Zirconium-aluminum-silicon-carbon-silicon carbide composite material and preparation method thereof

A composite material, zirconium-aluminum-silicon-carbon matrix technology, applied in the field of in-situ reaction hot pressing to prepare zirconium-aluminum-silicon-carbon-silicon carbide composite materials, zirconium-aluminum-silicon-carbon-silicon carbide] 4C5-SiC) composite materials, can solve the problem of hardness , Low strength and toughness, limiting wide application and other issues, to achieve the effect of high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The raw materials are 100.0 grams of Zr powder, 53.5 grams of Al powder, 19.5 grams of Si powder and 35.6 grams of C powder with a particle size of about 350 mesh. They are ball milled in an alcohol medium for 10 hours, and cold pressed into a cake under a pressure of 10 MPa. In 20 minutes, put it into a graphite mold, and heat it up to 1850° C. in situ reaction hot pressing for 1 hour in a hot pressing furnace with an inert gas (argon) as a protective gas at a rate of 5 ° C / min. The hot pressing pressure is 40MPa. Get Zr 3 [Al(Si)] 4 C 6 -10vol.% SiC composite material, the silicon carbide particle reinforcement phase is uniformly dispersed in the zirconium aluminum silicon carbon matrix, and the size of the zirconium aluminum silicon carbon-silicon carbide composite material is Φ50mm×24mm.

