Cf/ZrC-SiC ultra-high temperature ceramic-based composite material and preparation method thereof

A technology of ultra-high temperature ceramics and composite materials, which is applied in the field of preparation of ceramic matrix composite materials, can solve the problems affecting the high temperature thermal stability and mechanical properties of composite materials, residues, large metals, etc., and achieve the promotion of infiltration reaction kinetics, low silicon /Effect of carbon residue, low fiber/interface damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

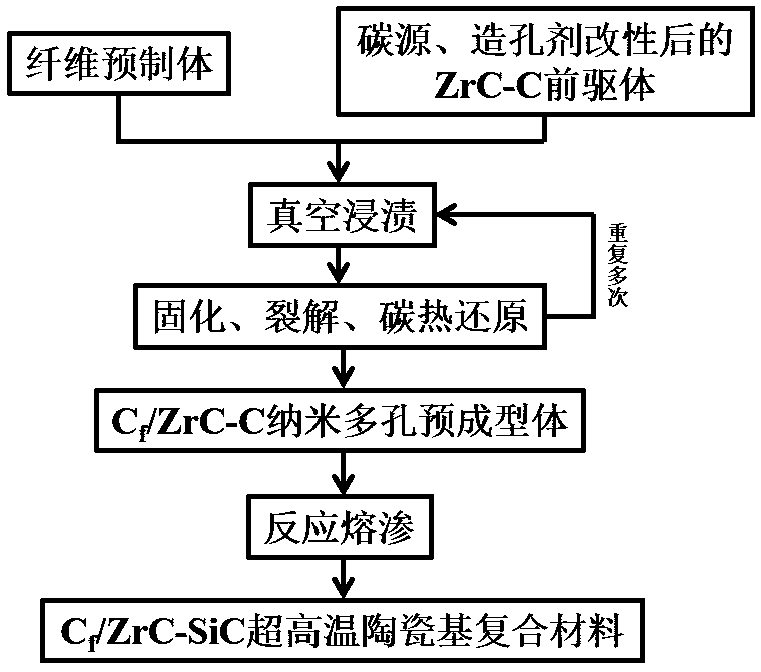

[0036] as a C f / Examples of preparation methods of ZrC-SiC ultra-high temperature ceramic matrix composites, including: (1) modifying ZrC ceramic precursors with pore-forming agents and excess carbon sources to obtain ZrC-C ceramic precursors; (2) by vacuum The above-mentioned modified ZrC ceramic precursor was introduced into the carbon fiber preform by impregnation method, and after curing-cracking-carbothermal reduction, nanoporous C f / ZrC-C preform; (3) Infiltrating molten silicon or molten silicon-zirconium alloy into C f / ZrC-C porous preform for infiltration reaction to obtain C f / ZrC-SiC ultra-high temperature ceramic matrix composites.

[0037] In general, the present invention obtains C by vacuum impregnation of modified ZrC ceramic precursor combined with reactive infiltration f / ZrC-SiC composite material, using the prepared nanoporous C f / ZrC-C preform, which promotes infiltration reaction kinetics, reduces fiber / interface damage and large-size silicon / car...

Embodiment 1

[0041] according to figure 1 The process shown was carried out for preparation:

[0042] (1) Modification of ZrC ceramic precursor: add 20g phenolic resin and 5g polyacrylic acid to 100ml polyziroxane ZrC ceramic precursor, and mix well to obtain ZrC-C ceramic precursor;

[0043] (2) Vacuum impregnation: using the three-dimensional needle-punched carbon fiber braid with a silicon carbide interface as a prefabricated body, vacuum impregnate with the above precursor for 3 hours;

