Preparation method of graphene supported ruthenium oxide electrode materials

An electrode material, graphene technology, applied in circuits, capacitors, electrical components, etc., can solve the problems of carbon nanotubes with poor electrochemical performance, complicated methods, and high costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

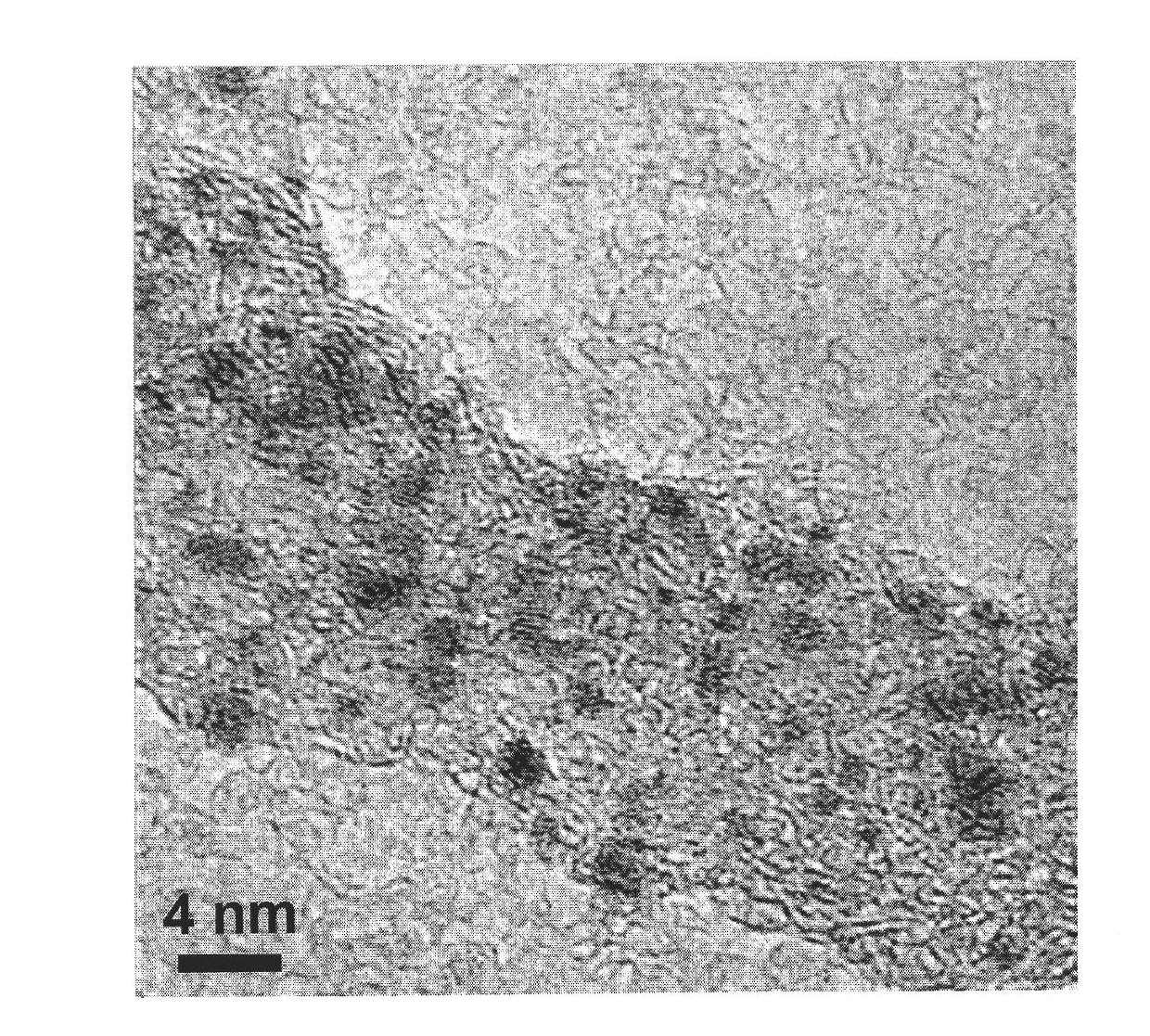

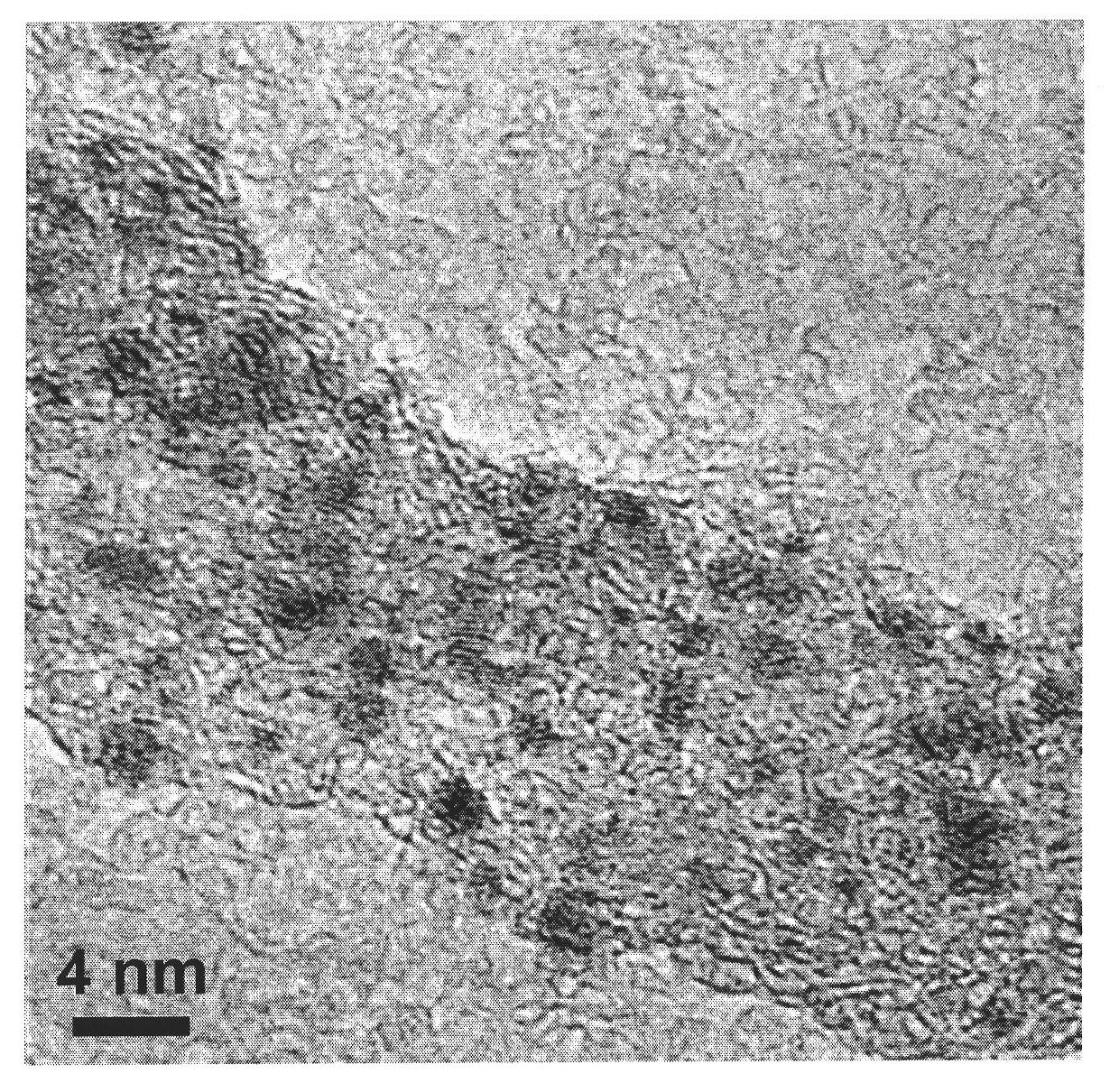

Image

Examples

Embodiment 1

[0014] Add 0.1 gram of graphite oxide into 100 milliliters of water, ultrasonically disperse for 2 hours, and form a single layer of uniformly dispersed graphene oxide colloid with a mass concentration of 1 mg / ml, and then add 0.4 mol / L concentration of Sodium hydroxide solution 1ml; Add 0.06 gram of aqueous ruthenium trichloride to 10ml water to form a ruthenium trichloride solution with a mass concentration of 6mg / ml; add all the graphene oxide colloids after adjusting the pH value to the trichlorohydrin In the ruthenium chloride solution, add 2ml of sodium hydroxide solution with a concentration of 0.4mol / L to the ruthenium trichloride mixed solution containing graphene oxide colloid, adjust the pH to 7, and then pour it into a hydrothermal kettle. heat preservation at low temperature for 6 hours, filter, wash with water, dry, and then calcinate at 150° C. for 2 hours to obtain a graphene-supported ruthenium oxide electrode material.

Embodiment 2

[0016] Add 0.1 gram of graphite oxide to 200 ml of water, and ultrasonically disperse for 2 hours to form a uniformly dispersed graphene oxide colloid with a mass concentration of 0.5 mg / ml, and then add a concentration of 0.4 mol / L to all the graphene oxide colloids 1 ml of sodium