Fluidized bed boiler hot material firing mode

A fluidized bed boiler and hot material technology, applied in fluidized bed combustion equipment, combustion ignition, incandescent ignition, etc., can solve the problems of cumbersome operation process, complex facilities, high cost, and achieve strong controllability, cost reduction, The effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

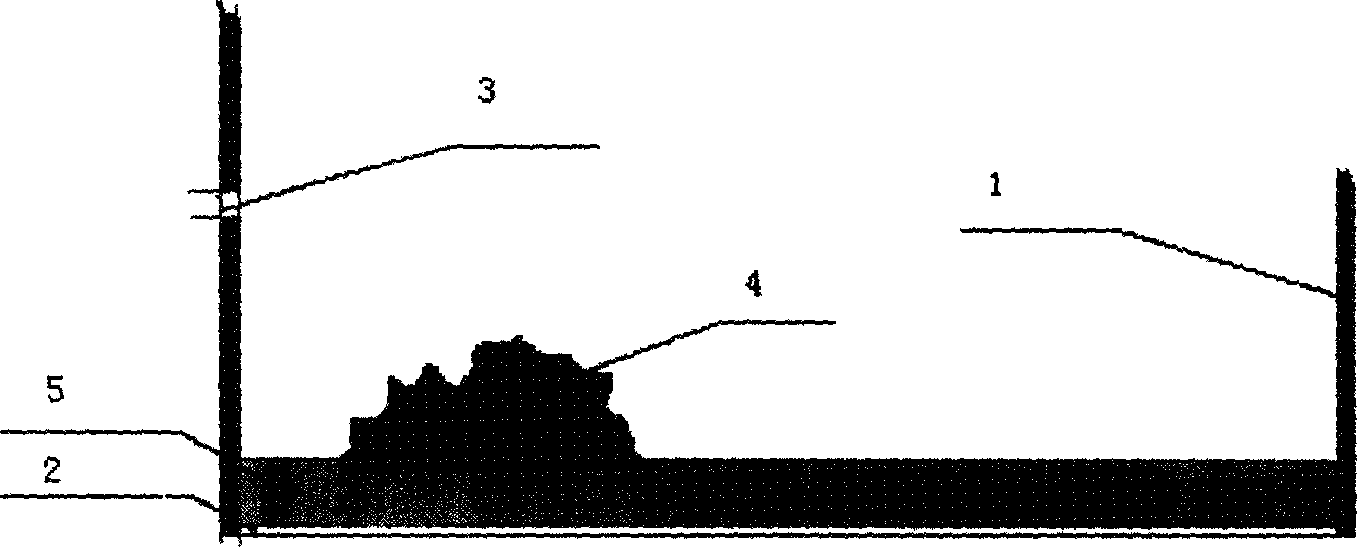

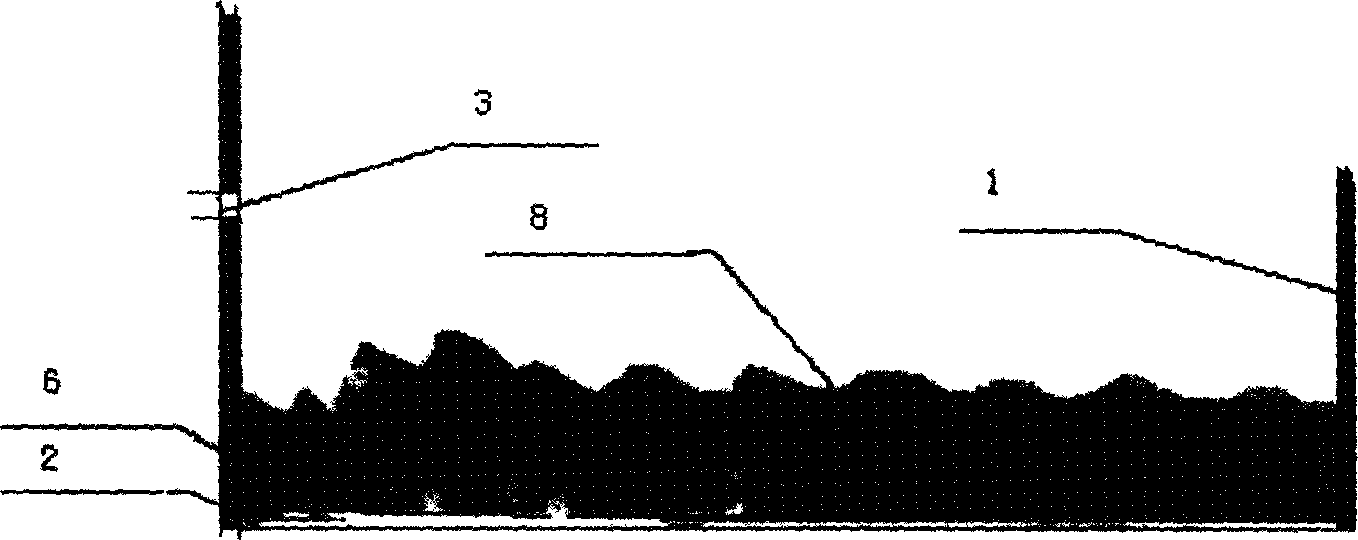

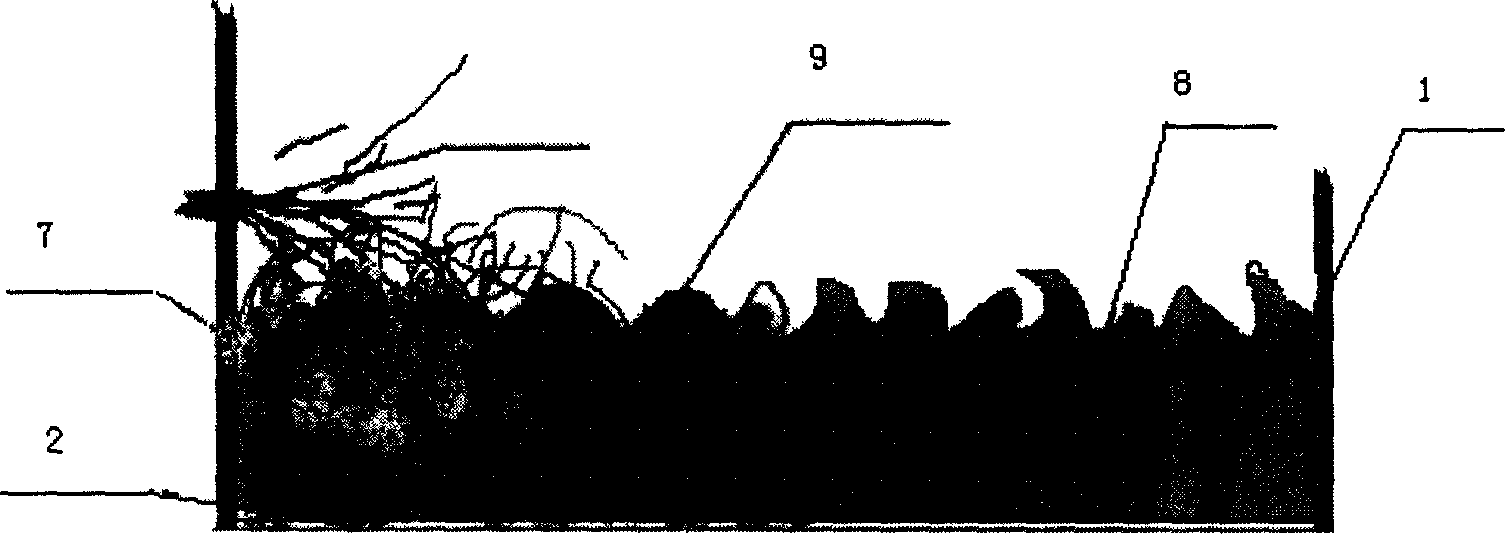

[0020] Hot material ignition method and steps of the present invention:

[0021] 1. Take the cold slag discharged from the operating boiler as the bottom material for starting the boiler. The particle size of the cold slag is 2-8mm, and its particle size ratio is: 2-3mm accounts for 25%; 3-6mm accounts for 50%; 6-8mm accounts for 25% ;The bottom material thickness is 330mm;

[0022] 2. Before taking hot material, stop the slagging of the running boiler. When the wind pressure in the air chamber rises to 108% of normal and the temperature in the dense phase zone remains at 900°C, take the hot material;

[0023] 3. Align the feeding cart with the feeding port, open the furnace door, and automatically fill the hot material into the feeding cart under the action of fluidization movement. Fill in, determine and repeat several times according to the size of the material truck volume, and take a total of 1 ton of hot material. The hot material placed in the furnace of the pre-start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com