Improved thermal ignition method of combustion furnace of sulfur recovery device

A sulfur recovery and combustion furnace technology, applied in the directions of combustion ignition, combustion method, lighting and heating equipment, etc., can solve the problems of increasing the danger of operation, increasing the amount of sour gas flares, etc., to improve ignition efficiency and reduce sour gas emissions. Torch, effect of simplified ignition procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

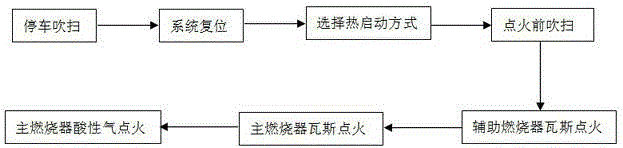

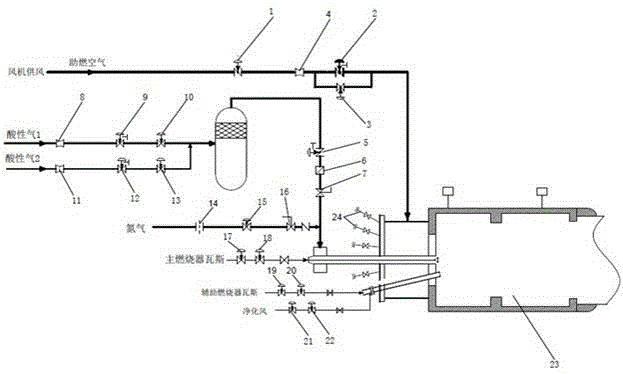

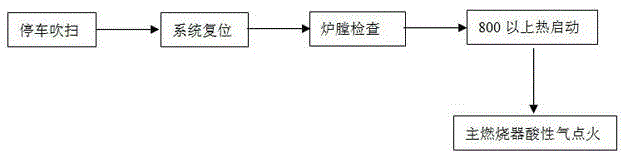

[0036] An improved thermal ignition method for a combustion furnace of a sulfur recovery unit, such as figure 2 and 3 shown, including the following steps:

[0037] (1) Shutdown and purging: When there is an emergency stop of the sulfur recovery unit, start the shutdown interlock, close the gas interlock valves 18 and 19, close the combustion air interlock valve 1 and the combustion air control valves 2 and 3, and close the acid gas interlock valves 10 and 13. Gas inlet furnace control valve 5 and acid gas inlet furnace ball valve 7 stop feeding gas, combustion-supporting air and acid gas into the combustion furnace to prevent a large amount of air and acid gas from entering the furnace during hot start, and avoid flash explosion during ignition. Then press the I-1 stop button, open the nitrogen interlock valve 15 and the nitrogen ball valve 16 to feed nitrogen into the furnace, and purge the furnace for 5 minutes, with a purge flow of about 1000m 3 / h, to exhaust the com...

Embodiment 2

[0043] The difference from Example 1 is that the furnace temperature in step (3) is 1300 degrees. Control the volume ratio of the combustion-supporting air entering the furnace to the acid gas entering the furnace to be 2.4:1.

Embodiment 3

[0045] The difference from Example 1 is that the furnace temperature in step (3) is 1000 degrees. Control the volume ratio of the combustion-supporting air entering the furnace to the acid gas entering the furnace to be 2.1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com