Preparation method of high-density ultra-high-temperature Ta4HfC5 ceramic block material

A dense and ceramic block technology, which is applied in the field of preparation of high-density and ultra-high temperature Ta4HfC5 ceramic blocks, can solve various problems such as poor performance, high cost, and low block density, and achieve high density and reduce oxidation. , excellent physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: Apply the method provided by the present invention to prepare a kind of high-density ultra-high temperature Ta 4 HfC 5 Ceramic blocks, the specific steps are as follows:

[0022] The first step, choose TaSi 2 As a flux, TaSi 2 The added amount is 6vol.% volume fraction, Ta 4 HfC 5 The volume of the solid solution powder is 94vol.%. According to the volume ratio, the two original powders are mixed.

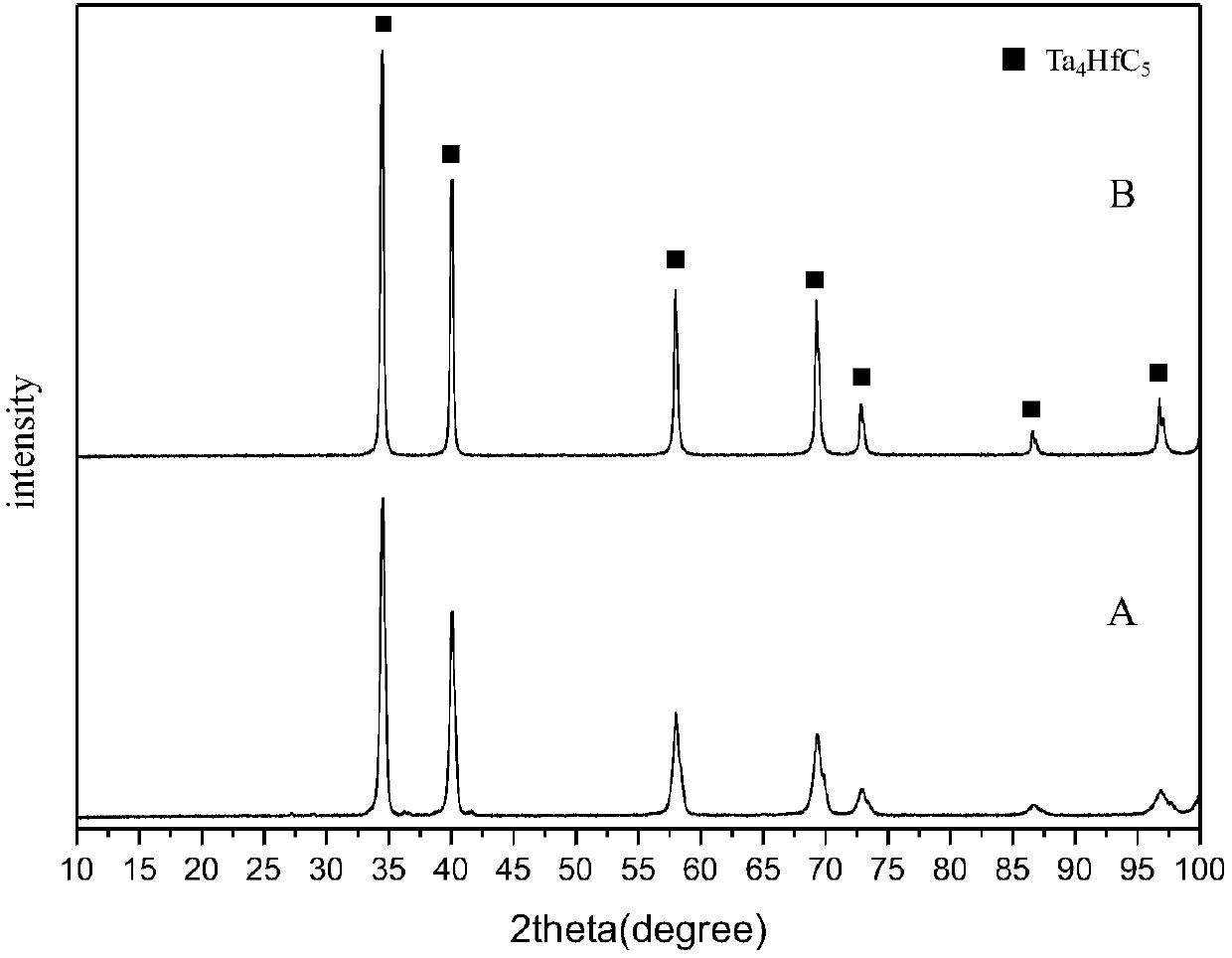

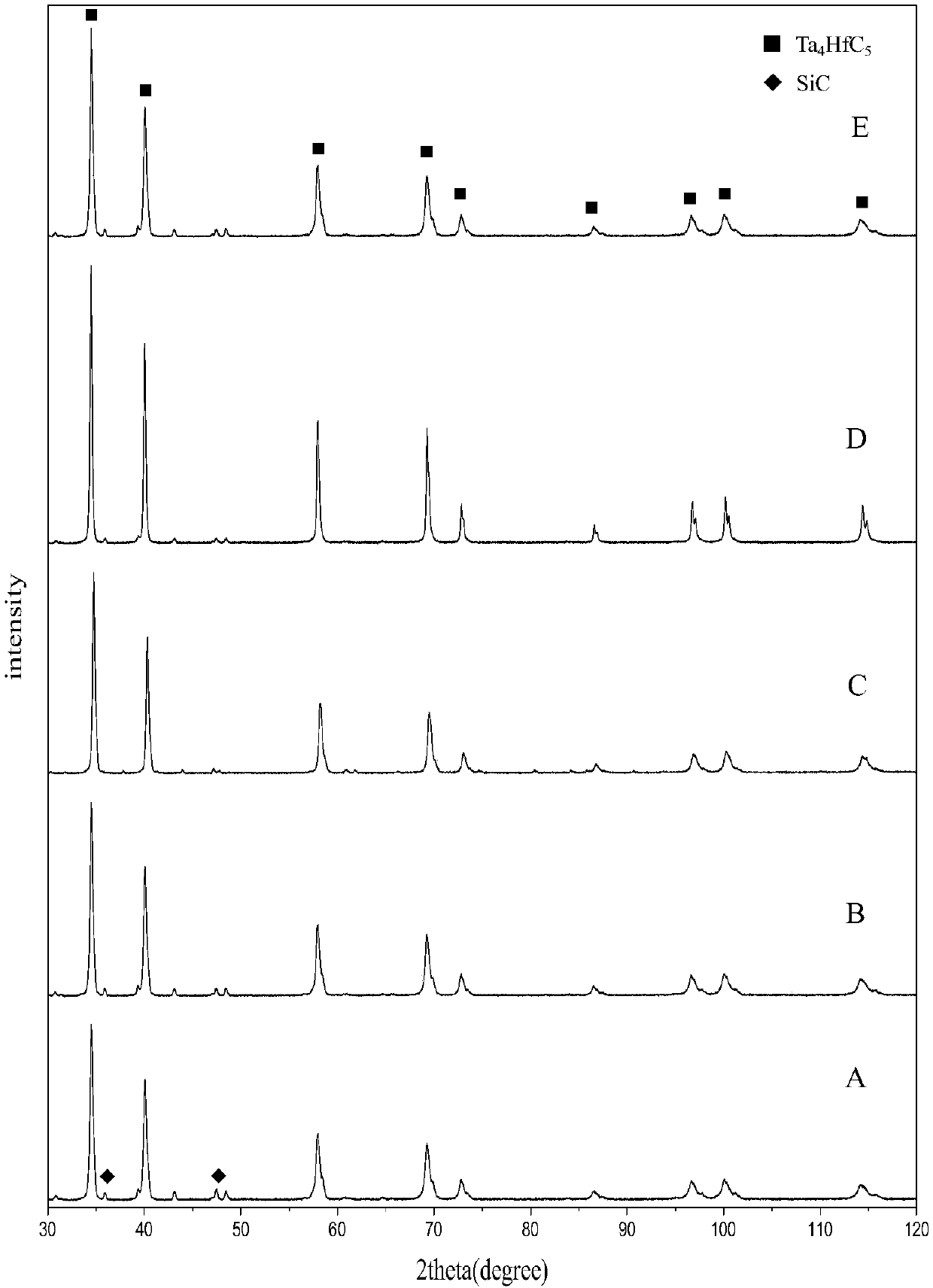

[0023] Such as figure 1 Curve A shown is the use of X-ray diffractometer to analyze Ta 4 HfC 5 solid solution powder, showing only Ta 4 HfC 5 Crystal phase, indicating that the powder is Ta 4 HfC 5 solid solution.

[0024] In the second step, the mixed powder of the first step is subjected to high-energy ball milling, the ball milling speed is 300r / min, and high-purity Ar gas is used as the protective atmosphere, the ball milling time is 15 hours, and the powder obtained by ball milling is analyzed using a laser particle size analyzer. The D50 of t...

Embodiment 2

[0028] The first step, choose TaSi 2 As a flux, TaSi 2 The added amount is a volume fraction of 12vol%, Ta 4 HfC 5 The volume of the powder is 88vol.%. According to the volume ratio, the two original powders are mixed.

