Process for preparing 4-amino diphenylamine

A technology of aminodiphenylamine and aniline, which is applied in the preparation of amino compounds from amines, the preparation of amino compounds by condensation/addition reactions, organic chemistry, etc., which can solve the problems of prolonging the reaction time, increasing energy consumption, difficulty in separation, and difficulty in reaction control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Preparation of composite base catalyst:

[0077] In a 1000 ml three-necked flask equipped with a condenser and a stirrer, add 227.5 grams of 20% (by weight) tetramethylammonium hydroxide aqueous solution (0.50 moles), 10 grams of sodium hydroxide (0.25 moles), 346 grams of 30% tetramethylammonium carbonate aqueous solution (0.5 mol), stirred evenly at 72-77 ℃, promptly made composite base catalyst, concentration 27.3% (weight).

Embodiment 2

[0079] Preparation of composite powder catalyst:

[0080] Take 46 grams of nickel powder, 51 grams of aluminum powder, and 3 grams of iron powder, mix them evenly, and melt them into an alloy in an induction furnace. The molten alloy is sprayed on the high-speed rotating copper drum through the nozzle by the pressure of the gas, and it is rapidly quenched. (The cooling rate can reach 10 5 -10 6 K / S). The cooled alloy is rolled into powder by a ball mill, and sieved to obtain 99.7 grams of 40-300 mesh powder. In a three-necked flask equipped with a thermometer and a stirrer with a capacity of 500 milliliters, 375 grams of a concentration of 20% (weight) of NaOH aqueous solution was added slowly, and the powder prepared above was slowly added, stirred at 60° C. for 4 hours, and then The solid was washed with deionized water until neutral to obtain a composite powder catalyst.