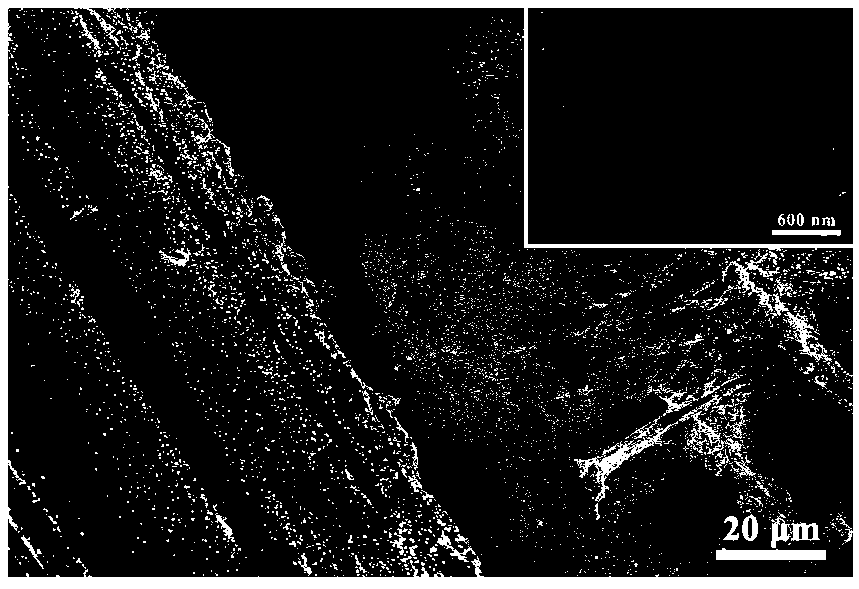

[0044] (3) Curing-cracking-carbothermal reduction: the impregnated material was cured at 140°C for 2h, cracked at 900°C for 2h in an Ar atmosphere, and vacuum carbothermally reduced at 1600°C for 2h to obtain C f / ZrC-C porous preform;

[0045] (4) Reaction infiltration: using high-purity silicon as the silicon source, carry out reaction infiltration in a vacuum environment at 1450 ° C for 1 hour, and the molten silicon and residual carbon react in situ to form a SiC matrix, and finally obtain C f / ...

Embodiment 2

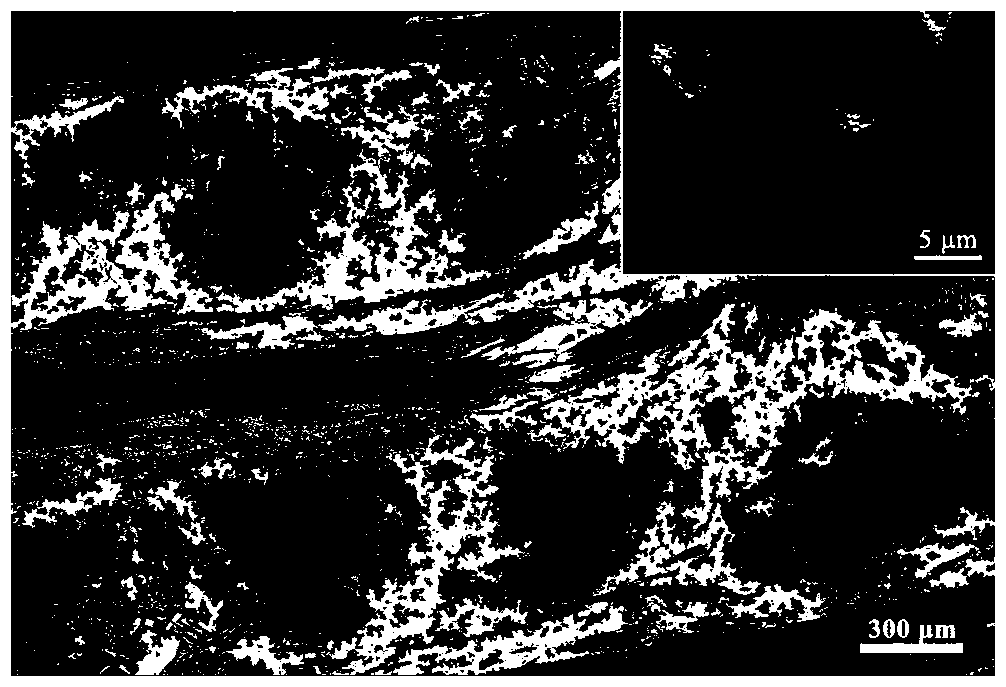

[0049] Embodiment 2 is similar to Embodiment 1, except that steps (2) and (3) are repeated once. The C prepared in this embodiment 2 f / ZrC-C porous preform, the median diameter measured by AutoPore IV 9500V1.09 automatic mercury porosimeter is 9.6 μm, the pore diameter is distributed in a ladder shape and there are a large number of nanopores. C prepared in this example f The open porosity of the / ZrC-SiC composite material measured by the Archimedes drainage method is 1.7%, and the bending strength of the material is 402.5MPa. C prepared in this example f The / ZrC-SiC ultra-high temperature ceramic matrix composite mainly includes carbon fiber, SiC phase and ZrC phase, wherein the content of carbon fiber is 30vol%, and the volume content of ZrC phase and SiC phase are ~40vol% and ~30vol% respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com