New method for preparing ruthenium nitrosylnitrate solid

A technology of ruthenium nitrosyl nitrate and sodium nitrite, which is applied in the field of preparing solid ruthenium nitrosyl nitrate, can solve the problems of inconvenient use and transportation, and achieve the effect of simple operation and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

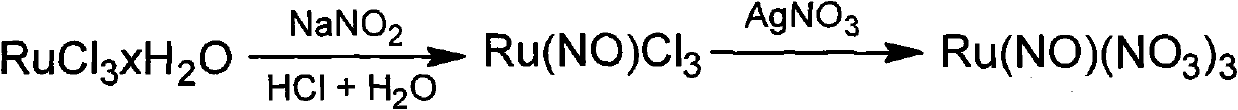

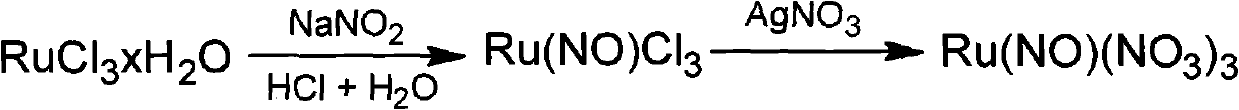

Method used

Image

Examples

Embodiment Construction

[0009] (1) Nitrosyl ruthenium chloride Ru(NO)Cl 3 preparation of

[0010] Dissolve 150g of ruthenium trichloride hydrate in 1050mL of 1mol / L hydrochloric acid solution, heat to reflux, add 750mL of an aqueous solution containing 116g of sodium nitrite dropwise, along with reddish-brown gas NO 2 The release of the solution changed from deep red to deep purple, and the reaction was continued for 4 hours, and the water was distilled off to obtain a solid mixture. Dissolve Ru(NO)Cl in absolute ethanol 3 , filtered to remove NaCl insoluble in ethanol, and the filtrate was evaporated to recover ethanol to obtain ruthenium nitrosyl chloride Ru(NO)Cl 3 146.5 grams.

[0011] (2) Ru(NO)(NO 3 ) 3 preparation of

[0012] Get 148.5 grams of ruthenium nitrosyl chloride, be dissolved in 1000ml of water, add the silver solution that contains 365g of nitric acid, stir, heat and reflux reaction for 5 hours, the reaction solution is visually inspected with NaCl for no free silver ions. Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com