[0029]The second step is to carry out high-energy ball milling after the powder is mixed. The ball milling speed is 200r / min, and high-purity Ar gas is used as the protective atmosphere. The ball milling time is 20 hours. The powder obtained by ball milling is analyzed by a laser particle size analyzer to obtain a powder. The D50 was 1.49 μm, and 3.0 g of mixed powder was weighed.

[0030] The third step is to dry the mixed powder and put it into the SPS graphite mold with a diameter of 10mm. After vacuuming, apply DC pulse current heating to the graphite mold in a vacuum state. The heating rate is 100°C / min. From Start to pressurize at room temperature, slowly pressurize to the preset pressure of 30MPa, and keep the pressure until the sintering is complet...

Embodiment 3

[0033] The first step, choose TaSi 2 As a flux, TaSi 2 The added amount is a volume fraction of 12vol%, Ta 4 HfC 5 The volume of the powder is 88vol%. According to the volume ratio, the two original powders are mixed.

[0034] In the second step, the mixed powder is subjected to high-energy ball milling, the ball milling speed is 300r / min, and high-purity Ar gas is used as the protective atmosphere, and the ball milling time is 5 hours. The particle size analysis of the powder obtained by ball milling is obtained by using a laser particle size analyzer. The D50 of the powder was 1.49 μm, and 3.0 g of the mixed powder was weighed.

[0035] The third step is to dry the mixed powder and put it into the SPS graphite mold with a diameter of 10mm. After vacuuming, apply DC pulse current heating to the graphite mold in a vacuum state. The heating rate is 100°C / min. From Start to pressurize at room temperature, slowly pressurize to the preset pressure of 30MPa, and keep the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com