Method for preparing UHTC (Ultra-High Temperature Ceramic) matrix composite material through modification of UHTC powder basal body

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of preparation of ultra-high temperature ceramic matrix composite materials, can solve problems such as fiber erosion, material mechanical properties and poor ablation performance, achieve uniform distribution, improve ablation resistance, and ensure The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

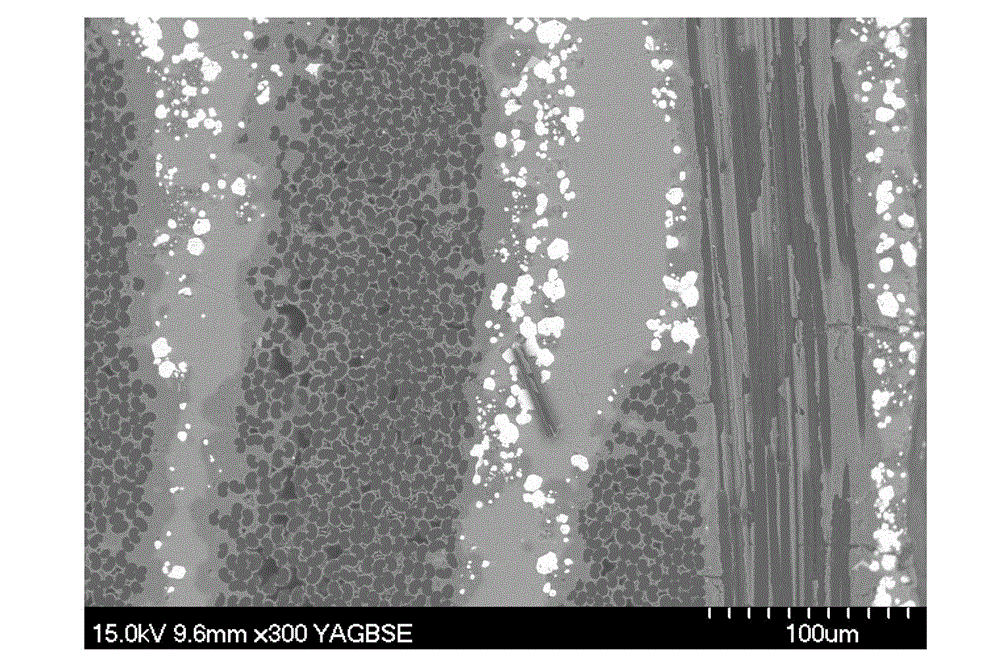

Image

Examples

example 1

[0021] Step 1: Preparation of composite material preform: Clean the C / SiC composite material preform with an open porosity of 30vol%-40vol% with ultrasonic waves for at least 30 minutes, and dry it in an oven at 80℃-100℃ for later use.

[0022] Step 2: Slurry Preparation: ZrB 2 Slurry A was prepared by adding 0.5%-1% mass fraction of sodium cellulose (CMC) aqueous solution to the powder and ball milling for more than 24 hours. Slurry B was prepared by dissolving phenolic resin and hexamethylenetetramine in absolute alcohol in a mass ratio of 10:1. The viscosity of the above slurry is controlled by the content of anhydrous alcohol or aqueous solution to about 60 mPa·s, and the dispersibility is controlled by adjusting the pH value (greater than 11).

[0023] Step 3: Vacuum pressure impregnation: the C / SiC preform of step 1 is first vacuum impregnated with slurry A for about 30 minutes, then pressurized to 0.8MPa pressure by inert gas to impregnate slurry A for about 30 minutes...

example 2

[0027] Step 1: Preparation of composite material preform: Clean the C / SiC composite material preform with an open porosity of 30vol%-40vol% with ultrasonic waves for at least 30 minutes, and dry it in an oven at 80℃-100℃ for later use.

[0028] Step 2: Slurry preparation: Add ZrC powder to a 0.5%-1% mass fraction of sodium cellulose (CMC) aqueous solution and ball mill for more than 24 hours to prepare slurry A. Slurry B was prepared by dissolving polycarbosilane (PCS) in absolute alcohol. The viscosity of the above slurry is controlled by the content of anhydrous alcohol or aqueous solution to about 60 mPa·s, and the dispersibility is controlled by adjusting the pH value (greater than 11).

[0029]Step 3: Vacuum pressure impregnation: the C / SiC preform of step 1 is first vacuum impregnated with slurry A for about 30 minutes, then pressurized to 0.8MPa pressure by inert gas to impregnate slurry A for about 30 minutes and dry, repeat the impregnation and drying 3-4 times, a su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com