Method of reducing laser ignition energy

A laser ignition and energy technology, which is applied in the direction of weapon accessories, blasting barrels, fuzes, etc., can solve the problems of reducing laser ignition energy, difficulty in safety control and stabilization measures, general light absorption performance, etc., and achieve the effect of improving the effect of secondary heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

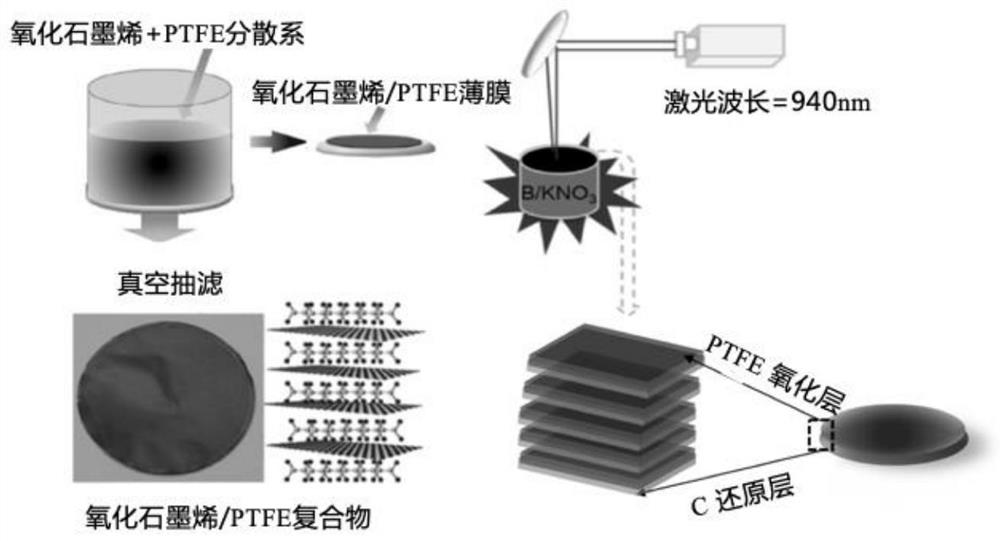

[0031] Dissolve 100 mg of graphite oxide in 20 ml of deionized water, followed by gentle sonication for 10 min in an ultrasonic water bath. A clean aqueous dispersion of graphene oxide at a concentration of 5 mg / ml was then formed and ready for vacuum filtration. During vacuum filtration, a GO thin film (GOM) was automatically formed on the upper side of the filter paper. The filter paper has a pore size of 0.45 μm. Self-supporting GO films were obtained by dissolving filter paper in acetone and then drying in a vacuum oven at 60 °C. The energetic material grains are prepared by using the commonly used laser photothermal ignition of the energetic material boron / potassium nitrate mixture. First, the boron / potassium nitrate mixture powder is pressed into a certain size and height of the energetic material grains, and then the graphene-based self-supporting The energetic film and the grain of the energetic material are closely bonded, and they are assembled together into the la...

Embodiment 2

[0034] 120mg of graphene oxide was dispersed in 40ml of water and 20ml of ethanol at room temperature. Then, 86 mg of 3-aminophenol, 200 µl of ammonia solution and 86 µl of formaldehyde solution were added to the above solution. After stirring for 20 h, GO / 3AF was formed and the membrane was obtained by vacuum filtration process. During the filtration, using 10 ml of the above aqueous dispersion, a separate membrane will be formed automatically on the upper side of the filter paper with a pore size of 0.45 μm. The GO / 3AF self-supporting energetic film was directly attached to the surface of the energetic grain. Figure 4 For the comparison of the temperature rise effect of GO, GO@3AF, and 3AF under the action of laser pulses, it can be seen that the photothermal conversion performance of the energetic grain column added with GO@3AF film has been significantly improved.

Embodiment 3

[0036] GO and PTFE composite free-standing membranes were prepared by mixing GO and PTFE in aqueous solution, followed by sonication and filtration. The GO / PTFE composite film is closely attached to the energetic material grain, and the ignition energy of the laser tube explosion under the condition of the self-supporting energetic film before and after the addition of PTFE is compared to study the effect of the addition of PTFE on the regulation of the laser light by the self-supporting energetic film. The effect of hot ignition energy. Such as Figure 8 As shown, the addition of GO / PTFE composite film effectively reduces the threshold power of laser ignition.

