Preparation method of carbon fiber-reinforced ultra high-temperature ceramic-base composite material capable of being repeatedly ablated for use

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of preparation of carbon fiber reinforced ultra-high temperature ceramic matrix composite materials, can solve the problems of difficult to withstand repeated ablation, lack of protective layer, and volatile loss of protective layer, etc. protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

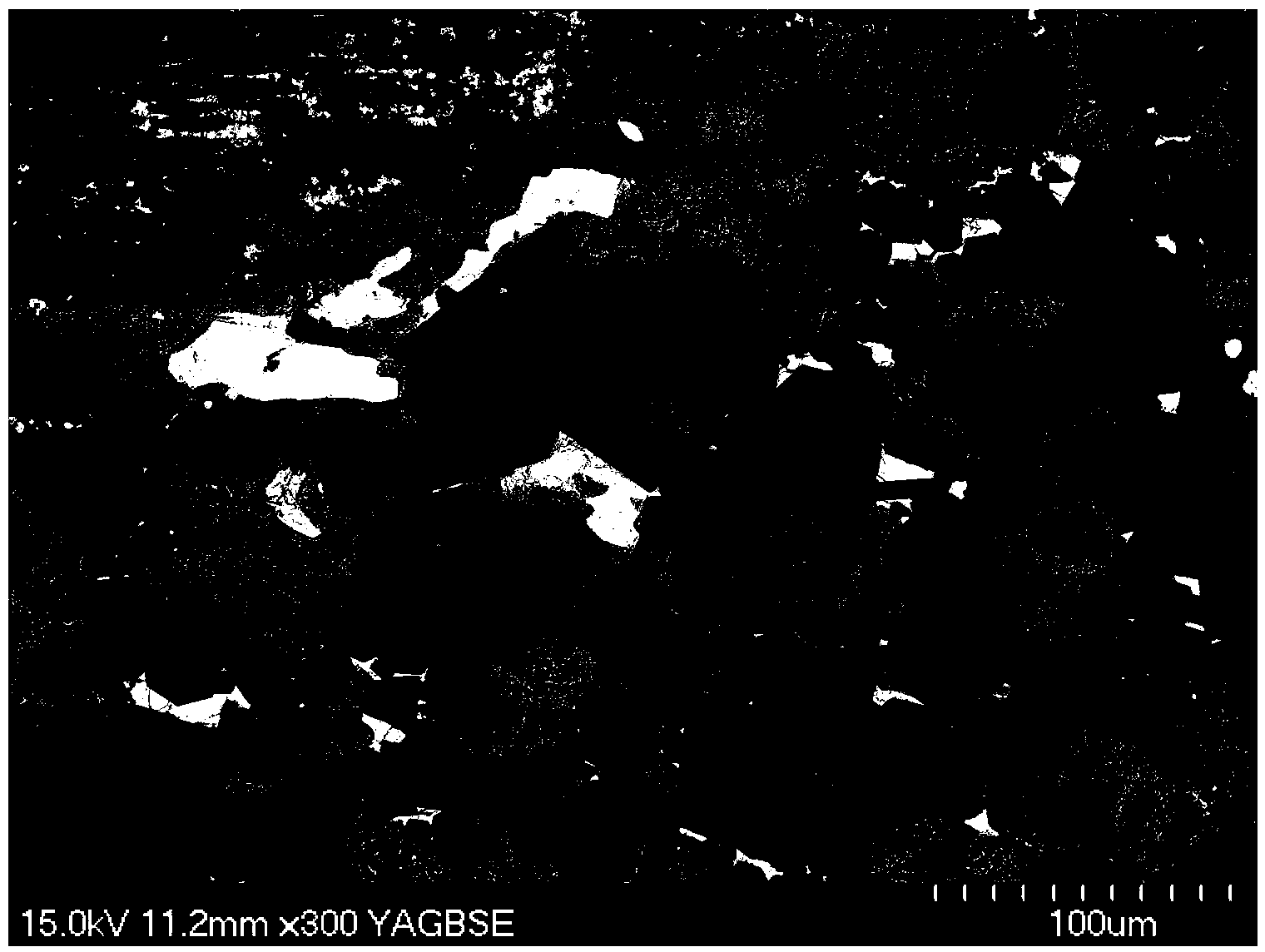

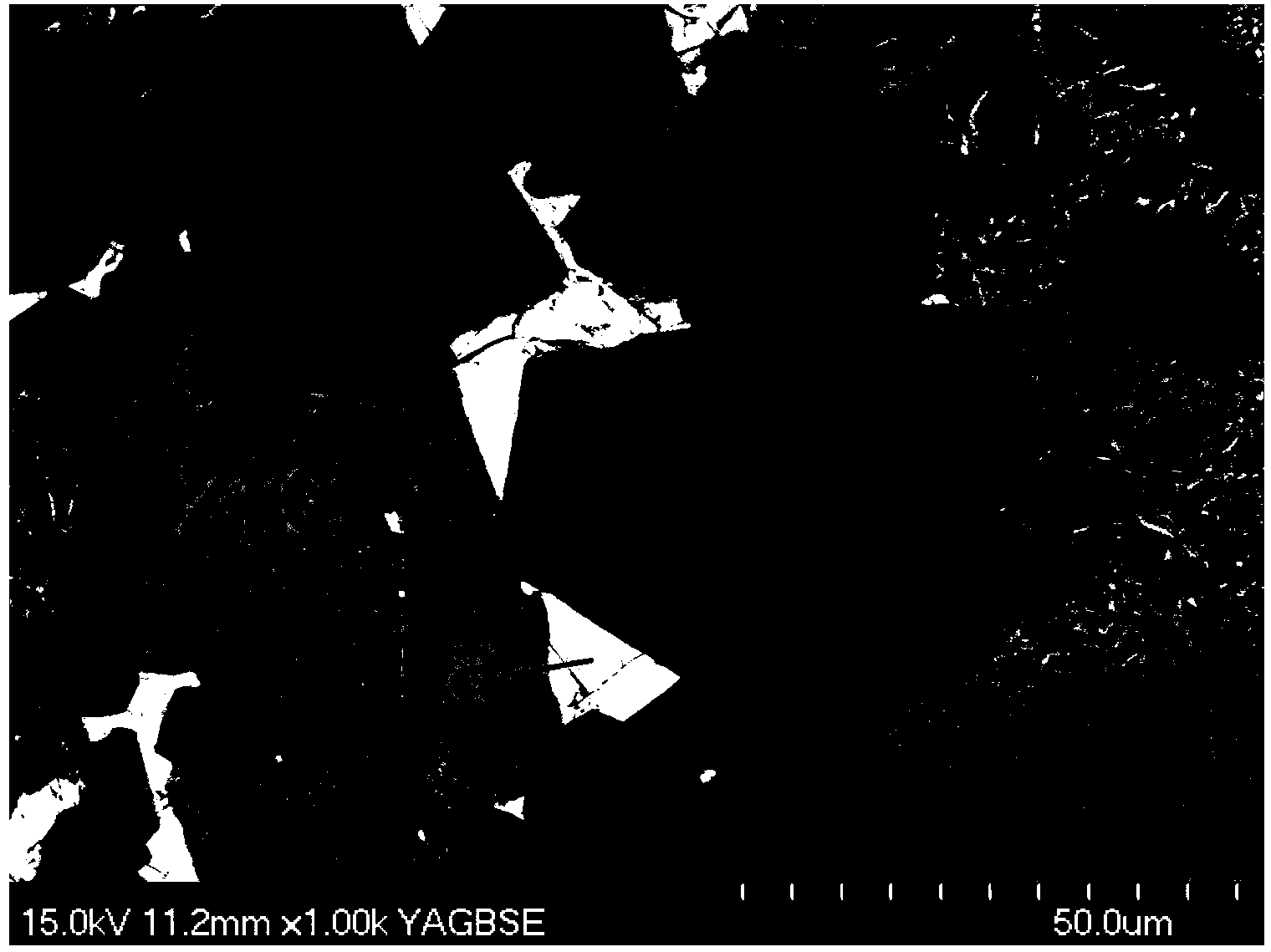

Image

Examples

Embodiment 1

[0025] Preparation of composite material preform: CVI process is used to pyrolyze propylene at 960°C to deposit a pyrolytic carbon interface phase on the surface of carbon fibers, and MTS is loaded into a deposition furnace using hydrogen gas, and MTS is cracked at 1000°C under a pressure of 5KPa to deposit SiC For the matrix, a C / SiC composite material preform with an open porosity of 20vol% was cleaned by ultrasonic cleaning for at least 30 minutes, and dried in an oven at 80° C. to obtain a clean and dry preform.

[0026] Slurry preparation: Dissolve phenolic resin and hexamethylenetetramine in absolute ethanol, then add La(NO 3 ) 3 ·xH 2 O and ball milled for more than 24 hours to obtain the slurry; the ratio of phenolic resin and nitrate is 1:3, and the quality of hexamethylenetetramine is 0.1 times of the quality of the phenolic resin; the viscosity of the slurry is controlled by the content of absolute ethanol to be 50~ 100mPa·s.

[0027] Vacuum pressure impregnation...

Embodiment 2

