Preparation method of high temperature resistant ceramic matrix composite screw

A technology of high-temperature-resistant ceramics and composite materials, which is applied in the field of preparation of high-temperature-resistant ceramic-based composite screws, can solve the problems that the temperature resistance can only reach 1650 ° C, and the thread accuracy is reduced, so as to improve the mechanical properties and oxidation resistance. The effect of complete screw teeth and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

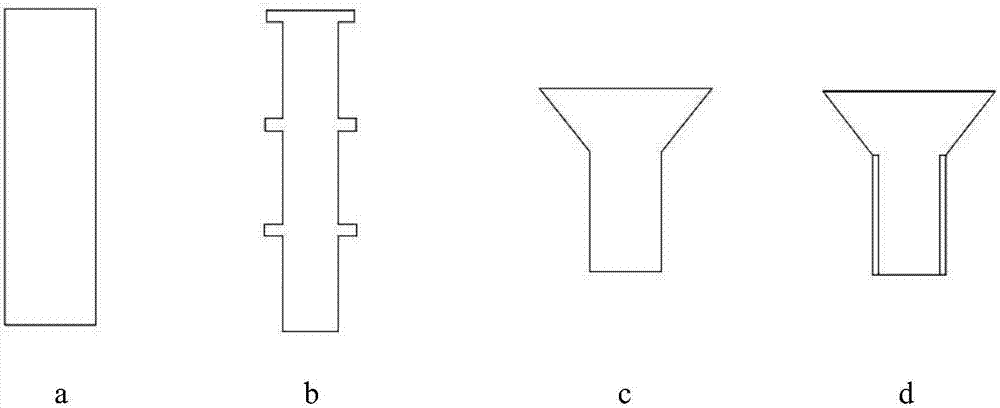

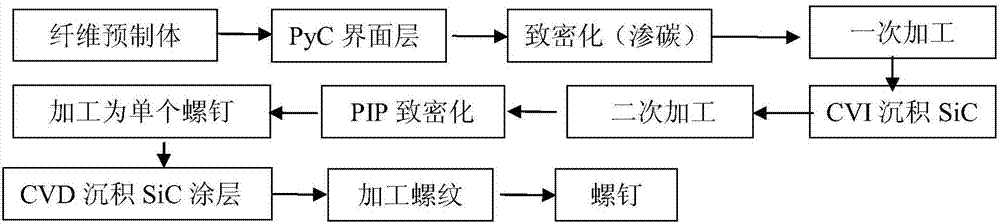

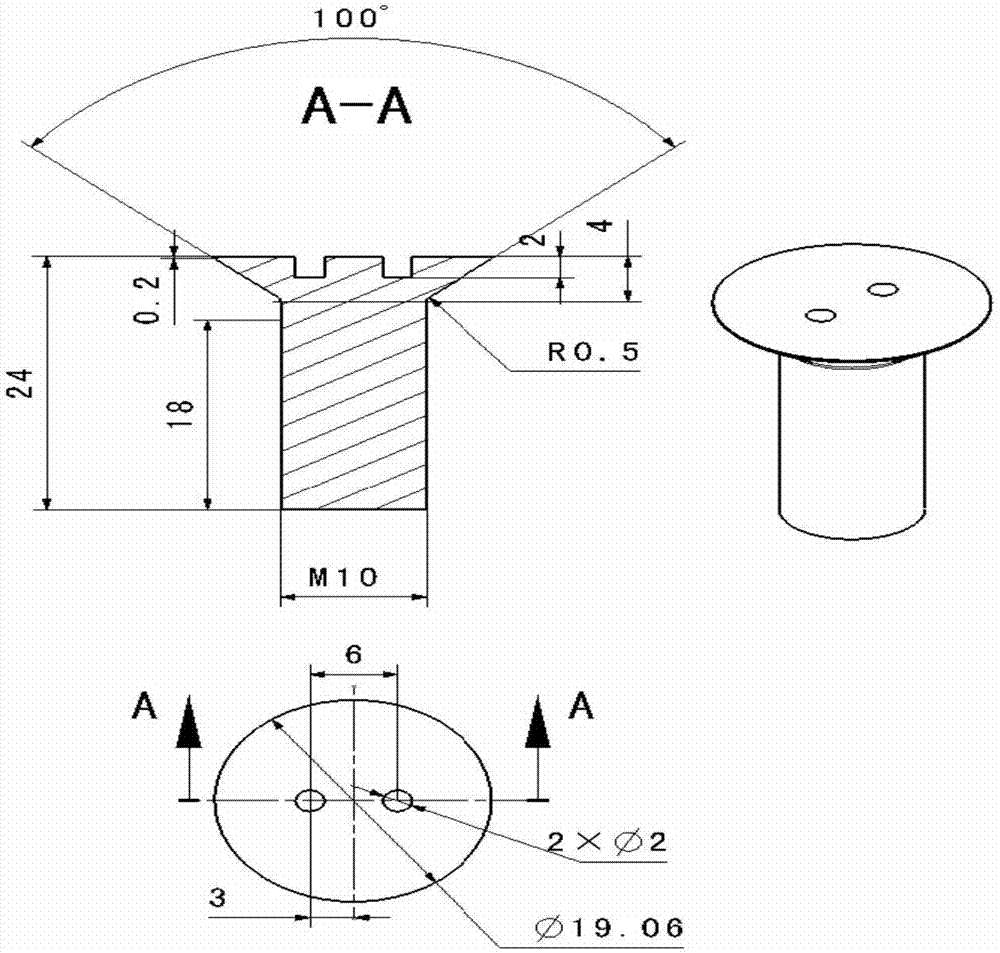

[0041] M10 metric coarse thread round head standard bolts. The total length of the bolt is 24mm, the height of the countersunk head is 4mm, the length of the screw rod is 20mm, the total length of the thread is 18mm, and the angle of the countersunk head is 100°.

[0042] Use T7006K carbon fiber non-weft cloth and T70012K mesh tire to alternately lay up and needle-punch carbon fiber prefabricated body, in which the non-weft cloth 0 / 90° lay-up, and mesh tire 1.X+1.Y are continuously needle-punched into a carbon fiber prefabricated flat plate, The density is controlled at 0.45-0.5g / cm 3 .

[0043] Place the prefabricated flat plate in a CVI furnace, use propane and argon as raw materials, control the flow ratio of the two to 1:3, deposit at 950°C for 48 hours, and the density reaches 1.0g / cm 3 , Take out the screw that is processed as continuous. The shank diameter is 12mm, the screw head diameter is 25mm, and the height is 10mm.

[0044] Put the processed continuous screw i...

Embodiment 2

[0049] M12 metric coarse thread hexagonal standard bolts. The total length of the bolt is 25mm, the bolt head is 5mm, the length of the screw rod is 20mm, and the total length of the thread is 18mm.

