Cf/C-MC ultra-high-temperature ceramic matrix composite and preparation method thereof

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of Cf/C-MC ultra-high temperature ceramic matrix composite materials and its preparation, can solve the problems of reduced mechanical properties of materials, long production cycle, carbon fiber damage, etc., and achieves low cost and synthesis. Faster and more efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

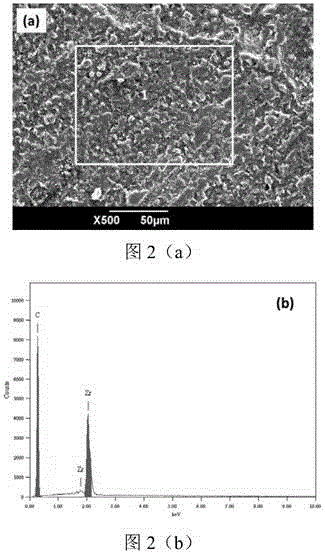

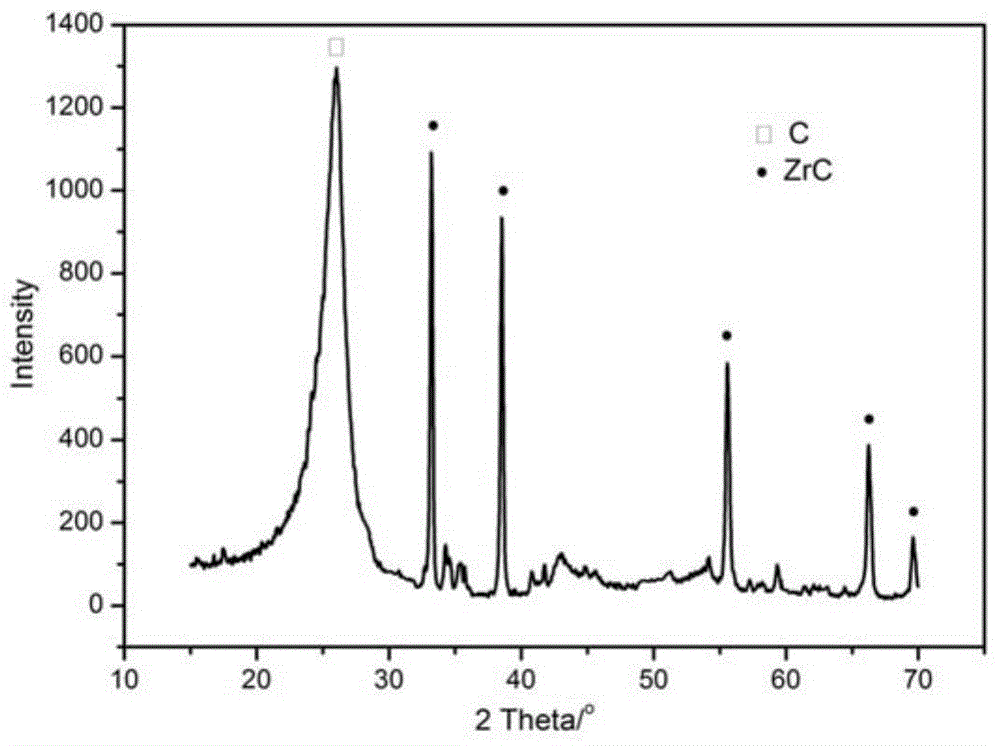

[0025] A preparation method of Cf / C-MC (M=Zr) ultra-high temperature ceramic matrix composite material, comprising the following steps:

[0026] 1) Chopped carbon felt is selected as the carbon fiber preform; glucose is used as the carbon source, and glucose solution A with a concentration of 50 g / L is prepared;

[0027] 2) Choose chemically pure ZrOCl 2 ·8H 2 O was dissolved in deionized water and placed in a constant temperature magnetic stirrer at 50 °C to fully stir, and the pH value was adjusted to 4 with a NaOH solution with a mass concentration of 20%, to prepare Zr 4+ The concentration is 0.5mol / L solution B;

[0028] 3) Put the carbon source solution A into the reaction kettle, and put the carbon fiber prefabricated body, put the reaction kettle into the homogeneous reactor to carry out the synthesis reaction, the temperature of the hydrothermal reaction is 180°C, and the reaction time is 6h; After cooling to room temperature, the carbon fiber preform was taken out...

Embodiment 2

[0033] A preparation method of Cf / C-MC (M=Zr) ultra-high temperature ceramic matrix composite material, comprising the following steps:

[0034] 1) Chopped carbon felt is selected as the carbon fiber preform; sucrose is used as the carbon source, and a sucrose solution A with a concentration of 80 g / L is prepared;

[0035] 2) Choose chemically pure ZrCl 4 Dissolved in deionized water and placed in a constant temperature magnetic stirrer at 50 ° C to fully stir, adjust the pH value to 6 with a NaOH solution with a mass concentration of 20%, and prepare Zr 4+ The concentration is 1mol / L;

[0036] 3) Put the carbon source solution A into the reaction kettle, and put the carbon fiber prefabricated body, put the reaction kettle into the homogeneous reactor to carry out the synthesis reaction, the temperature of the hydrothermal reaction is 190°C, and the reaction time is 5h; After cooling to room temperature, the carbon fiber preform was taken out and dried at 80° C. for 4 hours ...

Embodiment 3

[0043] A preparation method of Cf / C-MC (M=Zr) ultra-high temperature ceramic matrix composite material, comprising the following steps:

[0044] 1) Chopped carbon cloth is selected as the carbon fiber preform; starch is used as the carbon source to prepare starch solution A with a concentration of 70g / L;

[0045] 2) Use chemically pure ZrO(NO 3 ) 2 2H 2 O was dissolved in deionized water and placed in a constant temperature magnetic stirrer at 50 ° C to fully stir, and the pH value was adjusted to 8 with a NaOH solution with a mass concentration of 20%, to prepare Zr 4+ The concentration is 1.5mol / L solution B;

[0046] 3) Put the carbon source solution A into the reaction kettle, and put the carbon fiber prefabricated body, put the reaction kettle into the homogeneous reactor to carry out the synthesis reaction, the temperature of the hydrothermal reaction is 200°C, and the reaction time is 4h; After cooling to room temperature, the carbon fiber preform was taken out and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com