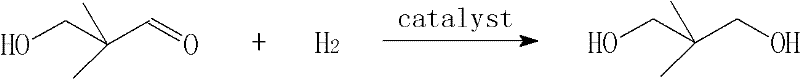

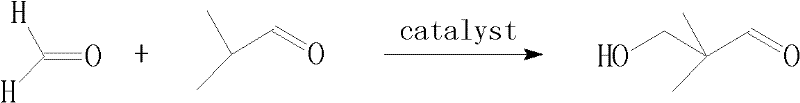

Catalyst for preparing neopentyl glycol by hydrogenation of hydroxypivalaldehyde and preparation method thereof

A technology of hydrogenation catalyst and pivalaldehyde, which is applied to the preparation of hydroxyl compounds, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of cost impact and total yield decline, and achieve The effect of avoiding pollution, stable performance and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

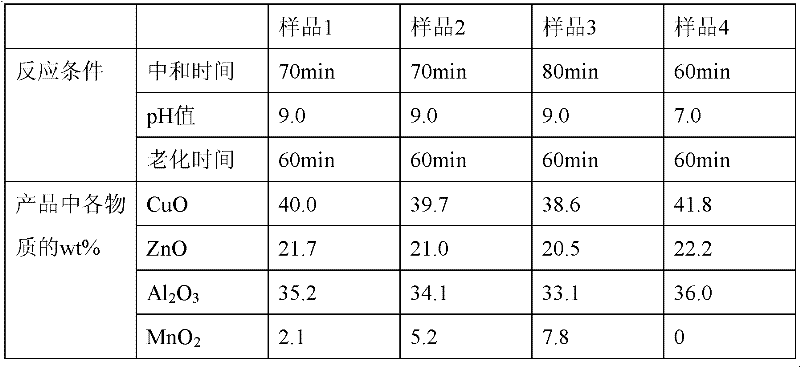

Embodiment 1

[0043] Catalyst preparation method of the present invention is as follows:

[0044] The manganese nitrate solution of 139g aluminum nitrate, 66.9g copper nitrate, 42.7g zinc nitrate, 4.6g 50wt% is mixed with mixed aqueous solution 500ml, and this mixed aqueous solution and mass fraction are the sodium carbonate aqueous solution of 20% and add dropwise to the Neutralize and control the temperature at about 80°C in a heat-preserved and stirred reactor; control the pH value of the reaction system to 9 during the neutralization process, and control the neutralization reaction time at 60 minutes. 1 hour; then, solid-liquid separation, filter cake beating and washing with 40~50 ℃ deionized water, so repeated filtration, beating and washing four times, so that the sodium content in the filter cake after roasting is reduced to below 0.15% (weight) . Dry at 120°C. Then it was calcined at 620°C for 1 hour, and pressed into pellets to obtain the catalyst (sample 1).

Embodiment 2

[0046] The amount of nitrate of copper, zinc and aluminum was the same as in Example 1, and 11.9g of 50% manganese nitrate solution was added. The preparation steps of the catalyst were the same as those in Example 1 to obtain Sample 2.

Embodiment 3

[0048] The amount of nitrate of copper, zinc and aluminum was the same as in Example 1, and 19.6g of 50% manganese nitrate solution was added, and the preparation steps of the catalyst were the same as those in Example 1 to obtain Sample 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com