Embodiment 2

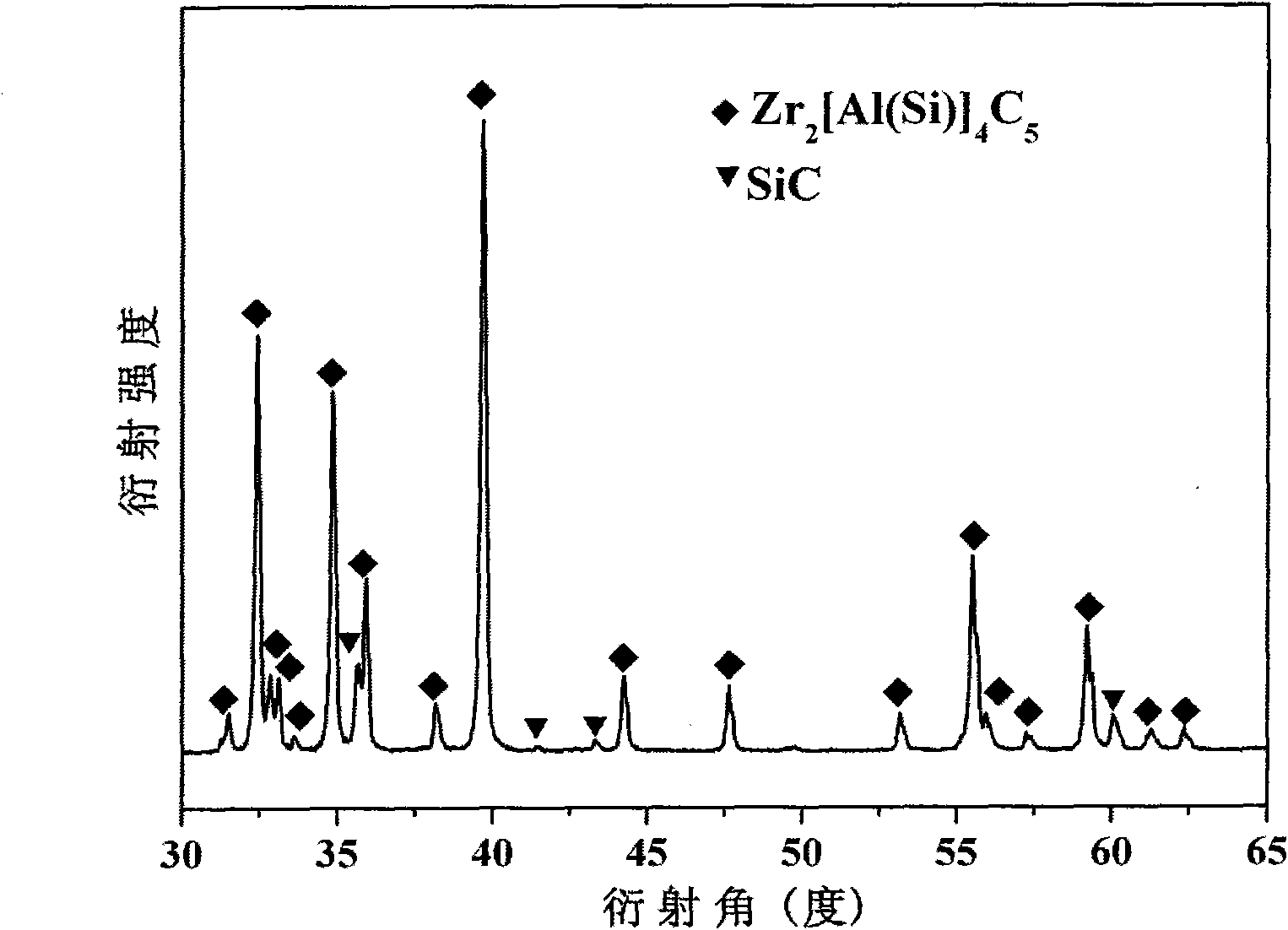

[0024] The raw materials are 100.0 grams of Zr powder, 54.3 grams of Al powder, 30.2 grams of Si powder and 42.6 grams of C powder with a particle size of about 300 meshes. They are ball-milled in an alcoholic medium for 10 hours and cold-pressed into cakes under a pressure of 15 MPa. 10 minutes, put it into a graphite mold, and heat it up to 2000° C. in situ reaction hot pressing for 1 hour in a hot pressing furnace with an inert gas (argon) as a protective gas at a rate of 10 ° C / min. The hot pressing pressure is 30MPa. Get Zr 3 [Al(Si)] 4 C 6 -20vol.% SiC composite material, the silicon carbide particle reinforcement phase is uniformly dispersed in the zirconium aluminum silicon carbon matrix, and the size of the zirconium aluminum silicon carbon-silicon carbide composite material is Φ60mm×18.8mm. The corresponding X-ray diffraction patterns are listed in the attached figure 1 superior.

