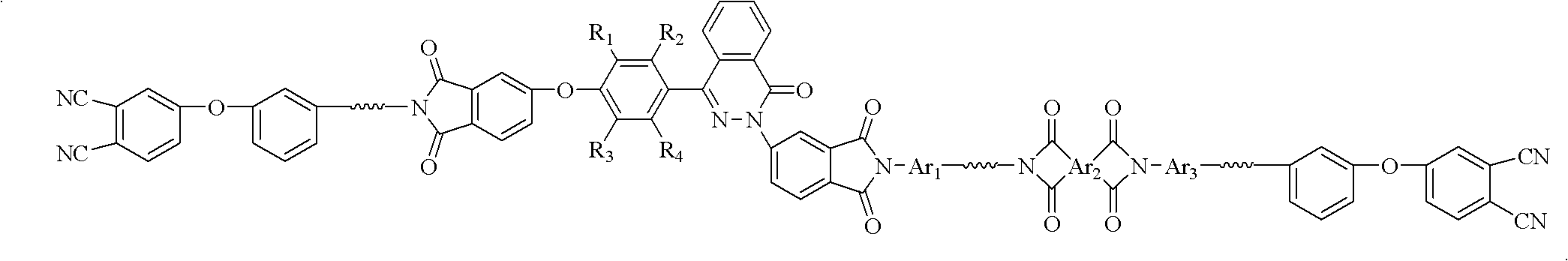

Phthalonitrile-terminated polyimide resin containing phthalazinone structure, cured product and preparation method thereof

A technology of polyimide resin and phthalonitrile, which is applied in the field of polymer material synthesis, can solve the problems of narrowness, high energy consumption for processing and molding, and processing window accompanied by degradation, and achieves wide application prospect and processing and molding performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 Preparation and properties of phthalonitrile-terminated polyetherimide resin containing phthalazinone biphenyl structure and cured product

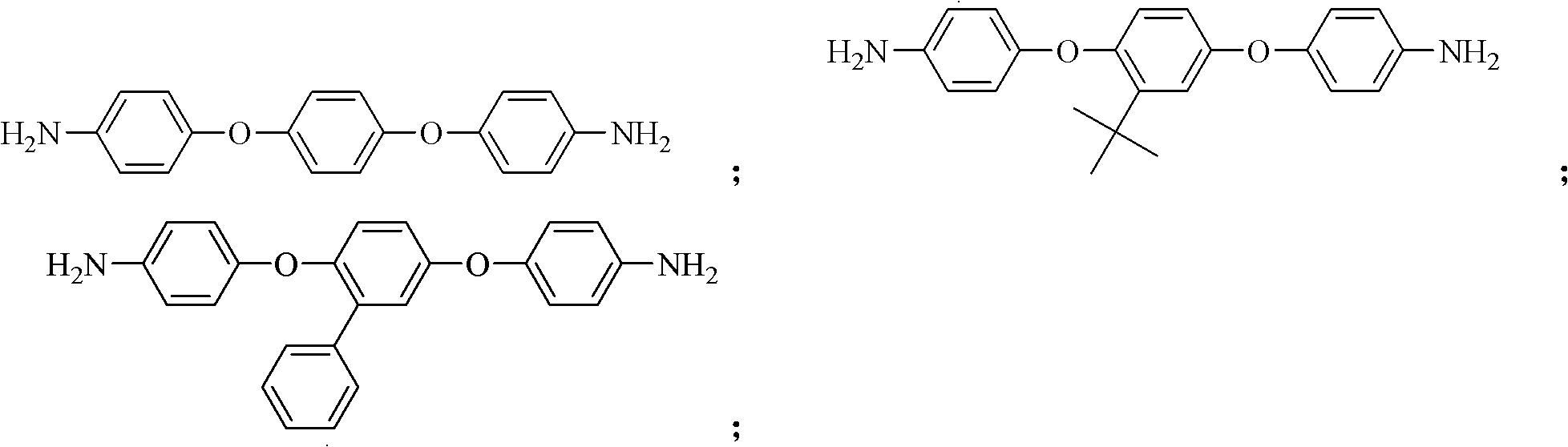

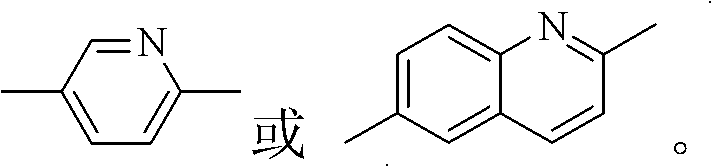

[0043] In a dry three-necked flask equipped with mechanical stirring, a spherical condenser and a nitrogen conduit, accurately add 1.116 g of 2-(3,4-dicarboxyphenyl)-4-[4-(3,4-dicarboxyphenyl) -Oxygen)-phenyl]-2,3-phthalazin-1-one dianhydride (2.1mmol) and 0.21g of 4,4'-diaminodiphenyl ether (1.05mmol), under nitrogen protection Add 12 mL of m-cresol (m-cresol) and a catalytic amount of isoquinoline, react at room temperature for 3 h, then raise the temperature to 180° C. and continue the reaction for 16 h. Cool the reaction solution to room temperature, add 0.569g of 4-(3-aminophenoxy)phthalonitrile (2.1mmol) under nitrogen protection, stir at room temperature for 3h, then raise the temperature to 180°C to continue the reaction for 12h, after the reaction , The reaction solution was precipitated with 300mL of methanol, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com