Guide-rail injection molding technique of heavy numerically controlled machine

An injection molding process, a technology of heavy-duty CNC machine tools, applied in the direction of large fixed members, mechanical equipment, manufacturing tools, etc., can solve the problem that the guide rail molding method is not suitable for large workbenches, etc., to save plate processing time, improve molding efficiency, The effect of saving finishing man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

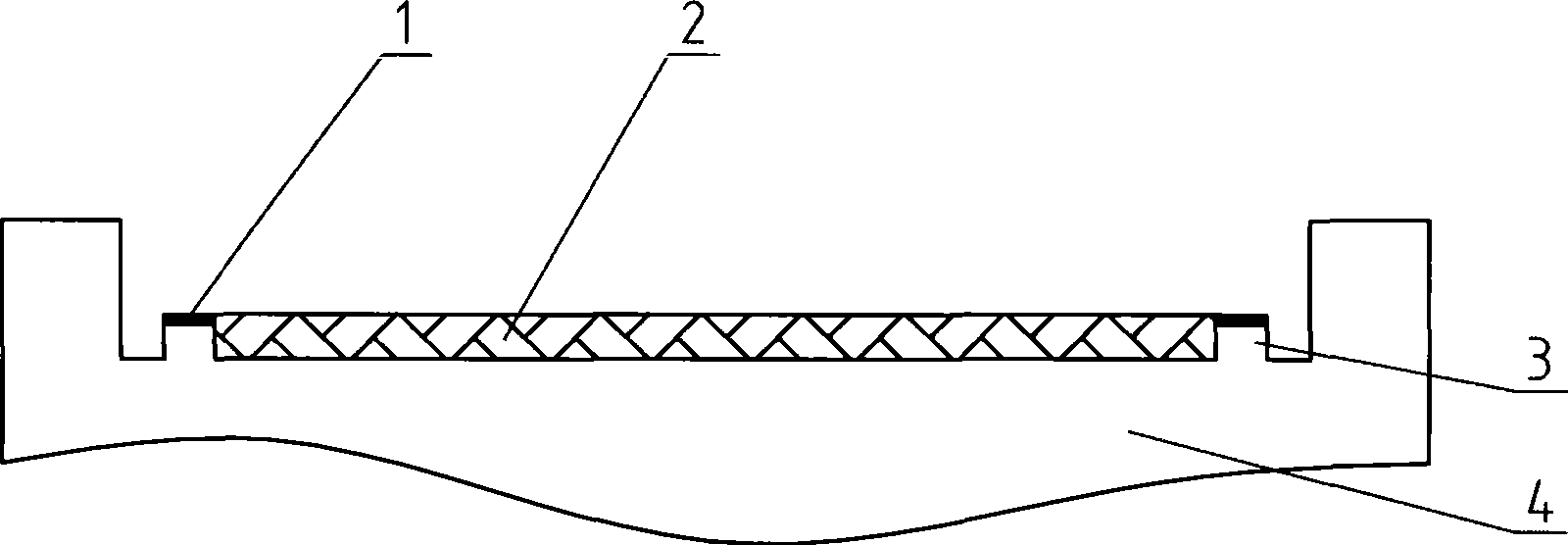

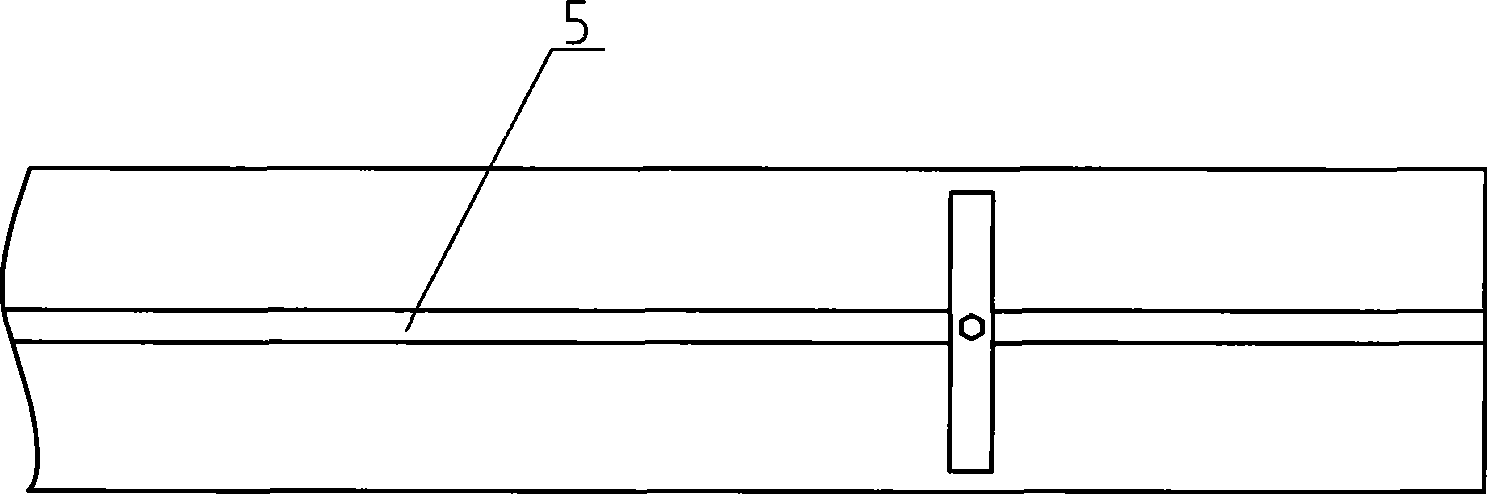

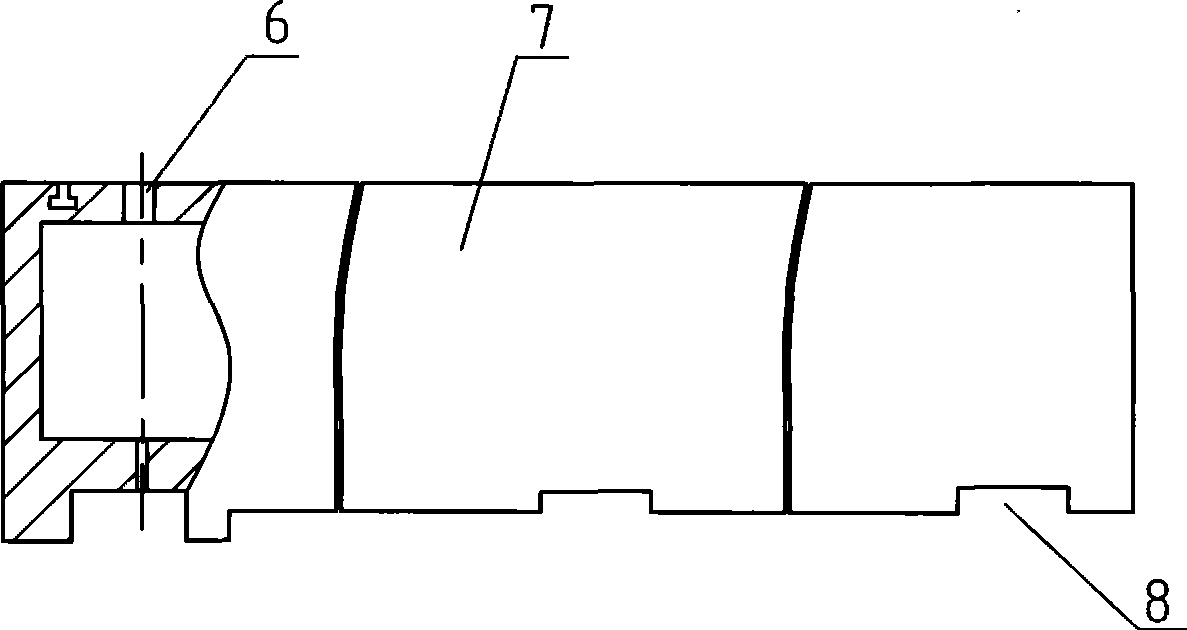

[0033] 1. With reference to the accompanying drawings of the description, in this embodiment, after the assembly accuracy of the bed guide rail 4 meets the requirements and the workbench 7 is processed, a hydrostatic oil chamber 5 is made on the bed guide rail surface, corresponding to the oil chamber to be injected on the bed guide rail. Both sides of the rubber surface 2 are respectively provided with a support edge 3 for supporting the workbench, and the workbench is provided with a plurality of holes 6 for glue injection and exhaust; the process also includes the following steps:

[0034] 1) Seal the oil port with a process plug;

[0035] 2) When making a steel pipe with multiple rows of guide rails connected to each surface to be injected;

[0036] 3) Evenly spray release agent on the contact surface between bed guide rail and adhesive;

[0037] 4) Seal the periphery of the workbench to be injected with a hydrostatic seal level;

[0038] 5) Hoist the workbench on the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com