Method for preparing Cf/ZrC-SiC superhigh-temperature ceramic composite material through hot-pressing sintering/precursor cracking process

A technology for cracking ultra-high temperature ceramics and precursors, which is applied in the field of preparing Cf/ZrC-SiC ultra-high temperature ceramic composite materials by hot pressing sintering/precursor cracking method, which can solve the problem of high manufacturing cost, long preparation cycle and unsuitable for thick-walled parts And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

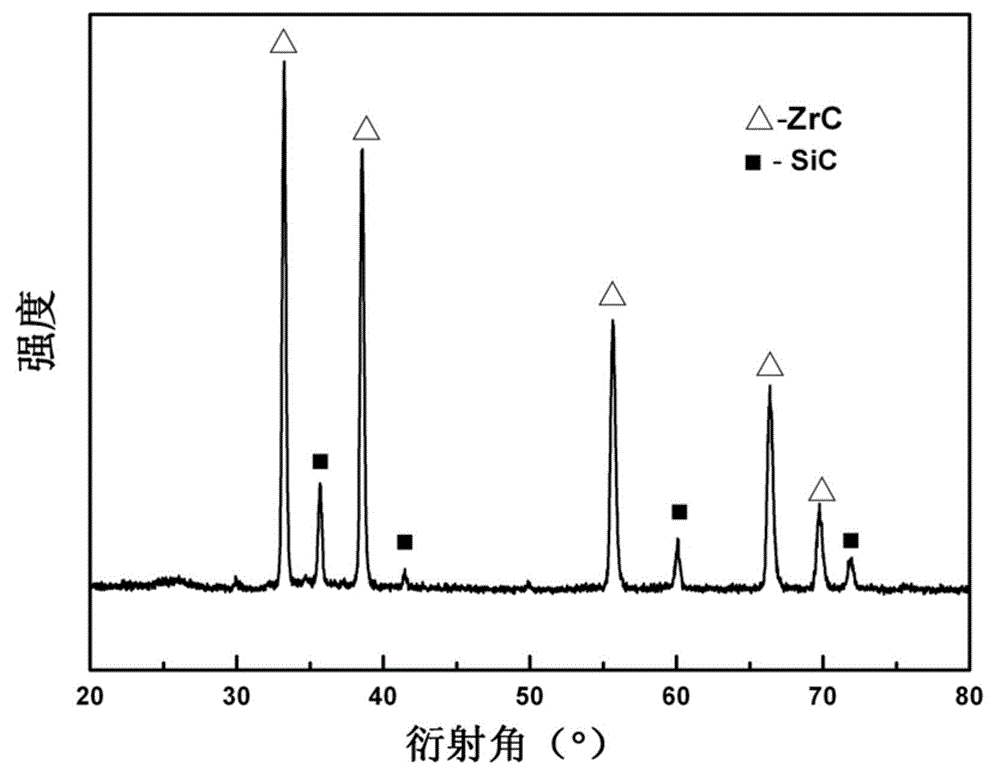

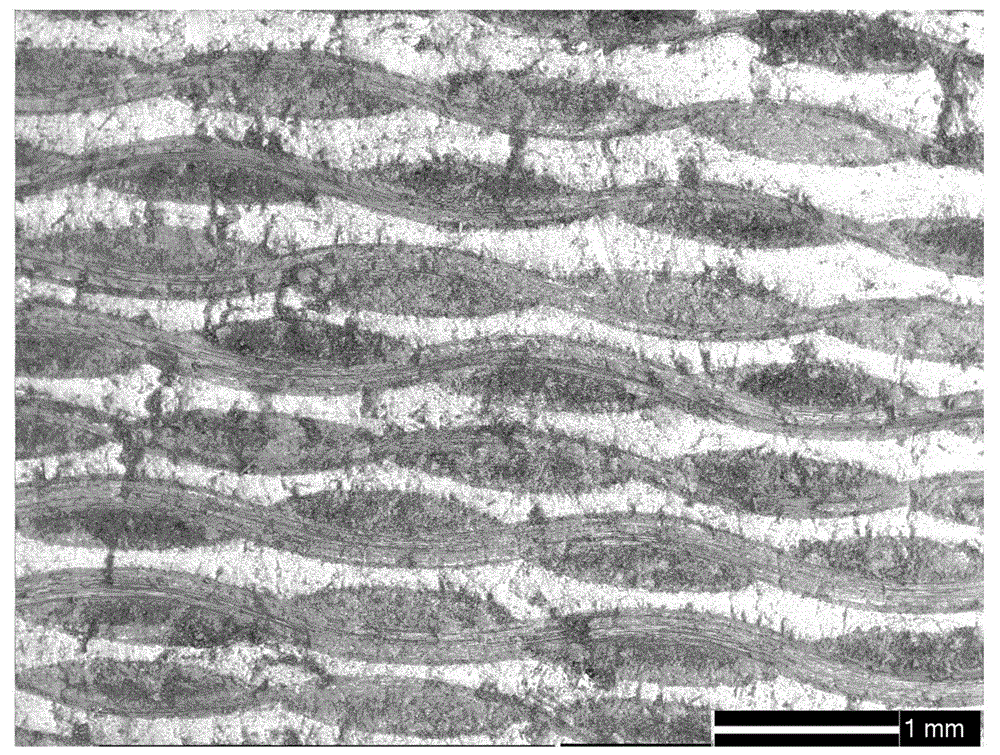

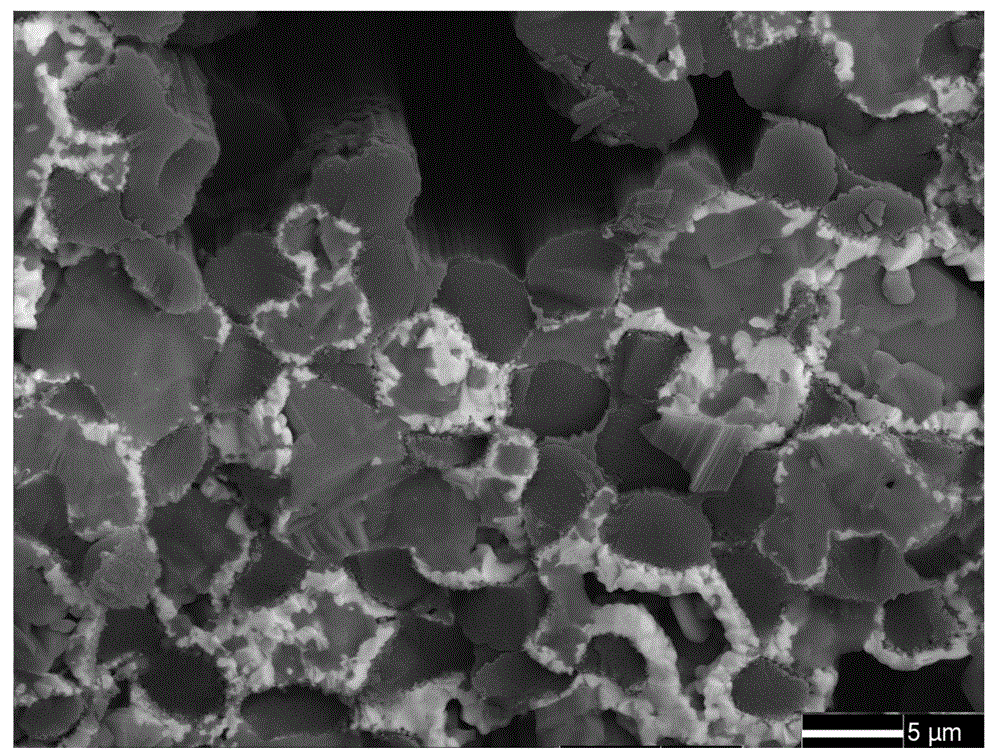

[0025] A kind of preparation method of Cf / ZrC-SiC ultra-high temperature ceramic composite material, ZrSiC 2 The powder is introduced into the carbon fiber fabric, and ZrC and SiC ceramic substrates are generated in situ by hot pressing and sintering, and the final densification process is performed by precursor cracking method to obtain dense Cf / ZrC-SiC ultra-high temperature ceramic composite materials.

[0026] The concrete steps of this method are:

[0027] 1) ZrSi 2 Powder mixed in absolute ethanol, ZrSi 2 The massfraction of is 100g, and the massfraction of dehydrated alcohol is 100g, obtains slurry;

[0028] 2) Brush the slurry obtained in step 1) evenly on the surface of the cut carbon cloth, the quality of the carbon cloth and the slurry is 40g and 200g respectively;

[0029] 3) Stack the carbon cloth brushed with slurry in step 2), and place it in a graphite mold, then put the carbon cloth together with the graphite mold into a high-temperature hot-pressing sinter...

Embodiment 2

[0040]A kind of preparation method of Cf / ZrC-SiC ultra-high temperature ceramic composite material, ZrSiC 2 The powder is introduced into the carbon fiber fabric, and ZrC and SiC ceramic substrates are generated in situ by hot pressing and sintering, and the final densification process is performed by precursor cracking method to obtain dense Cf / ZrC-SiC ultra-high temperature ceramic composite materials.

