Oil control device and method for solid fire test of extra-high voltage alternating-current transformer

A UHV AC and test oil technology, which is applied in transformer testing, measuring devices, and lubrication indicator devices, etc., can solve the problems of high operating temperature of UHV AC transformers, difficulty in fire fighting, and high oil temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

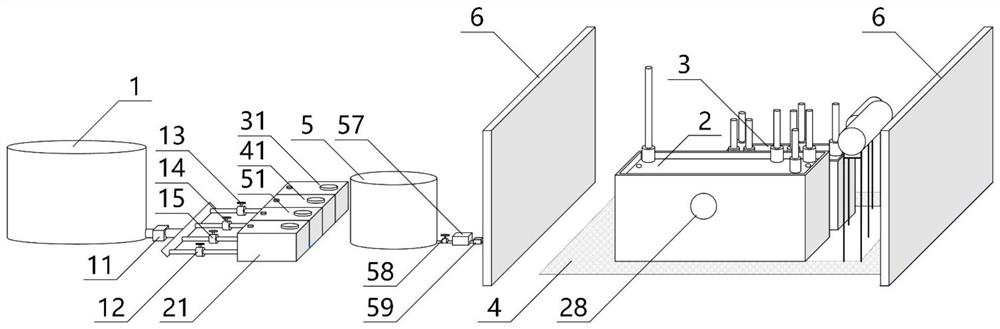

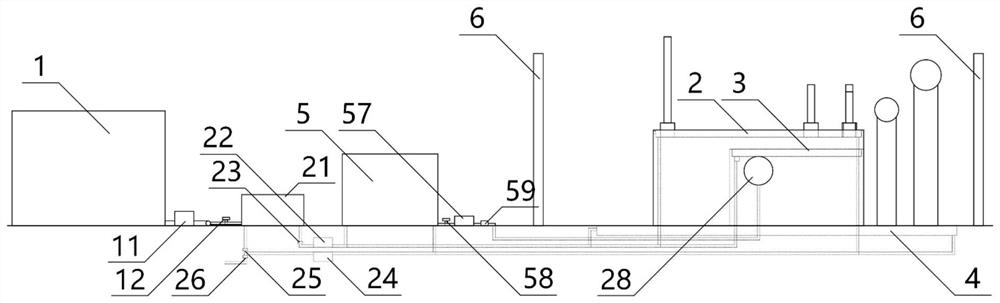

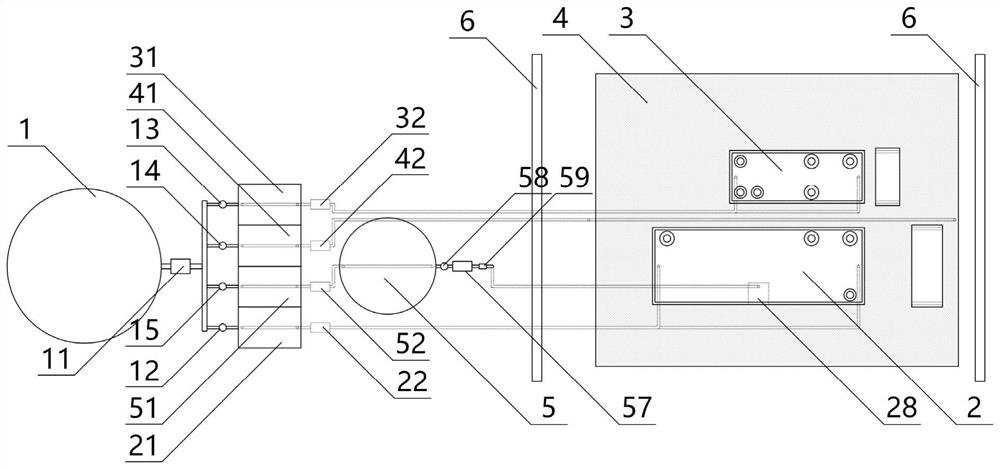

[0078] Such as Figure 5 As shown, an oil control device for a UHV AC transformer solid fire test, including a data acquisition and central control system and an oil storage tank test oil module connected to it, an oil module for the body change test, and an oil module for the adjustment and replacement test , Oil module for oil sump test, oil module for spilled oil storage tank test.

[0079] Such as Figure 5 As shown, the data acquisition and central control system includes a processor, a control loop connected to the processor, and a display; the processor, control loop, and display are all prior art. The oil module for the oil storage tank test, the oil module for the main body transformer test, the oil module for the adjustment and replacement test, and the oil module for the oil sump test are all connected to the control circuit.

[0080] The test oil module of the oil storage tank is used to control the direction of the test oil in the oil storage tank, such as figu...

Embodiment 2

[0107] The present invention also discloses a control method using the above-mentioned oil control device for the solid fire test of the UHV AC transformer, such as Image 6 shown, including the following steps:

[0108] S1: self-test

[0109] Perform self-inspection and other initialization work on all system equipment;

[0110] S2: oil injection

[0111] Open the oil delivery mechanism, the body variable oil injection mechanism, the adjustment and replacement oil injection mechanism, the oil sump oil injection mechanism, and the overflow oil storage tank oil injection mechanism according to the predetermined plan; specifically, open the body variable oil delivery valve 12, the adjustment and replacement oil delivery valve 13, Oil collection pit oil delivery valve 14, overflow oil storage tank oil delivery valve 15, main body variable oil injection valve 23, said adjustment and replacement variable oil injection valve 33, oil collection pit oil injection valve 43, overflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com