Embodiment 3

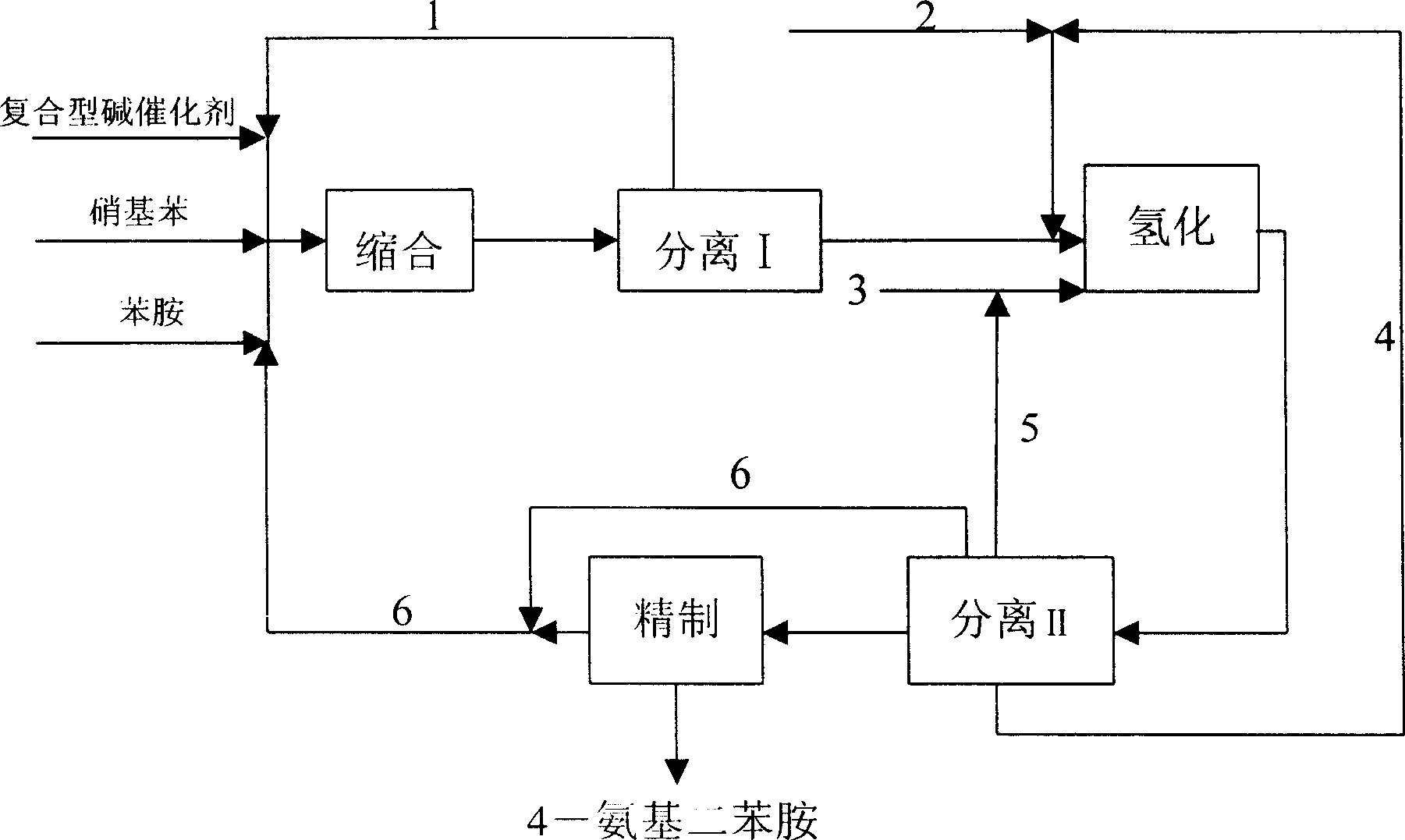

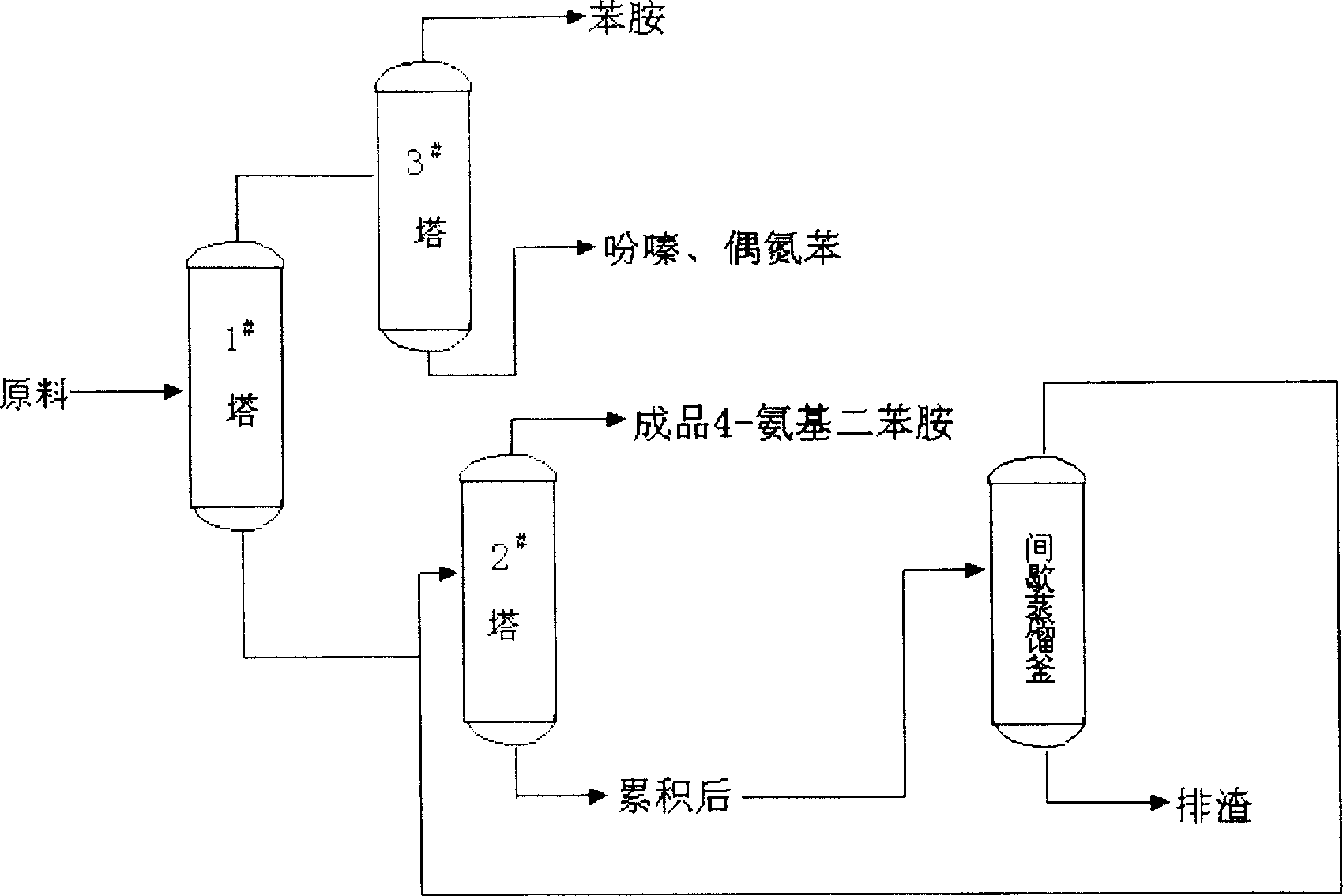

[0082] A. Condensation

[0083] Open the composite base catalyst, aniline and nitrobenzene transfer pump simultaneously under vacuum, adjust the flow rate to 150 kg / hour of aniline, 30 kg / hour of nitrobenzene, and 200 kg / hour of composite base catalyst, the above components Nitrobenzene, aniline and composite base catalysts are continuously fed into the falling film reactor for heating to carry out condensation reaction; the condensation liquid in the falling film reactor is discharged from the lower part into the primary reactor to continue the condensation reaction; part one The condensate at the bottom of the first-stage reactor is returned to the falling film reactor through the circulation pump to form a partial circulation system. The heat medium of the falling film reactor is alcohol vapor at 78-90°C. Control the reaction temperature to 75°C, the pressure to 0.008MPa (absolute pressure), and the flow rate of the circulating fluid to be 1 meter 3 / Hour. The material f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com