Method and device for detecting glow ignition of an internal combustion engine in a motor vehicle

A hot ignition, internal combustion engine technology, used in engine ignition, internal combustion engine testing, machine/engine and other directions, can solve problems such as inability to identify hot ignition, achieve high resolution accuracy, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

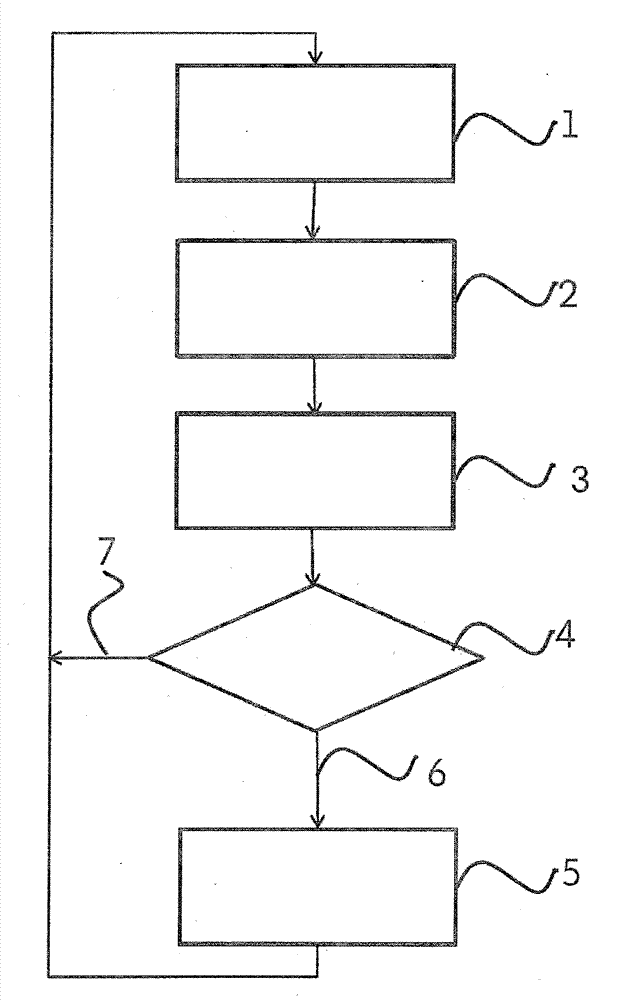

[0027] exist figure 1 The method according to the invention is schematically shown in . After the measurement 1 of the time segment of the first cylinder and the at least one other cylinder, a reference signature 2 for hot ignition is formed by comparing the time segment of the first cylinder with the time segment of the at least one other cylinder. As a function of the comparison, a signal 3 for detecting a glowing ignition is subsequently generated. The signal is compared with the theoretical value 4, to what extent the theoretical value is maintained. Maintaining the theoretical values 7, the method according to the invention was carried out again. If the theoretical value 6 is not maintained, countermeasures 5 for hot ignition are taken, such as interrupting the fuel supply, reducing the boost pressure, reducing the fresh gas charge or cooling the corresponding cylinders. After countermeasure 5, the described method is re-implemented.

[0028] exist figure 2 The ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com