hydroxide solution; 0.06 gram of aqueous ruthenium trichloride was added to 10 ml of water to form a ruthenium trichloride solution with a mass concentration of 6 mg / ml; all the graphene oxide colloids after adjusting the pH value were added dropwise to three In the ruthenium chloride solution, add 2ml of sodium hydroxide solution with a concentration of 0.4mol / L to the ruthenium trichloride mixed solution containing graphene oxide colloid, adjust the pH to 7 and pour it into a hydrothermal kettle. heat preservation at low temperature for 6 hours, filter, wash with water, dry, and then calcinate at 150° C. for 2 hours to obtain a graphene-supported ruthenium oxide electrode material.

Embodiment 3

[0018] Add 0.1 gram of graphite oxide to 400 ml of water, and ultrasonically disperse for 2 hours to form a uniformly dispersed graphene oxide colloid with a mass concentration of 0.25 mg / ml, and then add a concentration of 0.4 mol / L to all the graphene oxide colloids 1 ml of sodium hydroxide solution; 0.06 gram of aqueous ruthenium trichloride was added to 10 ml of water to form a ruthenium trichloride solution with a mass concentration of 6 mg / ml; all the graphene oxide colloids after adjusting the pH value were added dropwise to three In the ruthenium chloride solution, add 2ml of sodium hydroxide solution with a concentration of 0.4mol / L to the ruthenium trichloride mixed solution containing graphene oxide colloid, adjust the pH to 7 and pour it into a hydrothermal kettle. heat preservation at low temperature for 6 hours, filter, wash with water, dry, and then calcinate at 150° C. for 2 hours to obtain a graphene-supported ruthenium oxide electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com