Preparation method of zirconium oxide implant biological coating and zirconium oxide implant

A bio-coating, zirconia technology, used in coatings, implants, prostheses, etc., can solve the limitation of the application range of zirconia implants, difficult to obtain stable coating structure design, high chemical inertness of zirconia problems, to achieve the effect of promoting the adhesion and growth of bone cells, excellent mechanical strength and biocompatibility, and high matrix bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

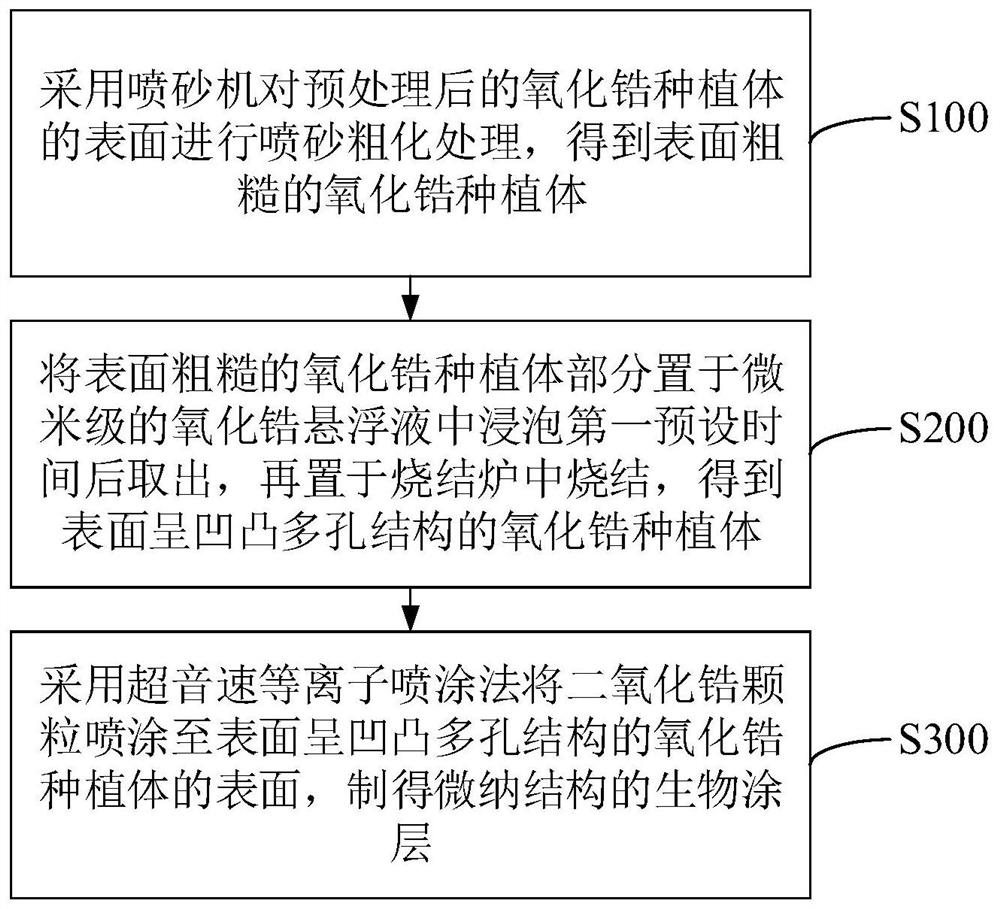

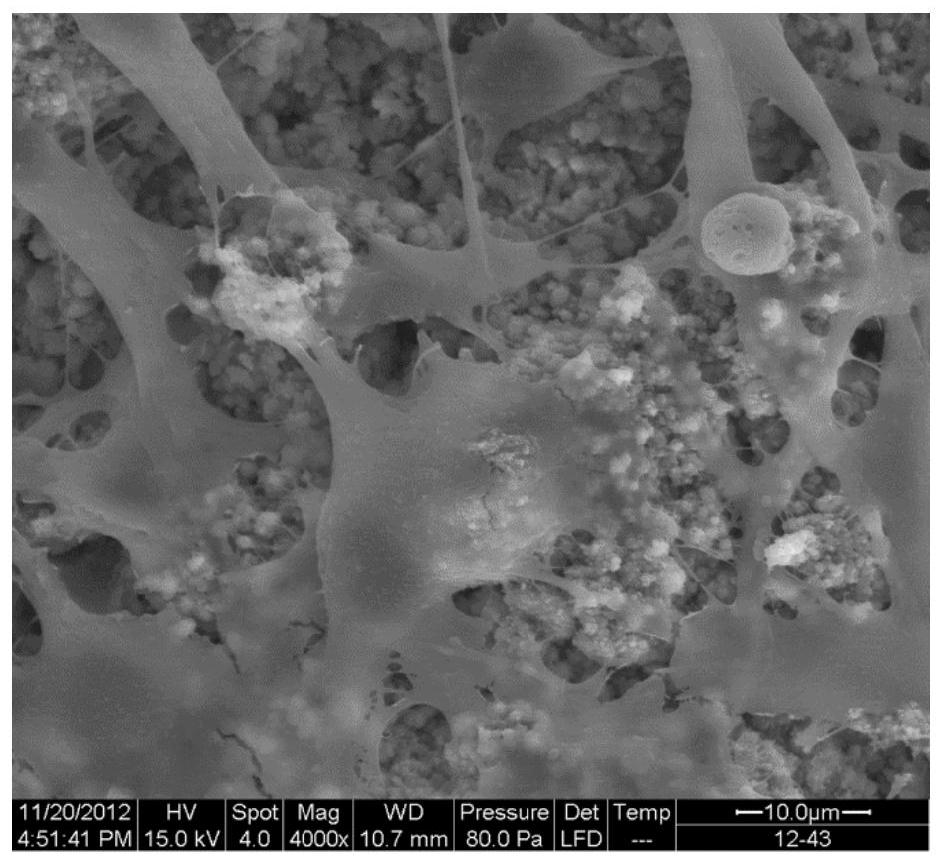

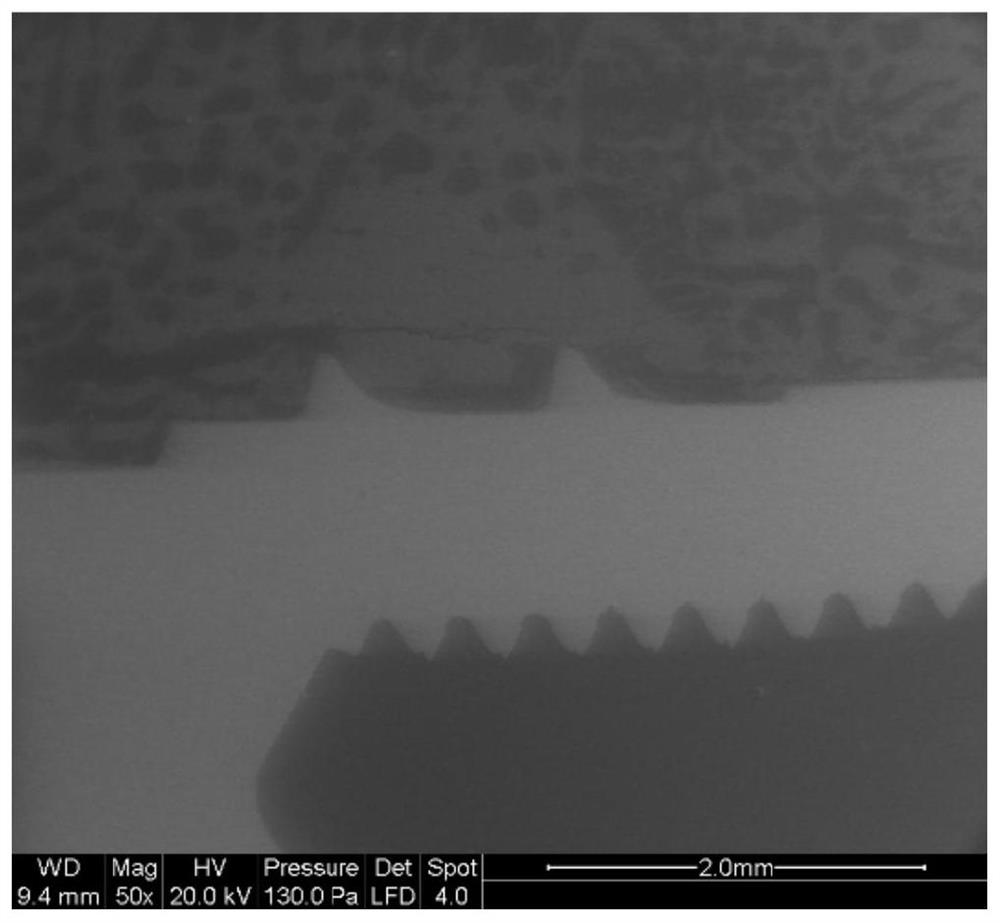

[0037] figure 1 A process flow diagram showing a method for preparing a zirconia implant bio-coating according to an embodiment of the present application. Such as figure 1 As shown, the method includes: step S100, using a sandblasting machine to perform sandblasting and roughening treatment on the surface of the pretreated zirconia implant to obtain a rough surfaced zirconia implant. Then, through step S200, place the rough-surfaced zirconia implant in a micron-sized zirconia suspension, soak it for a first preset time, take it out, and then sinter it in a sintering furnace to obtain a zirconia implant with a concave-convex porous structure on the surface. Zirconium implants. Then, through step S300, the zirconia particles are sprayed onto the surface of the zirconia implant with a concave-convex porous structure by using the supersonic plasma spraying method, so as to prepare a bio-coating with a micro-nano structure on the surface of the zirconia implant .

[0038] Ther...

Embodiment 1

[0058] First, the zirconia implants without surface treatment were cleaned and pretreated. The pretreatment process is as follows: first put it into absolute ethanol for ultrasonic cleaning for 20-30s to remove surface oil stains, etc., then put it into deionized water for ultrasonic cleaning for 10-20s, and then put it into a blast drying oven at 50-60°C for 4 hours .

[0059] Then, the dried zirconia implants were roughened by sandblasting. The sand blasting roughening process is as follows: select alumina particles of 10 microns to 200 microns, and set the sand blasting machine under the pressure of 0.7Mpa, blast the nozzle of the vertical sand blasting machine for the zirconia implant, and at the same time spray the zirconia The implant was rotated at a rotation rate of 50° / s, the distance between the nozzle and the zirconia implant was 2 cm, and the nozzle was perpendicular to the implant and sprayed uniformly for 40 s.

[0060] At the same time, the zirconia suspension...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com