Circular saw tool bit laser machining equipment and circular saw tool bit laser machining method

A technology of laser processing and circular sawing, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of low efficiency, achieve reliable processing and improve processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the technical content and structural features of the present invention in detail, further description will be given below in conjunction with the implementation and accompanying drawings.

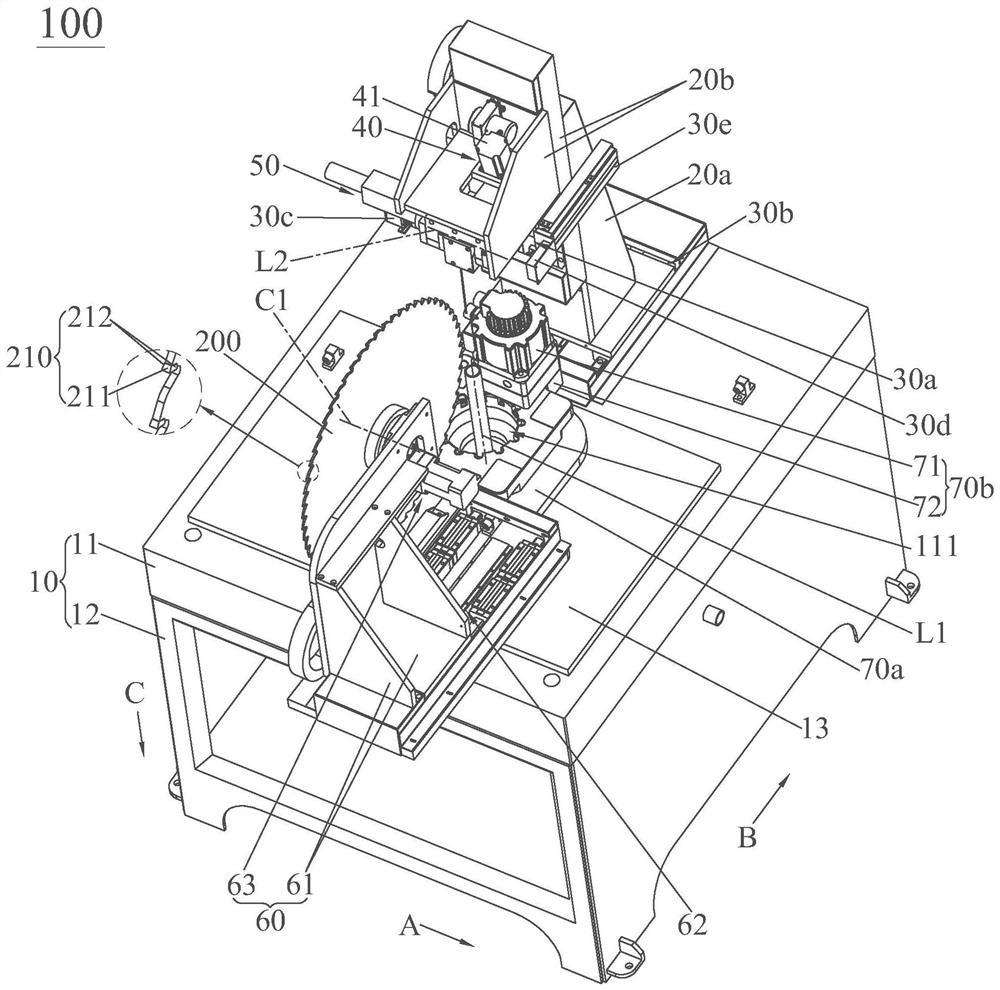

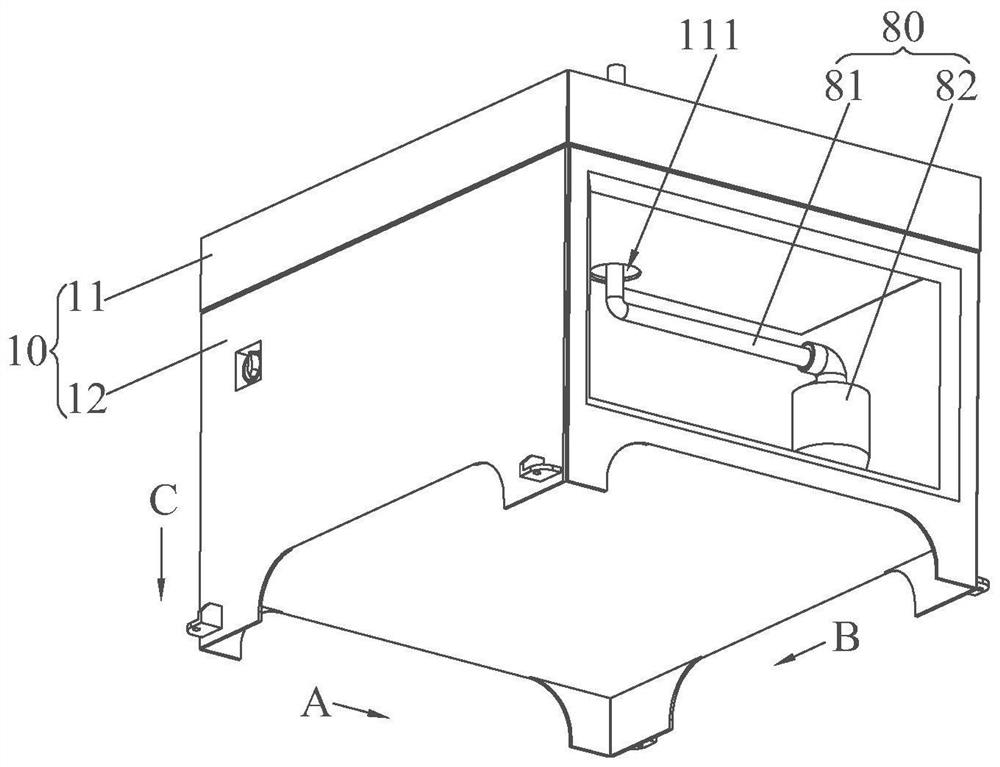

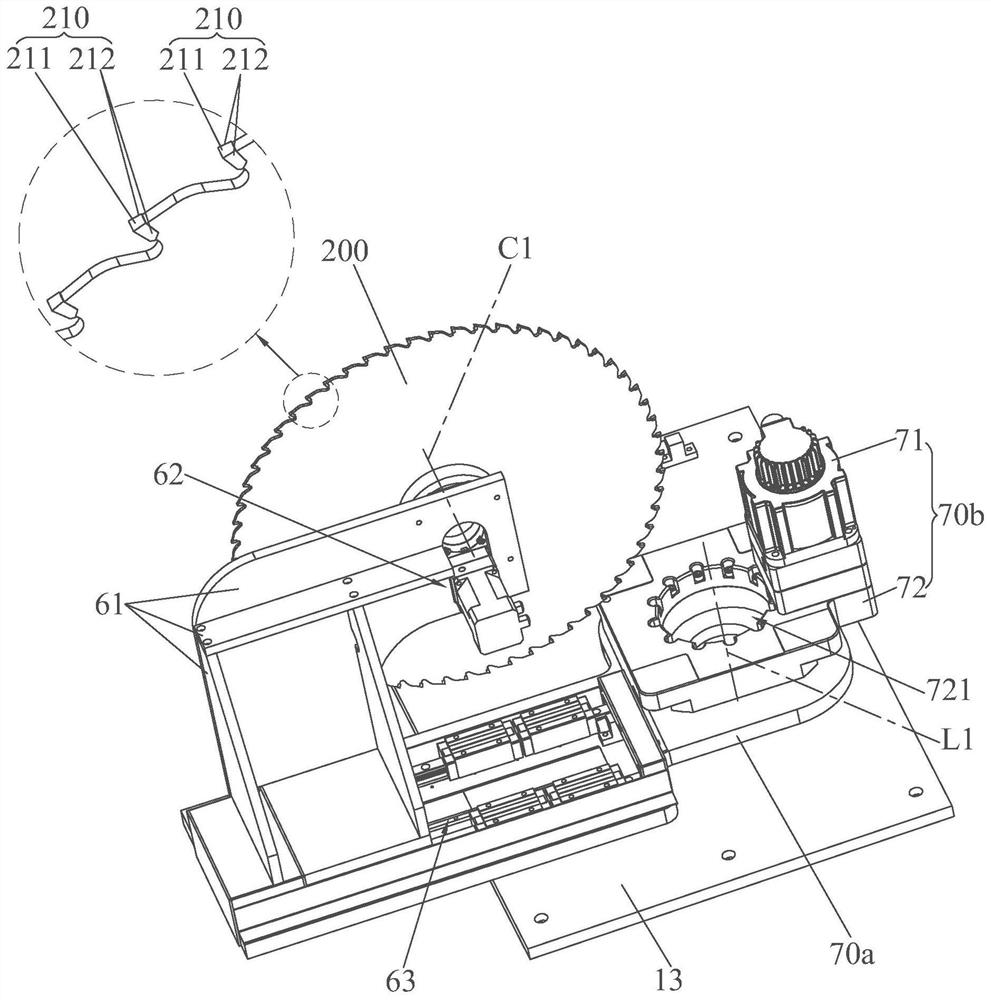

[0036] see figure 1 , the circular saw cutter head laser processing equipment 100 of the first embodiment of the present invention is suitable for performing laser processing on the cutter face (such as the flank face 211 and both sides of the cutter face 212) of the cutter head 210 in the circular saw 200, so as to realize the The laser machining of the blade face of the blade head 210 in the saw 200 is required. Wherein, the laser processing equipment 100 of the circular saw cutter head according to the first embodiment of the present invention includes a frame 10, a sliding stand 20a, a lifting slide 20b, a lifting driving mechanism 30a, a sliding driving mechanism 30b, an angle adjusting mechanism 40, a leather Second laser 50 and hanging knife mechanism 60....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com