Preparation of ruthenium trichloride

A technology of ruthenium trichloride and ruthenium powder, applied in the field of preparing ruthenium trichloride, can solve problems such as the preparation method of ruthenium trichloride disclosed in few documents, and achieve the effects of high yield, effective preparation and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

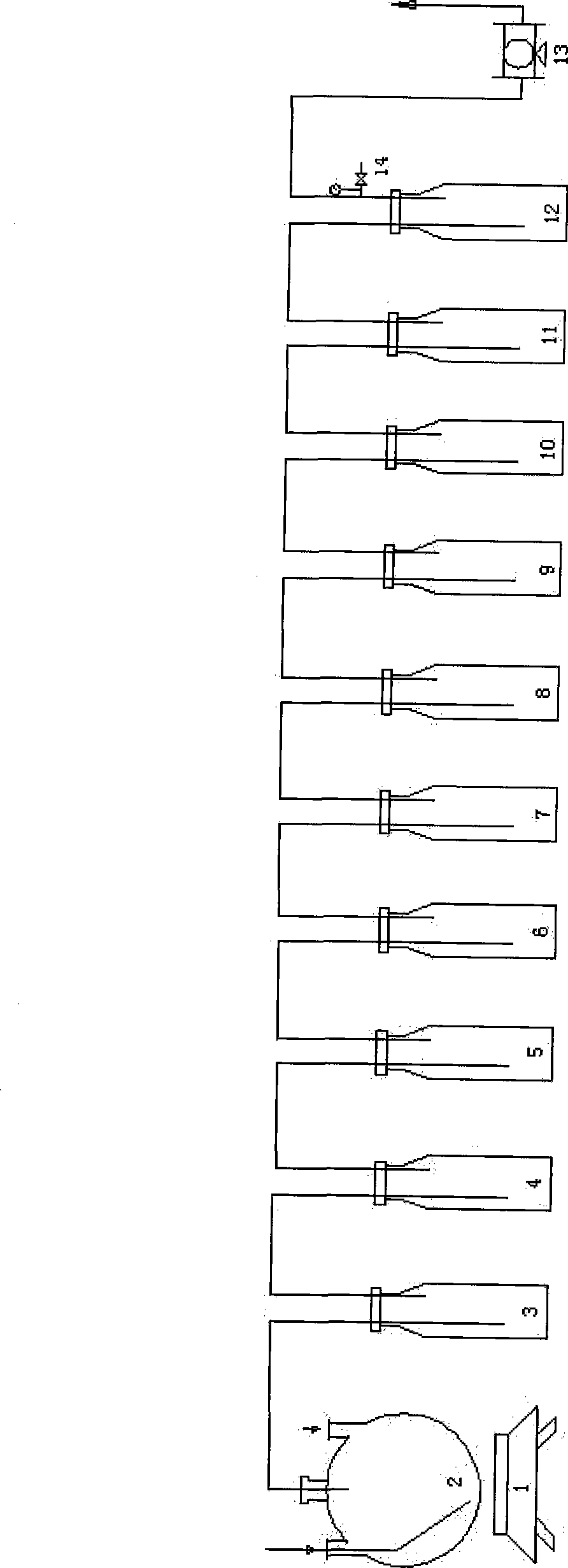

[0029] Get 10 grams of ruthenium powder and put it into the reactor 2, add 5N hydrochloric acid into the absorption bottle 4-9, and add 10% by weight sodium hydroxide solution into the absorption bottle 10-11. First check whether the whole system is normal: reactor 2, empty bottle 3, absorption bottle 4-11, buffer bottle 12, vacuum pump 13. Then start the vacuum pump 13, close the vent valve 14, check whether each absorption bottle is bubbling, and adjust the vacuum degree to reach 100mmHg.

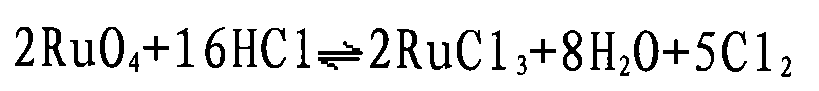

[0030] Add 500 milliliters of sodium hypochlorite solution in reactor 2, start heating with electric furnace 1, keep the temperature of the reactor at 50°C, the solution in the reactor is brownish black, after reacting for 30 minutes, slowly add 9N H 2 SO 4 The solution is in reactor 2 (feed from the bottom), and the color of the solution becomes lighter, accompanied by a large amount of golden yellow RuO 4 Gas escapes, stop adding H at this time 2 SO 4 , to be RuO 4 After steaming, ...

Embodiment 2

[0033] Get 8 grams of ruthenium powder and drop into reactor 2, add 6N hydrochloric acid and 0.5% by weight ethanol (based on the total weight of hydrochloric acid and ethanol) in the absorption bottle 4-9, add 15% by weight sodium hydroxide in the absorption bottle 10-11 solution. First check whether the whole system is normal: reactor 2, empty bottle 3, absorption bottle 4-11, buffer bottle 12, vacuum pump 13. Then start the vacuum pump 13, close the vent valve 14, check whether each absorption bottle is bubbling, and adjust the vacuum degree to reach 80mmHg.

[0034] Add 600 milliliters of sodium hypochlorite solution in reactor 2, start heating with electric furnace 1, keep the temperature of the reactor at 60°C, the solution in the reactor is brownish black, after reacting for 40 minutes, slowly add 8N H 2 SO 4 The solution is in reactor 2 (feed from the bottom), and the color of the solution becomes lighter, accompanied by a large amount of golden yellow RuO 4 Gas esc...

Embodiment 3

[0037] Get 12 grams of ruthenium powder and drop into reactor 2, add 7N hydrochloric acid and 1.0% by weight ethanol (based on the total weight of hydrochloric acid and ethanol) in the absorption bottle 4-9, add 12% by weight of hydroxide in the absorption bottle 10-11 sodium solution. First check whether the whole system is normal: reactor 2, empty bottle 3, absorption bottle 4-11, buffer bottle 12, vacuum pump 13. Then start the vacuum pump 13, close the vent valve 14, check whether each absorption bottle is bubbling, and adjust the vacuum degree to reach 130mmHg.

[0038] Add 1000 ml of sodium hypochlorite solution in reactor 2, start heating with electric furnace 1, keep the temperature of the reactor at 70°C, the solution in the reactor is brownish black, after reacting for 50 minutes, slowly add 10N H 2 SO 4 The solution is in reactor 2 (feed from the bottom), and the color of the solution becomes lighter, accompanied by a large amount of golden yellow RuO 4 Gas escap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com