A hot-fire high-energy gas pulse fracturing device

A technology of high-energy gas and hot spots, applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems such as difficult peak pressure, difficult effect measurement, casing damage, etc., to avoid pressure peak superposition, combustion The state is stable and controllable, and the effect of avoiding casing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

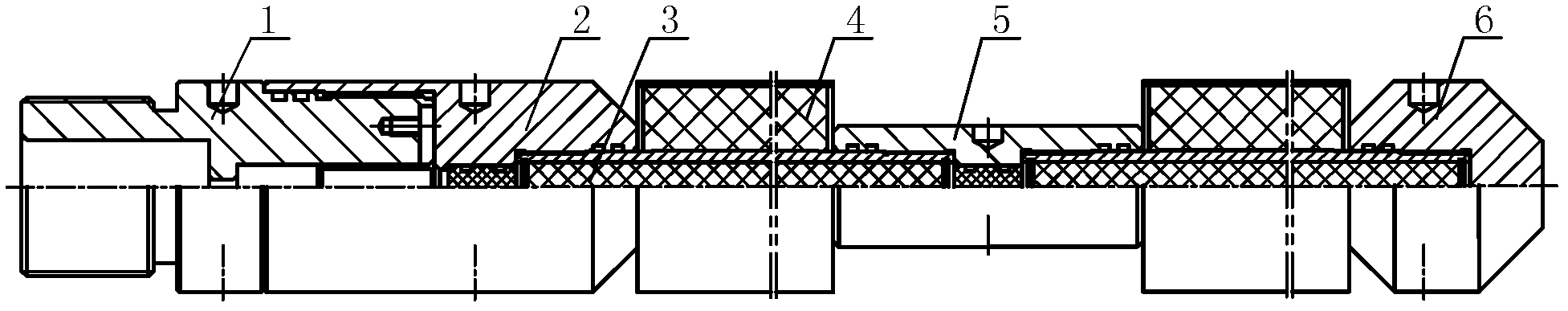

[0026] see figure 1 , the present embodiment provides a thermal ignition high-energy gas pulse fracturing device, which consists of an oil transmission or cable ignition joint assembly 1, a fire transmission joint assembly 2, one or more airtight thermal ignition device assemblies 3, one or more fracturing The main charging assembly 4, one or more serial joint assemblies 5 and the gun tail 6 are composed. According to the distribution of production layers and interlayers, you can choose to assemble or not assemble the fracturing main charge assembly 4, so that the oil transmission or cable ignition joint assembly 1, the fire transmission joint assembly 2, a certain number of closed thermal ignition device assemblies 3 and series joints The 5-unit device of the module is composed of a string of hot-fire high-energy gas pulse fracturing devices for construction.

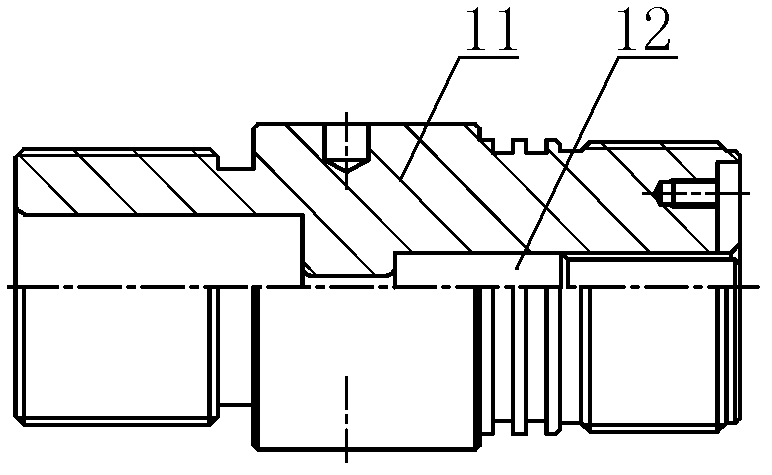

[0027] Oil transmission or cable ignition joint assembly 1 comprises oil transmission or cable joint 11, firing tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com