Carbon fiber-reinforced (carbon-) silicon carbide base-ultra-high temperature ceramic base compound material and production method thereof

A technology of ultra-high temperature ceramics and composite materials, applied in the field of carbon fiber reinforced silicon carbide-ultra-high temperature ceramic matrix composite materials and its preparation, can solve the problem of low density, high mechanical properties, long-term anti-oxidation and ablation resistance, high density, Low mechanical properties and other problems, to achieve outstanding mechanical properties and meet the effect of ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

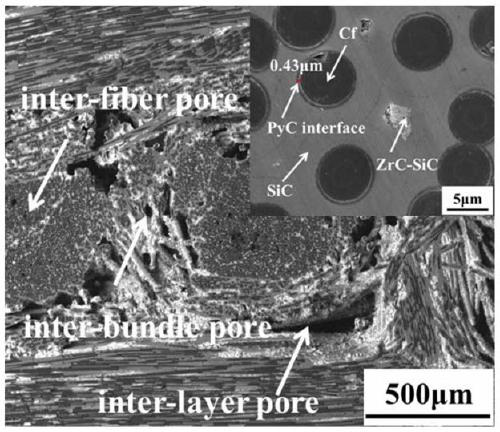

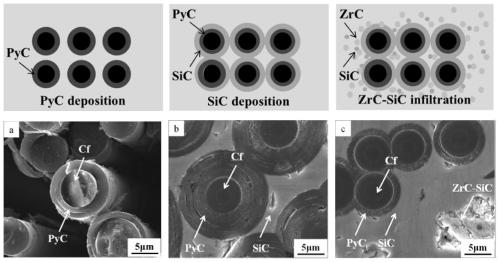

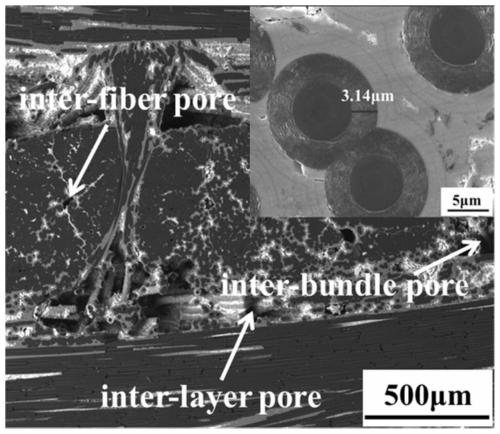

[0046] The grades are U~ZCS0.12 composite material preparation method and material properties:

[0047] Choose 380×80×10mm, the density is 0.5g / cm 3 The 2D needle-punched carbon fiber preform; the pyrolytic carbon interface layer was prepared by ICVI process, the temperature was 900°C, and the flow rate of argon gas was 0.1m 3 / h, propane 0.1m 3 / h, the deposition time is 5 hours; the deposition time of the PyC substrate in the PyC-SiC functional layer is 0h; the SiC substrate required for the PyC-SiC functional layer is prepared by the ICVI process, the temperature is 1000 ° C, hydrogen, argon and trichloromethylsilane , the volume ratio is 5:5:1, the deposition time is 500 hours, and the material density is 1.8g / cm 3 ;Using CNC machining and forming, ultrasonic cleaning; using PIP technology to introduce ZrC-SiC ultra-high temperature ceramic phase, after 7 cycles of impregnation and cracking, the specific process parameters are: vacuum degree 2000Pa, impregnation pressure...

Embodiment 2

[0049] The grade is U~ZCS0.91 composite material preparation method and material properties:

[0050] Choose 380×80×10mm, the density is 0.5g / cm 3 The 2D needle-punched carbon fiber preform; the pyrolytic carbon interface layer was prepared by ICVI process, the temperature was 900°C, and the flow rate of argon gas was 0.1m 3 / h, propane 0.1m 3 / h, the deposition time is 5 hours; use the ICVI process to prepare the PyC substrate required for the PyC-SiC functional layer, the temperature is 950 ° C, and the flow rate of argon gas is 0.15m 3 / h, propane 0.15m 3 / h, the deposition time is 200 hours; use the ICVI process to prepare the SiC substrate required for the PyC-SiC functional layer, the temperature is 1000 ° C, hydrogen, argon and trichloromethylsilane, the volume ratio is 5:5:1, and the deposition time is 300 hours , material density 1.65g / cm 3 ; The SiC substrate required for the SiC anti-oxidation layer was prepared by the ICVI process, the temperature was 1050°C, t...

Embodiment 3

[0052] The grade is U~ZCS3.28 composite material preparation method and material properties:

[0053] Choose 380×80×10mm, the density is 0.5g / cm 3 The 2D needle-punched carbon fiber preform; the pyrolytic carbon interface layer was prepared by ICVI process, the temperature was 900°C, and the flow rate of argon gas was 0.1m 3 / h, propane 0.1m 3 / h, the deposition time is 5 hours; use the ICVI process to prepare the PyC substrate required for the PyC-SiC functional layer, the temperature is 950 ° C, and the flow rate of argon gas is 0.15m 3 / h, propane 0.15m 3 / h, the deposition time is 400 hours; use the ICVI process to prepare the SiC substrate required for the PyC-SiC functional layer, the temperature is 1000 ° C, hydrogen, argon and trichloromethylsilane, the volume ratio is 5:5:1, and the deposition time is 200 hours , material density 1.8g / cm 3 ;Using CNC machining and forming, ultrasonic cleaning; using PIP technology to introduce ZrC ultra-high temperature ceramic ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com