Fiber-reinforced ceramic matrix composite material with ablation resistance, thermal shock resistance, high temperature and oxidation resistance coating and preparation method thereof

A high-temperature anti-oxidation and composite material technology, which is applied in the coating process of metal materials, ceramic layered products, chemical instruments and methods, etc.

Active Publication Date: 2014-01-15

SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

View PDF1 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In order to overcome the shortcomings of the existing method of improving the bonding strength of the coating and the composite material substrate, improving the thermal shock resistance of the coating, and overcoming the shortcomings of the multi-layer coating prepared by the prior art, the present invention proposes a fiber-reinforced ceramic matrix composite Abrasion-resistant, thermal-shock-resistant, high-temperature, and oxidation-resistant coating on the surface of the material, and a preparation method for the coating

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

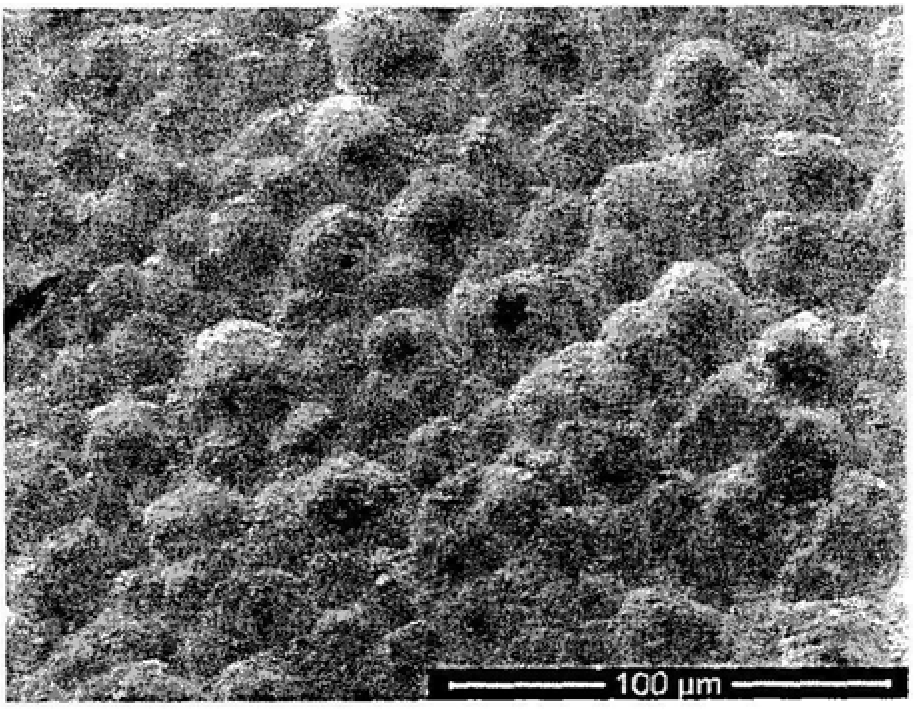

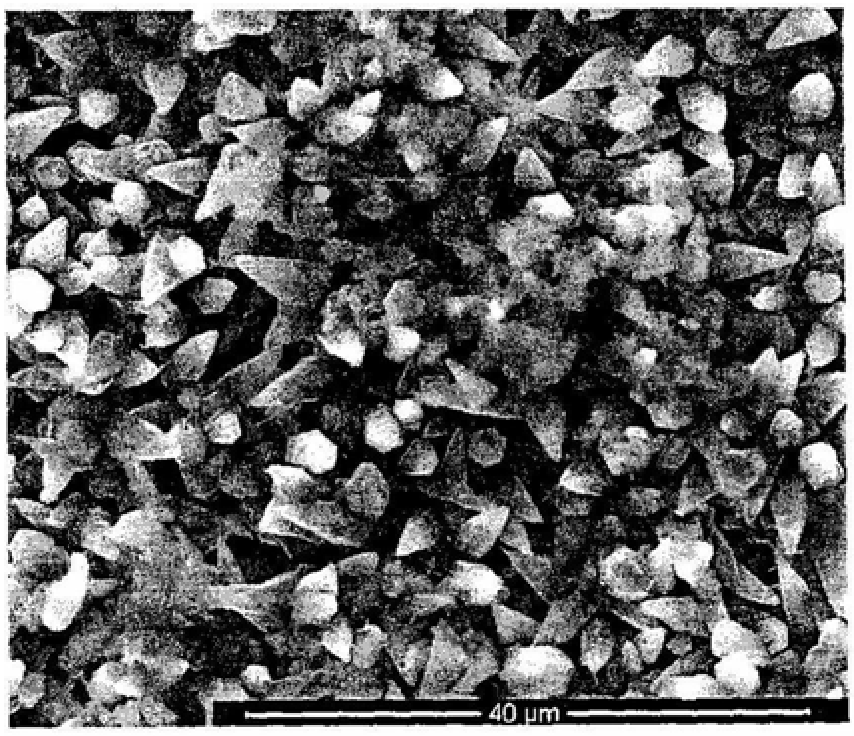

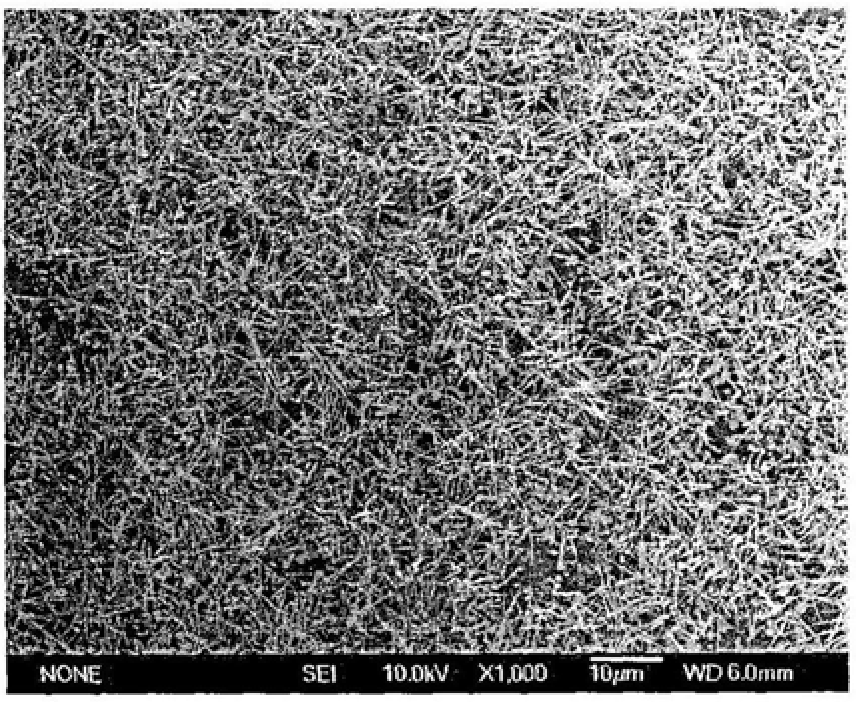

The invention proposes a high-temperature anti-oxidation coating on ablation-resistant and thermal-shock-resistant fiber-reinforced ceramic matrix composites, which is characterized in that the coating is formed by CVI- SiC coating formed by CVD process after SiC reinforcement layer; or using CVD process to alternately deposit one or two ultra-high temperature ceramic layers and SiC layers in MC or MB2 on the basis of using the aforementioned SiC coating as a transition layer The formed (MC / SiC)n or (MB2 / SiC)n or (MC / MB2 / SiC)n multilayer ultra-high temperature oxidation resistant coating, 1≤n≤100, the SiC layer in the multilayer ultra-high temperature oxidation resistant coating SiC nanowires and / or SiC whiskers are formed on the surface by in-situ growth through CVD process. In addition, the invention also proposes a preparation method of the high-temperature anti-oxidation coating. The invention can be widely used in the preparation of ablation-resistant, thermal shock-resistant, high-temperature and oxidation-resistant coatings on the surface of thermal structural parts.

Description

Fiber-reinforced ceramic matrix composite material with ablation resistance, thermal shock resistance, high temperature and oxidation resistance coating and preparation method thereof technical field The invention belongs to the field of composite materials, and in particular relates to an ablation-resistant, thermal-shock-resistant, high-temperature and oxidation-resistant coating for a fiber-reinforced ceramic matrix composite material; in addition, the invention also relates to a preparation method thereof. Background technique Fiber-reinforced ceramic matrix composites (including C / C composites) are promising high-temperature thermal structural materials due to their low density, high strength, and good high-temperature stability, and have been widely used in aerospace and other fields. prospect. However, in an oxidizing atmosphere, carbon fibers begin to oxidize above 400 °C, resulting in reduced performance or even failure of the composite material. At the same time...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B32B18/00C23C16/32C23C16/38

Inventor 董绍明张翔宇高乐王震何平周海军丁玉生

Owner SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com