[0050] In the X and Y directions, T7006KPANCF continuous long-fiber soft braid is used to lay up the long-fiber layer at 0 / 90°, and the Z-direction is made of T7006KPANCF bidirectional puncture to make a carbon fiber prefabricated body with thin edges, and the density is controlled at 0.6-0.75g / cm 3 .

[0051] Put the preform in a CVI furnace, use propane and argon as raw materials, control the flow ratio of the two to 1:2.5, deposit at 1000°C for 36 hours, and the density reaches 1.20g / cm 3 , Take out the screw that is processed as continuous. The shank diameter is 15mm and the height of the screw head is 12mm.

[0052] Put the processed continuous screw into the CVI furnace, H 2 The / Ar flow ratio is 1:2, the MTS flow rate is 200g / h, the deposition temperature is 1300°C, th...

Embodiment 3

[0056] M8 metric coarse thread hexagonal standard bolts. The total length of the bolt is 25mm, the bolt head is 5mm, the length of the screw rod is 20mm, and the total length of the thread is 18mm.

[0057] Silicon carbide fiber prefabricated body is formed by alternate lamination of silicon carbide fiber cloth, in which the cloth is laminated at 0 / 90°, continuously needled into a flat plate of fiber prefabricated body, and the density is controlled at 0.75g / cm 3 .

[0058] Put the preform in a CVI furnace, use propane and argon as raw materials, control the flow ratio of the two to 1:2.5, deposit at 1100°C for 24 hours, and the density reaches 1.30g / cm 3 , Take out the screw that is processed as continuous. The shank diameter is 10mm and the height of the screw head is 12mm.

[0059] Put the processed continuous screw into the CVI furnace, H 2 The / Ar flow ratio is 1:2, the MTS flow rate is 250g / h, the deposition temperature is 1500°C, the deposition time is 80 hours, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com