight of 150g / cm 2 .

[0033] The processing flow is as follows:

[0034] Prepare the working solution → soak the wool fabric in the working solution for 1 minute, then soak twice and roll twice (95% rolling rate) → steam with saturated steam at 101°C for 8 minutes → wash with water → dry.

[0035] The flame retardant performance of treated wool is shown in Table 1:

[0036] Flame retardant properties of wool after treatment in table 1

[0037]

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com