Embodiment 3

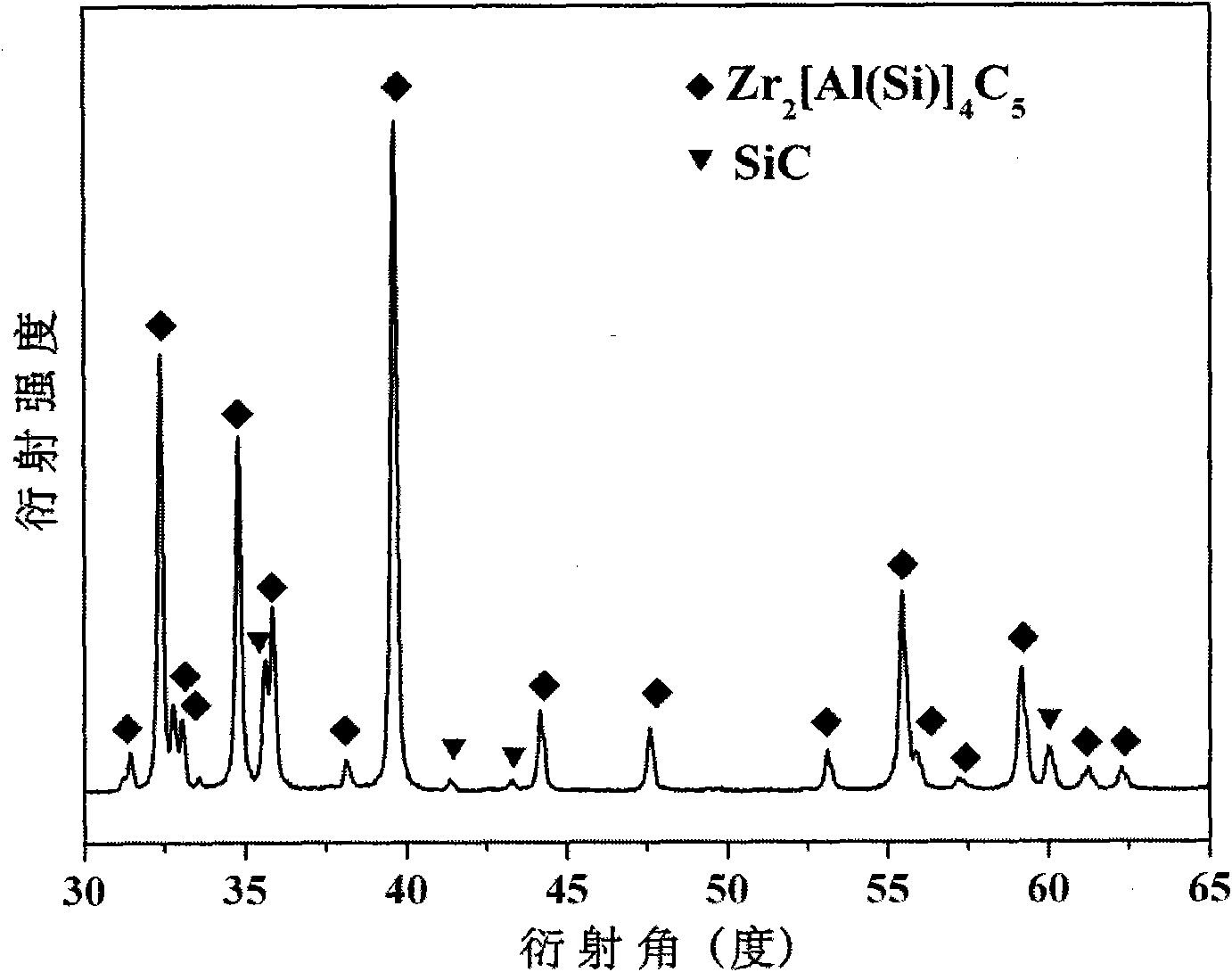

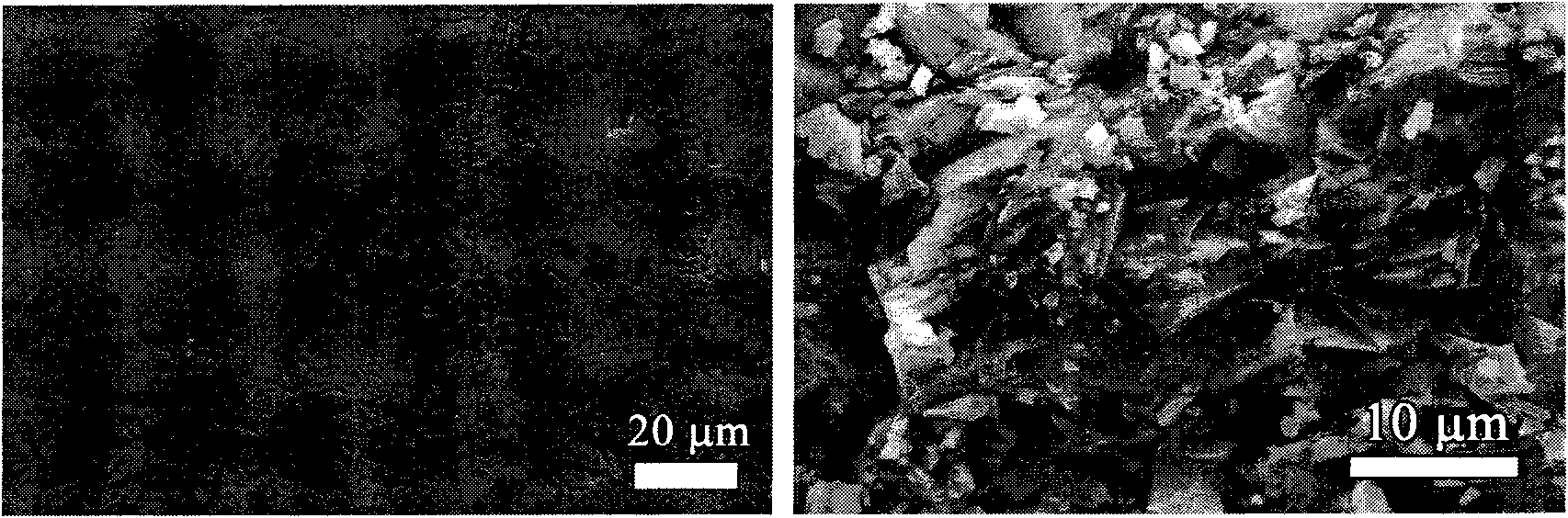

[0026] The raw materials are 100.0 grams of Zr powder, 52.1 grams of Al powder, 50.3 grams of Si powder and 47.8 grams of C powder with a particle size of about 400 meshes. They are ball milled in an alcohol medium for 15 hours, and cold pressed into a cake under a pressure of 20 MPa. 5 minutes, pack into graphite mold, under vacuum (vacuum degree is 10 -2 Pa) in a hot-pressing furnace at a rate of 15° C. / min to 1900° C. for in-situ reaction hot-pressing for 0.5 hour, and the hot-pressing pressure is 35 MPa. Get Zr 3 [Al(Si)] 4 C 6 -30vol.% SiC composite material, the silicon carbide particle reinforcement phase is uniformly dispersed in the zirconium aluminum silicon carbon matrix, and the size of the zirconium aluminum silicon carbon-silicon carbide composite material is Φ70mm×15.8mm. Corresponding X-ray diffraction patterns, crystal grain morphology scanning electron microscope photo, are listed in appendix respectively Figure 2-3 superior. The dynamic Young's modulus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com