Preparation method of mesoporous titanium dioxide ball supported Mn-Ce-W compound oxide denitration catalyst

A technology of mesoporous titanium dioxide and composite oxides, which is applied in the direction of metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low-temperature activity, etc., and achieve improved Anti-toxicity, high catalytic activity, effect of improving catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

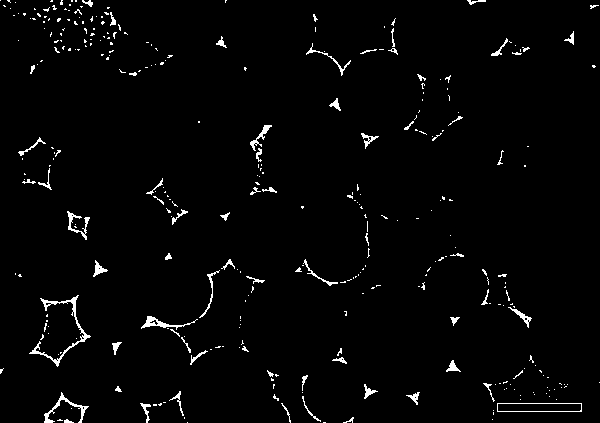

Image

Examples

Embodiment 1

[0020] Take tetraisopropyl titanate and add solvent acetone to prepare a solution with a concentration of 0.005 mol / L, stir at room temperature for 30 min, then transfer the solution to a hydrothermal kettle, and control the filling rate at 60%. o C for 12 h, the product was collected by filtration, washed 3 times with deionized water and solvent, at 60 o C drying, the product is placed in a tube furnace, with 2 o C / min rate of heating up to 400 o C. After calcination for 2 h, mesoporous titanium dioxide balls were obtained after cooling in the furnace. Take the mesoporous titanium dioxide ball, add deionized water with a mass ratio of 1:20 to the mesoporous titanium dioxide ball, and then add manganese acetate, cerium nitrate, and ammonium metatungstate to make the mass of manganese oxide, cerium oxide, and tungsten The mass of oxide accounts for 10%, 10%, and 5% of the total mass respectively, and the rest is titanium dioxide. The mixed solution is stirred at 90 o C was e...

Embodiment 2

[0023] Take tetraisopropyl titanate and add solvent acetone to prepare a solution with a concentration of 0.01 mol / L, stir at room temperature for 30 min, and then transfer the solution to a hydrothermal kettle with the filling rate controlled at 70%. o C for 12 h, the product was collected by filtration, washed 3 times with deionized water and solvent, at 60 o C drying, the product is placed in a tube furnace, with 2 o C / min rate of heating up to 500 o C. After calcination for 2 h, mesoporous titanium dioxide balls were obtained after cooling in the furnace. Take the mesoporous titanium dioxide ball, add deionized water with a mass ratio of 1:30 to the mesoporous titanium dioxide ball, and then add manganese nitrate, cerium nitrate, and ammonium metatungstate to make the mass of manganese oxide, cerium oxide, and tungsten The oxide mass accounts for 5%, 10%, and 5% of the total mass respectively, and the rest is titanium dioxide. The mixed solution is stirred at 90 o C was...

Embodiment 3

[0026] Take tetrabutyl titanate and add solvent ethanol to prepare a solution with a concentration of 0.01 mol / L, stir at room temperature for 30 min, then transfer the solution to a hydrothermal kettle, and control the filling rate at 70%. o C for 12 h, the product was collected by filtration, washed 3 times with deionized water and solvent, at 60 o C drying, the product is placed in a tube furnace, with 2 o C / min rate of heating up to 400 oC, calcined for 4 h, and the mesoporous titanium dioxide balls were obtained after cooling with the furnace. Take the mesoporous titanium dioxide ball, add deionized water with a mass ratio of 1:50 to the mesoporous titanium dioxide ball, and then add manganese nitrate, cerium chloride, and ammonium tungstate to make the mass of manganese oxide, cerium oxide, and tungsten The mass of oxide accounts for 10%, 5%, and 5% of the total mass respectively, and the rest is titanium dioxide. The mixed solution is stirred at 90 o C was evaporated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com