Micro internal combustion engine self-heat-storage ignition temperature measuring method and device

A technology of ignition temperature and measurement method, applied in measuring devices, thermometers, measuring heat, etc., can solve the problems of difficult and harsh arrangement of optical windows, affecting heat storage performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for measuring the self-heating ignition temperature of a miniature internal combustion engine, comprising the following steps:

[0026] 1S. In a standard heating furnace, place the thermal storage igniter as a whole in a constant temperature environment for a certain period of time, and measure the static resistance value of the heating wire of the thermal storage igniter at the corresponding temperature;

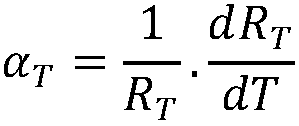

[0027] 2S. By changing the temperature of the heating furnace, the resistance change characteristics of the heat storage igniter heating wire are obtained, and a one-to-one corresponding temperature relationship chart is formed, which is prepared for calculating the temperature characteristics of the transient heating wire in the engine;

[0028] The established temperature resistance relationship is: Rx=R(T)

[0029] Among them: Rx is the resistance of the heating wire, T is the temperature of the heating furnace;

[0030] 3S. Run the internal combustion e...

Embodiment 2

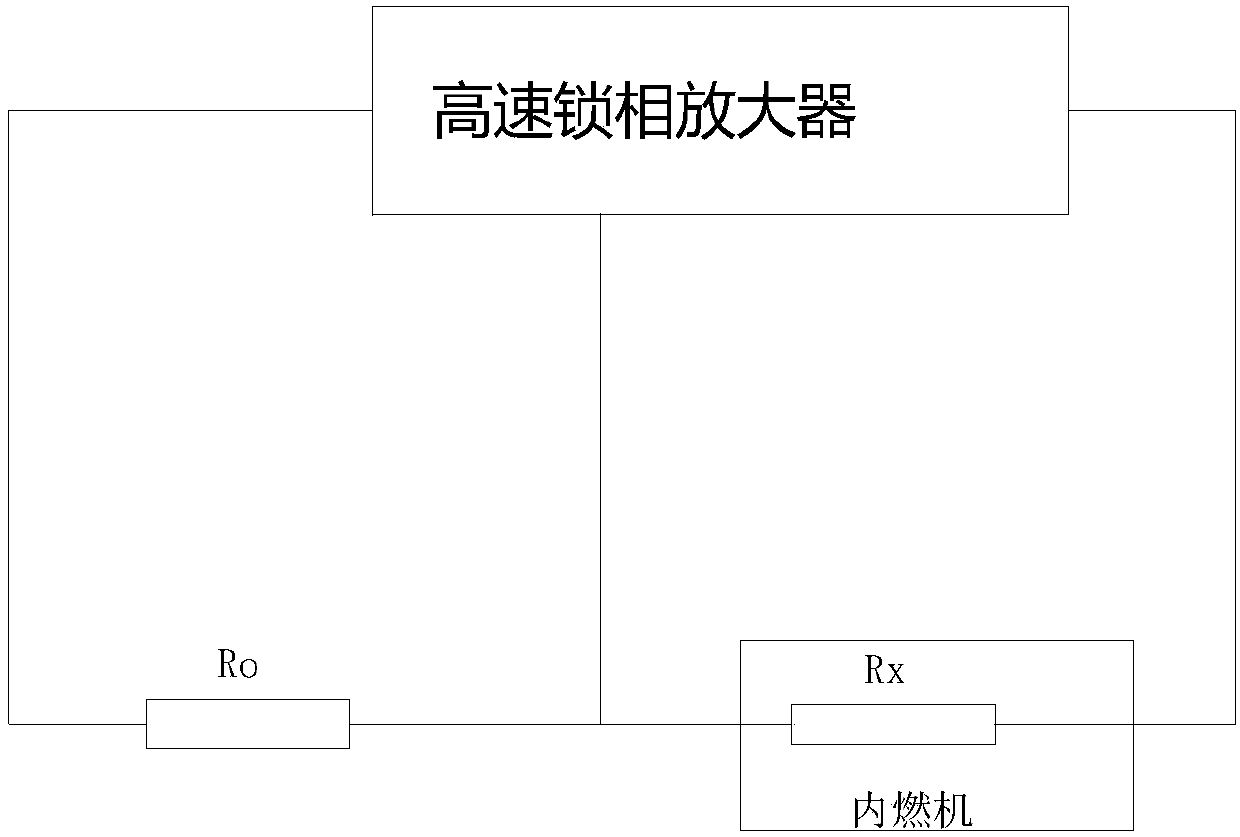

[0036] like figure 1 Shown, a kind of self-heating ignition temperature measuring device of miniature internal combustion engine comprises internal combustion engine, high-speed lock-in amplifier, voltage divider Ro; The heat storage igniter heating wire in the internal combustion engine is resistance Rx to be measured; Described voltage divider Ro and The resistor Rx to be tested is connected in series, and the high-speed lock-in amplifier is connected in parallel with the voltage dividing resistor Ro and the resistor Rx to be tested respectively. The heat storage igniter heating wire is made of platinum or platinum-rhodium alloy. The voltage dividing resistor Ro is a variable resistor with a resistance range of 10-50 ohms.

Embodiment 3

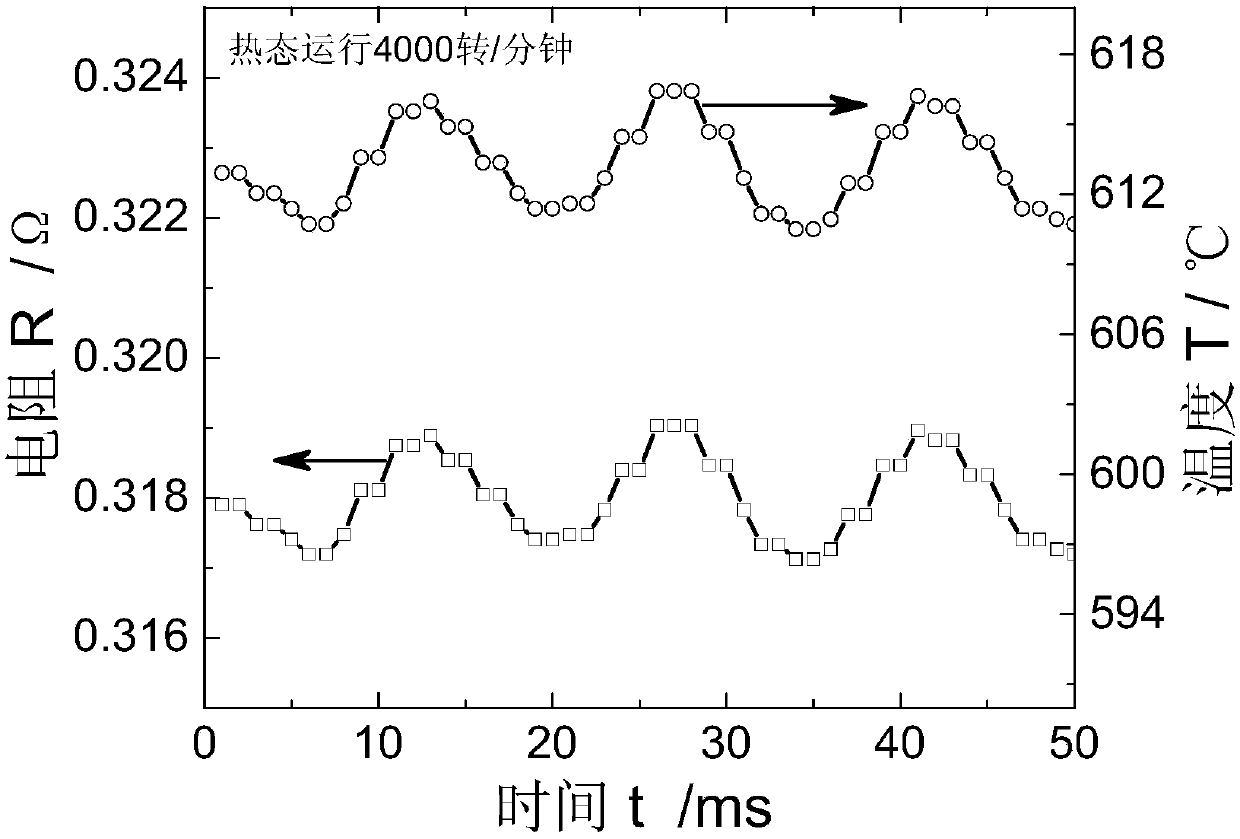

[0038] The heat storage igniter heating wire is made of platinum-rhodium 30 alloy with a diameter of 0.2 mm and a resistance of 0.13 ohms at normal temperature. figure 2 Under the condition of engine running at 4000 revolutions per minute, the resistance R and temperature T of the heat storage igniter heating wire vary with time, which can reflect the periodic change law of the temperature of the engine ignition moment and the temperature in the cylinder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com