Preparation method of in-plane isotropic zirconium boride-based ultra-high temperature monolithic structure ceramic with high damage tolerance

A damage-tolerant and isotropic technology, applied in the direction of inorganic raw material artificial filament, can solve the problem of poor damage tolerance, and achieve the effect of improving damage tolerance, breaking work, and critical crack size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

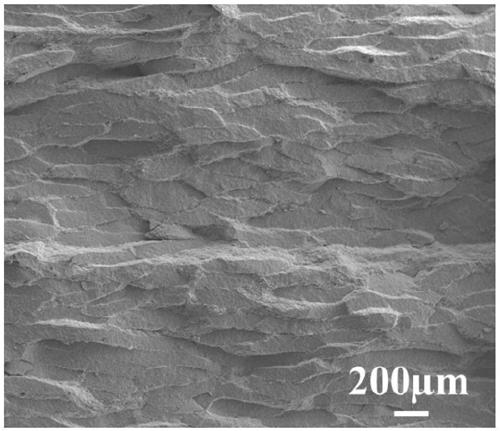

[0031] Specific Embodiment 1: In this embodiment, the method for preparing in-plane isotropic zirconium boride-based ultra-high temperature monolithic structure ceramics with high damage tolerance is carried out according to the following steps:

[0032] 1. Dissolving polyethersulfone in N-methylpyrrolidone to obtain solution A;

[0033] The mass ratio of polyethersulfone to N-methylpyrrolidone is 1: (9-11);

[0034] 2. Weighing ZrB 2 Powder and SiC powder, ZrB to be weighed 2 The powder, SiC powder and solution A are placed in a ball mill for ball milling and mixing to obtain ZrB 2 - SiC paste;

[0035] The ZrB 2 The volume ratio of the total volume of the powder and SiC powder to the solution A is (0.8-1.2): 3;

[0036] The ZrB 2 The volume ratio of powder and SiC powder is (75~85):20;

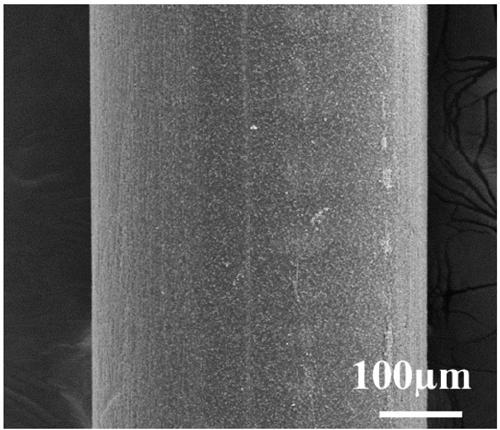

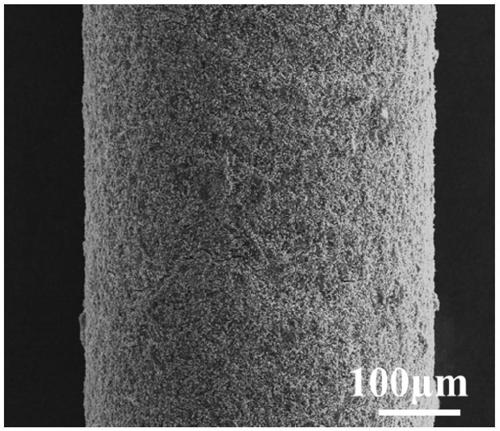

[0037] Three, the ZrB 2 -SiC slurry is transferred to the syringe of the syringe pump, and the syringe pump is started to transfer the ZrB 2 - SiC slurry extruded into water bath to g...

specific Embodiment approach 2

[0048] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in the process of dissolving polyethersulfone in step 1 in N-methylpyrrolidone, mechanical stirring is used, the stirring speed is 90-110r / min, and the stirring time is 43-53h . Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0049] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the purity of polyethersulfone in step 1 is ≥98%; the purity of N-methylpyrrolidone is 99wt.%. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com