Ignition loss rate tester and testing method

A technology of thermal loss rate and testing method, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., which can solve the problems of human interference, heavy workload, and error-prone test results, and reduce inhalation The risk of toxic and harmful gases, the possibility of reducing the possibility of errors, and the effect of reducing the time of contact with samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

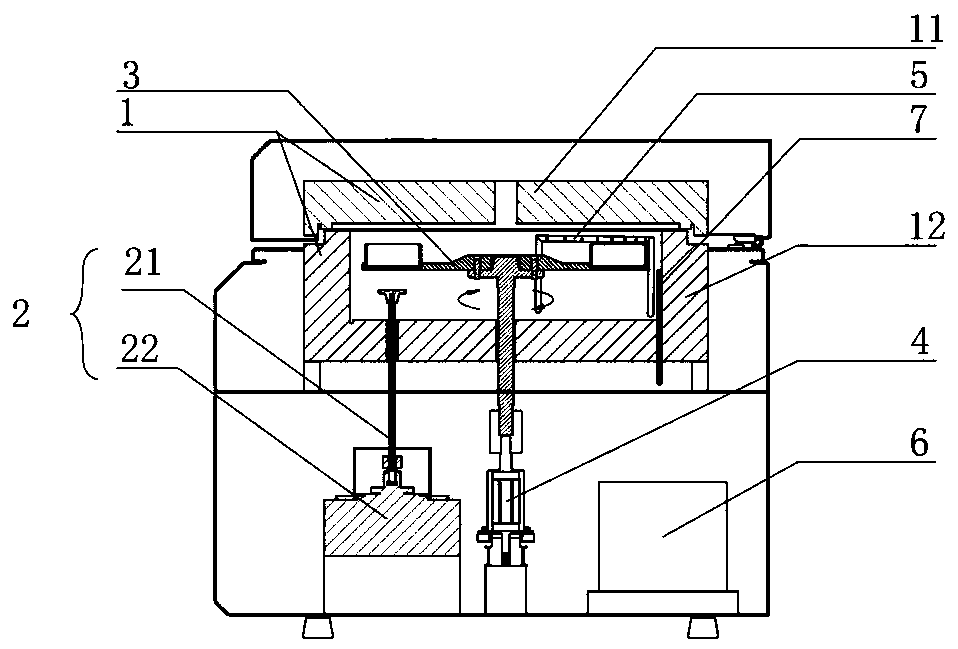

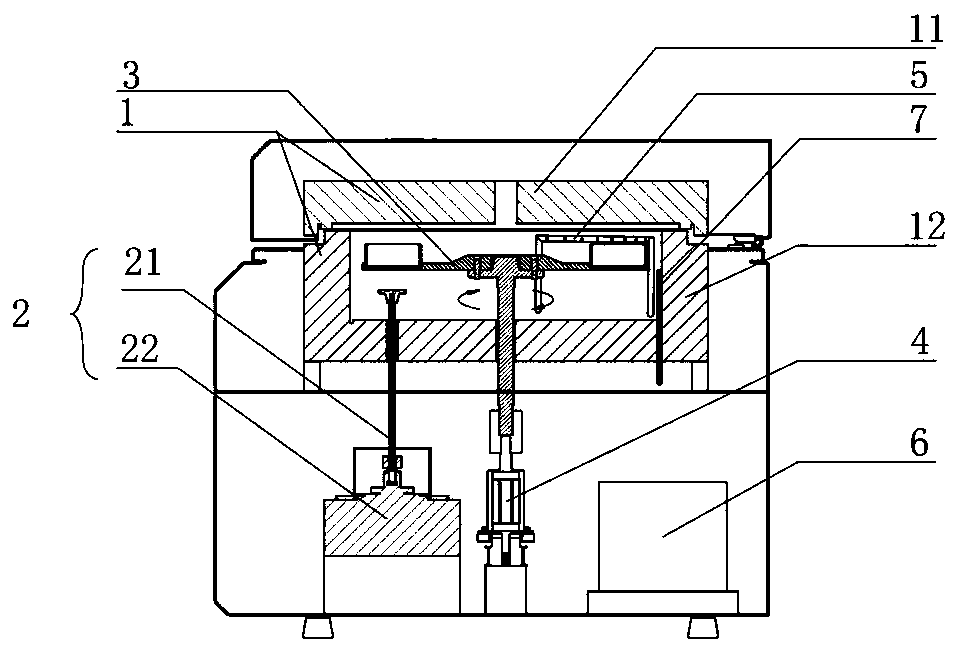

[0046] Such as figure 1 As shown, a thermal loss rate tester includes a housing, and the housing is provided with a heating and heat preservation device 1, a weighing mechanism 2, a lofting plate 3, a lifting and rotating mechanism 4, a ventilation device 5, a controller 6; a lofting plate 3 Set in the heating and heat preservation device 1, the lifting and rotating mechanism 4 is connected with the lofting disk 3, and is used to drive the lofting disk 3 to rotate and lift, and the weighing mechanism 2 is arranged under the lofting disk 3, and is used for weighing and ventilating the crucible The device 5 is arranged in the heating and heat preservation device 1, and is used to pump gas into the heating and heat preservation device 1. The controller 6 is connected with the lifting and rotating mechanism 4 and the weighing mechanism 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com