Method for preparing ruthenium trichloride from coarse ruthenium powder

A technology of ruthenium trichloride and ruthenium powder, which is applied in the field of preparing ruthenium trichloride from coarse ruthenium powder, can solve the problems of many times of distillation and long time, difficult control of product quality, low product yield, etc. The effect of easy quality control and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

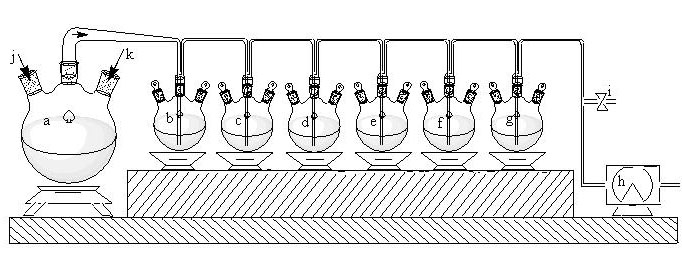

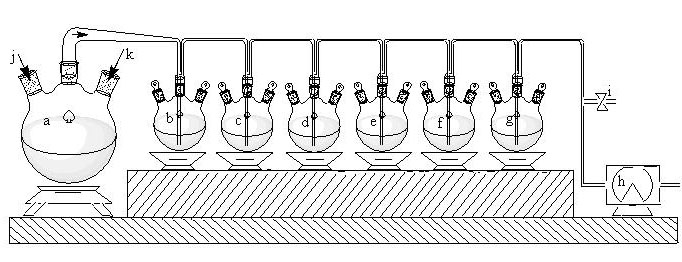

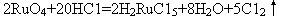

[0029] Take 50g of coarse ruthenium powder (60.56% ruthenium content) in one or two mixtures of dilute sulfuric acid, ammonium chloride, hydrochloric acid or ammonia water medium with a mass fraction of 1-15%, and activate it to 200 After -800 mesh, filter and wash until neutral, put it into reactor a, add 0.5L NaOH solution with a mass fraction of 10–40%, add 2L of dilute sulfuric acid, dilute nitric acid or deionized water to the impurity removal bottles b and c One or several substances, the mass fraction of dilute sulfuric acid and dilute nitric acid solution is 0.1–5%, to Add 2.5L of 2–10mol / L hydrochloric acid and one or two mixtures of methanol, ethanol, n-propanol, and isopropanol to absorption bottles d, e, and f to keep the mass fraction at 0.01–6%. Add 3L of 5–10% NaOH solution to g. First turn on the vacuum pump h, close the purge valve i, check the airtightness of the entire preparation system, and adjust the negative pressure to 0.01–0.1MPa.

[0030] After fee...

Embodiment 2

[0032] Take 50g of coarse ruthenium powder (the ruthenium content is 76.50%) in one or two mixtures of dilute sulfuric acid, ammonium chloride, hydrochloric acid or ammonia water medium with a mass fraction of 1-15%, and activate it to 200 After -800 mesh, filter and wash until neutral, put it into reactor a, add 0.8L NaOH solution with a mass fraction of 10–40%, add 2L of dilute sulfuric acid, dilute nitric acid or deionized water to the impurity removal bottles b and c One or several substances, the mass fraction of dilute sulfuric acid and dilute nitric acid solution is 0.1–5%, to Add 2.5L of 2–10mol / L hydrochloric acid and one or two mixtures of methanol, ethanol, n-propanol, and isopropanol to absorption bottles d, e, and f to keep the mass fraction at 0.01–6%. Add 3L of 5–10% NaOH solution to g. First turn on the vacuum pump h, close the purge valve i, check the airtightness of the entire preparation system, and adjust the negative pressure to 0.01–0.1MPa.

[0033] Af...

Embodiment 3

[0035] Take 50g of coarse ruthenium powder (the ruthenium content is 90.16%) in one or two mixtures of dilute sulfuric acid, ammonium chloride, hydrochloric acid or ammonia water medium with a mass fraction of 1-15%, and activate it to 200 After -800 mesh, filter and wash until neutral, put it into reactor a, and add 1L of NaOH solution with a mass fraction of 10–40%, add 2L of dilute sulfuric acid, dilute nitric acid or deionized water to the impurity removal bottles b and c One or more substances, the mass fraction of dilute sulfuric acid and dilute nitric acid solution is 0.1–5%, to Add 2.5L of 2–10mol / L hydrochloric acid and one or two mixtures of methanol, ethanol, n-propanol, and isopropanol to absorption bottles d, e, and f to keep the mass fraction at 0.01–6%. Add 3L of 5–10% NaOH solution to g. First turn on the vacuum pump h, close the purge valve i, check the airtightness of the entire preparation system, and adjust the negative pressure to 0.01–0.1MPa.

[0036] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com