Low-temperature SCR catalyst prepared by extrusion molding, and preparation method thereof

A technology of SCR catalyst and low-temperature flue gas, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of unfavorable ecological environment and human health, high reaction temperature, dust blockage, etc., and achieve excellent low temperature Effects of SCR characteristics, increased specific surface area, and reduced operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

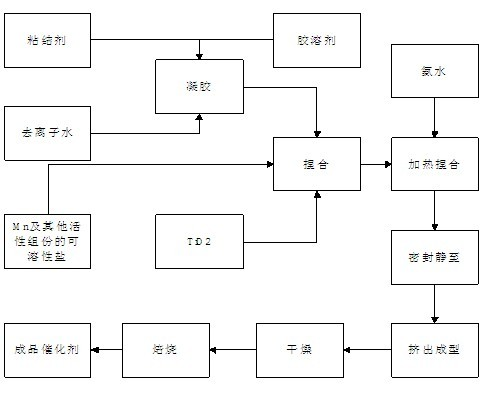

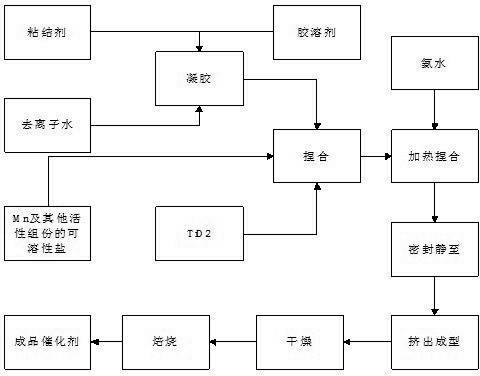

Method used

Image

Examples

Embodiment 1

[0035] Dissolve 5 grams of polyvinyl alcohol (PVA) in 100 grams of deionized water, raise the temperature to about 80°C to promote its complete dissolution, add 2 grams of oxalic acid after cooling, and stir evenly to form a transparent gel for later use.

[0036] Add 80 grams of 50% manganese nitrate solution to 100 grams of deionized water, and then mix with 200 grams of nano-TiO 2 The powder is mixed and put into a kneader for kneading. After forming a slurry, add the above gel and continue kneading. During the kneading process, the temperature is gradually increased (at a rate of 0.5°C / min). As the kneading continues, water will evaporate. When the temperature rises to 70-95℃, the viscosity of the mixture will increase rapidly. At this time, add 20 grams of ammonia water with a concentration of 20% (the function of ammonia water is to adjust the pH value of the dough, while the function of water is only to adjust the moisture content of the dough), continue Knead until the...

Embodiment 2

[0042] Dissolve 5 grams of polyvinyl alcohol (PVA) in 100 grams of deionized water, raise the temperature to about 80°C to promote its complete dissolution, add 2 grams of oxalic acid after cooling, and stir evenly to form a transparent gel for later use.

[0043] Add 350 grams of 50% manganese nitrate solution to 100 grams of deionized water, and then mix with 200 grams of nano-TiO 2 The powder is mixed and put into a kneader for kneading. After forming a slurry, add the above gel and continue kneading. During the kneading process, the temperature is gradually increased (at a rate of 0.5°C / min). As the kneading continues, water will evaporate. When the temperature rises to 70-95°C, the viscosity of the mixture will increase rapidly. At this time, add 20 grams of 20% ammonia water and continue kneading until the viscosity reaches the optimum. Stop kneading.

[0044] Take out the dough-like precursor, put it in an airtight container and let it stand for 10 hours, then put it in...

Embodiment 3

[0049] Dissolve 5 grams of methylcellulose in 100 grams of deionized water at about 80°C, add an appropriate amount (4 grams) of citric acid after cooling, and stir evenly to form a transparent gel for later use.

[0050] Add 80 grams of 50% manganese nitrate solution and cerium nitrate crystals to 200 grams of deionized water, the molar ratio of Mn: Ce is 40:7, and then mix with 400 grams of metatitanic acid (as TiO 2 325 grams in total) mixed into a kneader for kneading, after forming a slurry, add the above gel to continue kneading, and gradually increase the temperature (at a rate of 0.5°C / min) during the kneading process, as the kneading continues When the water evaporates, the viscosity of the mixture will increase rapidly when the temperature rises to 70-95°C. At this time, add 20 grams of 20% ammonia water and continue kneading until the viscosity reaches the optimum. Stop kneading.

[0051] Take out the dough-like precursor, put it in an airtight container and let it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com