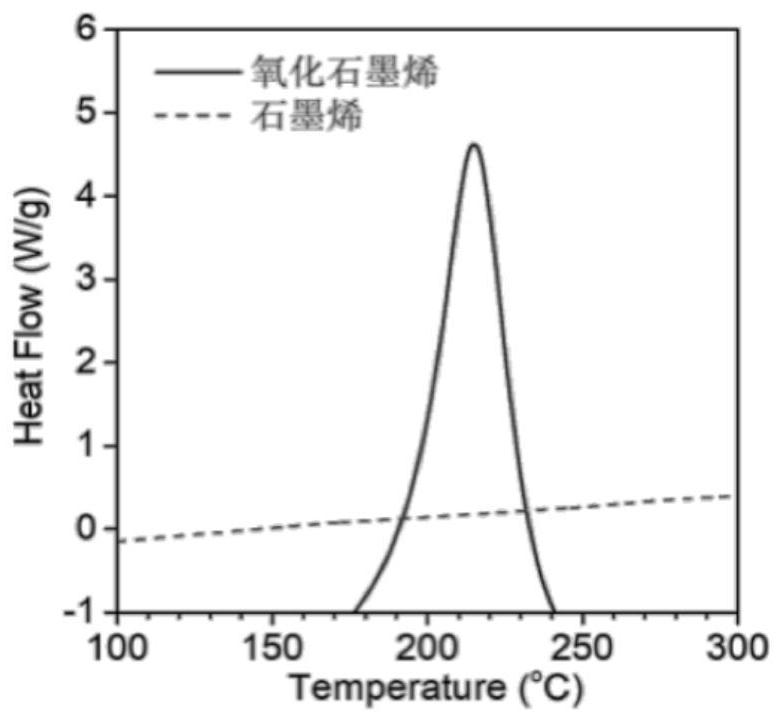

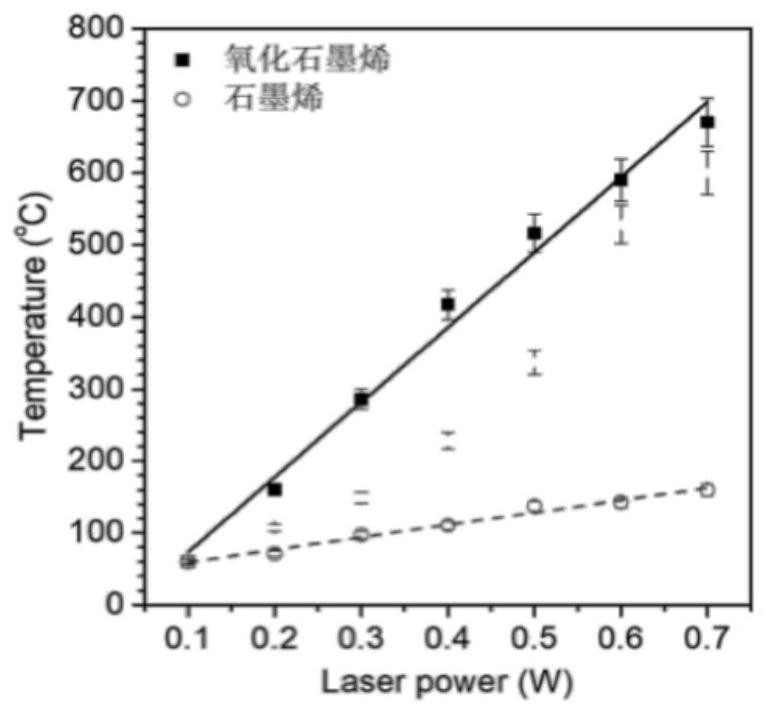

[0037] By monitoring the temperature rise of a series of GO / PTFE self-supporting energetic films during pulsed laser irradiation, the effect of the ratio of GO and PTFE on the temperature rise effect under laser irradiation was studied. Such as Figure 5As shown, pure PTFE shows very low photothermal temperature ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com