[0041] The concrete steps of this method are:

[0042] 1) Mix ZrSi2 powder in absolute ethanol, ZrSi 2 The massfraction of is 60%, and the massfraction of dehydrated alcohol is 40%, obtains slurry;

[0043] 2) Brush the slurry obtained in step 1) evenly on the surface of the cut carbon cloth, the mass ratio of carbon cloth to slurry is 1:8;

[0044] 3) Stack up the carbon cloth brushed with slurry in step 2), and place it in a graphite mold, then put the carbon cloth together with the graphite mold into a high-temperature hot-pressing sintering furnace, and inert atmospher...

Embodiment 3

[0054] A kind of preparation method of Cf / ZrC-SiC ultra-high temperature ceramic composite material, ZrSiC 2 The powder is introduced into the carbon fiber fabric, and ZrC and SiC ceramic substrates are generated in situ by hot pressing and sintering, and the final densification process is performed by precursor cracking method to obtain dense Cf / ZrC-SiC ultra-high temperature ceramic composite materials.

[0055] The concrete steps of this method are:

[0056] 1) ZrSi 2 Powder mixed in absolute ethanol, ZrSi 2 The mass fraction of is 80%, and the mass fraction of dehydrated alcohol is 20%, obtains slurry;

[0057] 2) Brush the slurry obtained in step 1) evenly on the surface of the cut carbon cloth, the mass ratio of carbon cloth to slurry is 1:10;

[0058] 3) Stack up the carbon cloth brushed with slurry in step 2), and place it in a graphite mold, then put the carbon cloth together with the graphite mold into a high-temperature hot-pressing sintering furnace, and inert a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Room temperature strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com