High-frequency coil preheating ignition structure of parking air heating heater

A technology of high-frequency coils and heaters, applied in heating/cooling equipment, vehicle parts, air handling equipment, etc., can solve the problems of insufficient flame combustion, trouble, and easy formation of carbon deposits, etc., to improve vaporization effect and safety High, guarantee the effect of normal use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

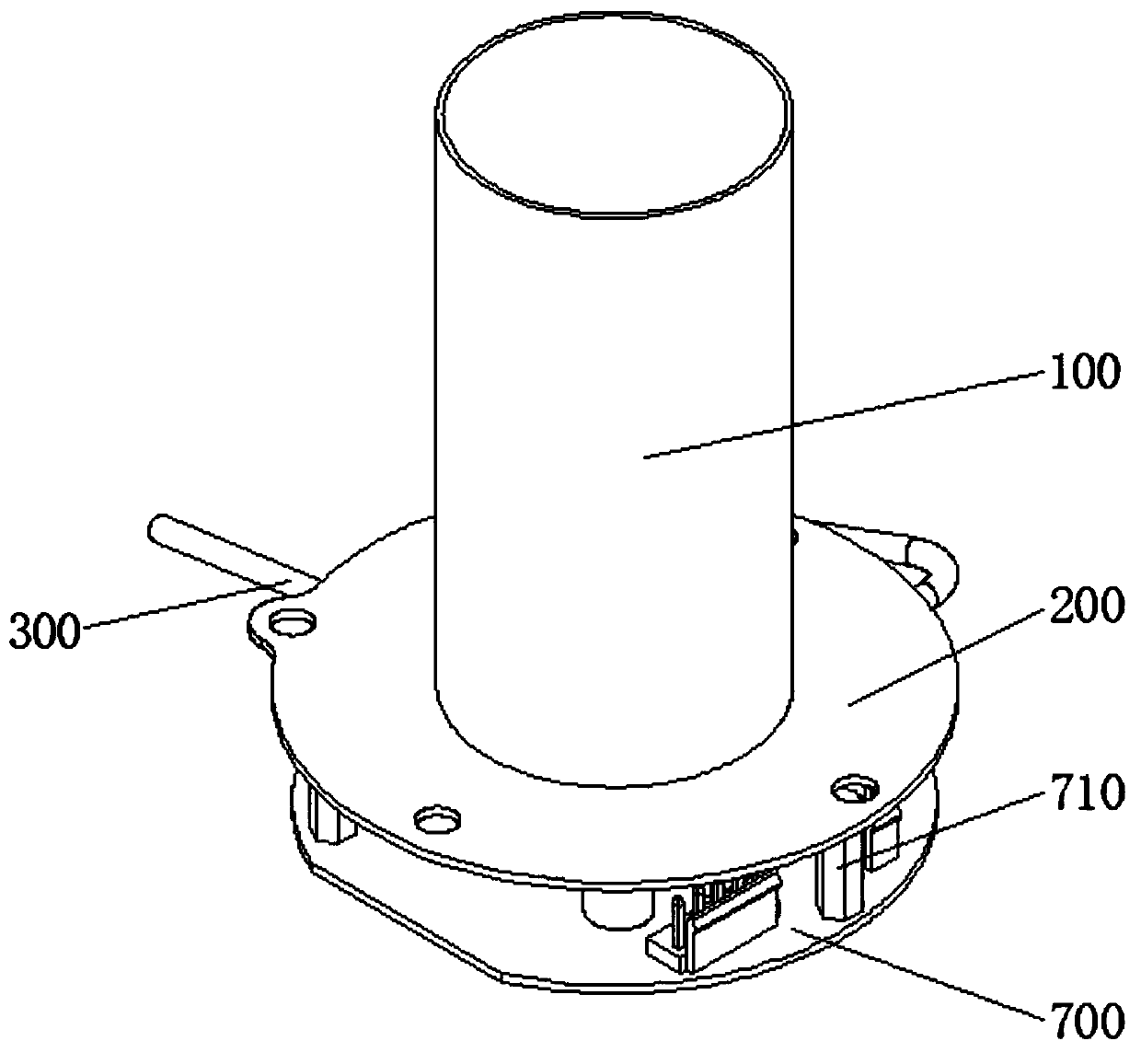

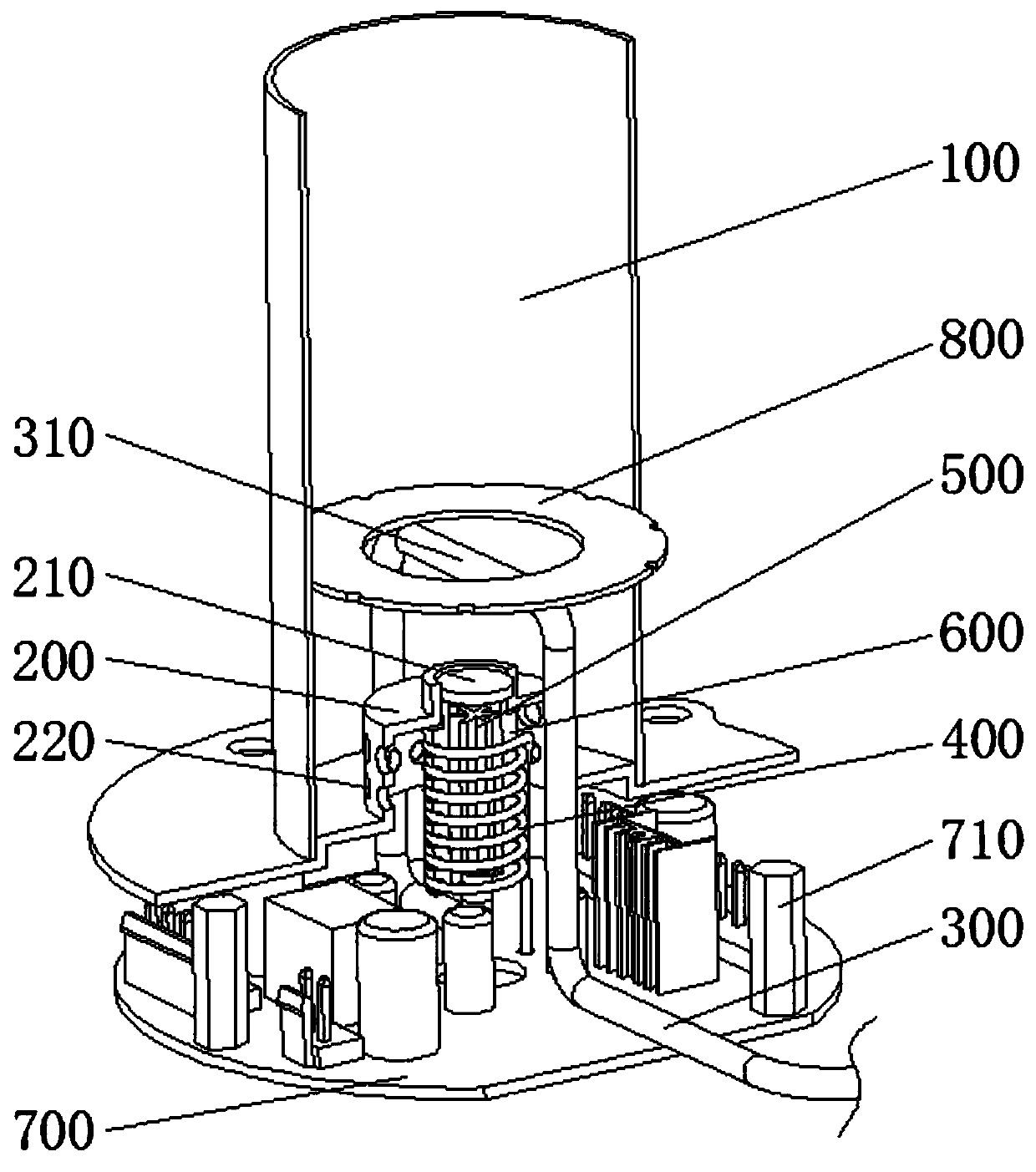

[0015] Such as Figure 1 ~ Figure 2 As shown, a high-frequency coil preheating ignition structure of a parking air heating heater includes a combustion chamber 100 for fuel combustion and a combustion seat 200 arranged at the lower end of the combustion chamber 100 for fixing the combustion chamber 100, and also includes a combustion chamber for The oil pipe 300 for transporting fuel also includes a high-frequency coil 400 placed in the combustion seat 200, and a fuel vaporization metal part 500 placed in the combustion seat 200. A heat-insulating and flame-retardant pipe 600 is arranged between the fuel vaporization metal part 500 and the high-frequency coil 400. The heat-insulating and flame-retardant pipe 600 communicates with the oil outlet of the fuel pipe 300 and forms a channel for fuel circulation. When the high-frequency coil 400 heats the fuel vaporization metal part 500, the fuel in the heat-insulating and flame-retardant pipe 600 is vaporized by the high temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com