Preparation method of catalyst for hydrogen production based on Ru/r-CoP composite material hydrolysis

A composite material, hydrogen production technology by hydrolysis, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve the problems of hydrogen evolution rate restriction and slow hydrogen evolution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

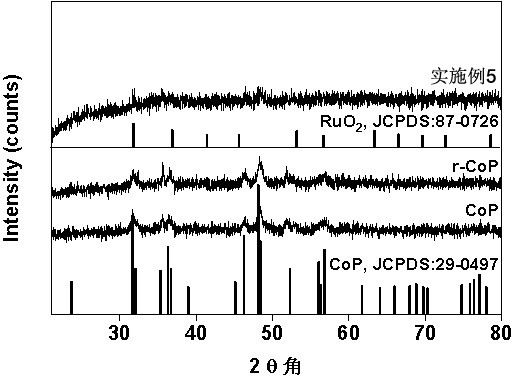

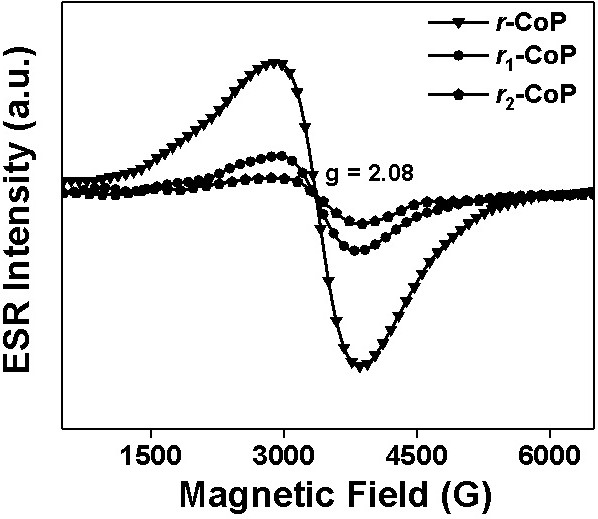

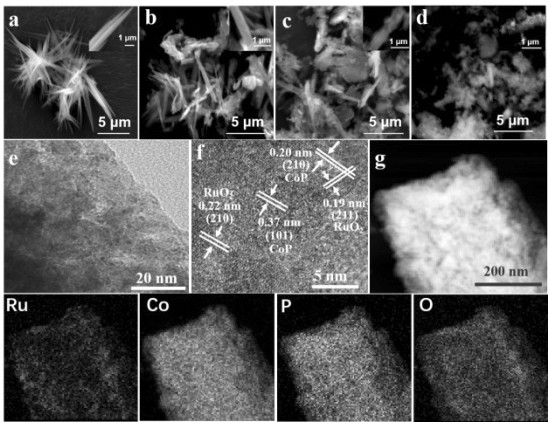

[0019] Below will combine the appended in the embodiment of the present invention Figure 1 to Figure 6 , to describe the technical solutions in the embodiments of the present invention.

[0020] One, embodiment 1,2,3,4,5,6

[0021] Step (1), preparation of cobalt-based precursor (CoOOH): 0.71 g of cobalt acetate tetrahydrate and 0.82 g of sodium acetate trihydrate were ultrasonically dissolved in 60 mL of deionized water. Cobalt-based precursors were obtained by hydrothermal reaction at 120 °C. The product was collected by centrifugation, washed several times with deionized water, and dried in a blast drying oven for 12 hours.

[0022] Step (2), preparation of cobalt phosphide (CoP) precursor: Weigh 60 mg of the cobalt-based precursor in step (1) and place it in a quartz porcelain boat, and add 1.0 g of sodium hypophosphite to another quartz boat. The sample was kept in an inert gas atmosphere in the same tube furnace at 350°C for 2 hours, and the product was obtained afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com