[0031] Preparation of composite material preform: CVI process is used to pyrolyze propylene at 960°C to deposit a pyrolytic carbon interface phase on the surface of carbon fibers, and MTS is loaded into a deposition furnace using hydrogen gas, and MTS is cracked at 1000°C under a pressure of 5KPa to deposit SiC The matrix, the obtained C / SiC composite preform with an open porosity of 20vol%, was cleaned by ultrasonic waves for at least 30 minutes, and dried in an oven at 80°C to obtain a clean and dry preform.

[0032] Slurry preparation: La 2 o 3 The powder was added to 0.5% cellulose sodium CMC aqueous solution and ball milled for more than 24 hours, La 2 o 3 Mass fraction is 30%, obtains slurry a; Phenolic resin, hexamethylenetetramine are dissolved in dehydrated alcohol, obtain slurry b, hexamethylenetetramine quality is 0.1 times of phenolic resin quality, pass through The content of water ethanol controls the viscosity of the slurry to be 50-100 mPa·s.

[0033] Vacuu...

Embodiment 3

[0037] Preparation of composite material prefabricated body: In the carbon fiber prefabricated body, the phenolic resin slurry is pressure-impregnated, the vacuum degree is -0.08MPa, the pressure is 0.8MPa, and the resin is cracked at 900°C after curing at 150°C to obtain an open porosity of 30vol%. The C / C composite material preform was cleaned by ultrasonic waves for at least 30 minutes, and dried in an oven at 80° C. to obtain a clean and dry preform.

[0038] Slurry preparation: dissolve furan resin and hexamethylenetetramine in absolute ethanol, then add Y(NO 3 ) 3 ·xH 2 O and ball milled for more than 24 hours to obtain the slurry; the ratio of furan resin and nitrate is 1:4, and the quality of hexamethylenetetramine is 0.1 times of the quality of furan resin; the viscosity of the slurry is controlled by the content of absolute ethanol to be 50~ 100mPa·s.

[0039] Vacuum pressure impregnation: Put the C / C preform and the slurry into the vacuum tank at the same time, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com