Reverse micelle method for preparing platinum ruthenium/carbon catalyst

A technology of carbon catalyst and reverse micelles, which is applied in the field of reverse micelles for the preparation of carbon-supported platinum-ruthenium catalysts, which can solve problems such as uneven particle size, poor particle dispersion, and harsh reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

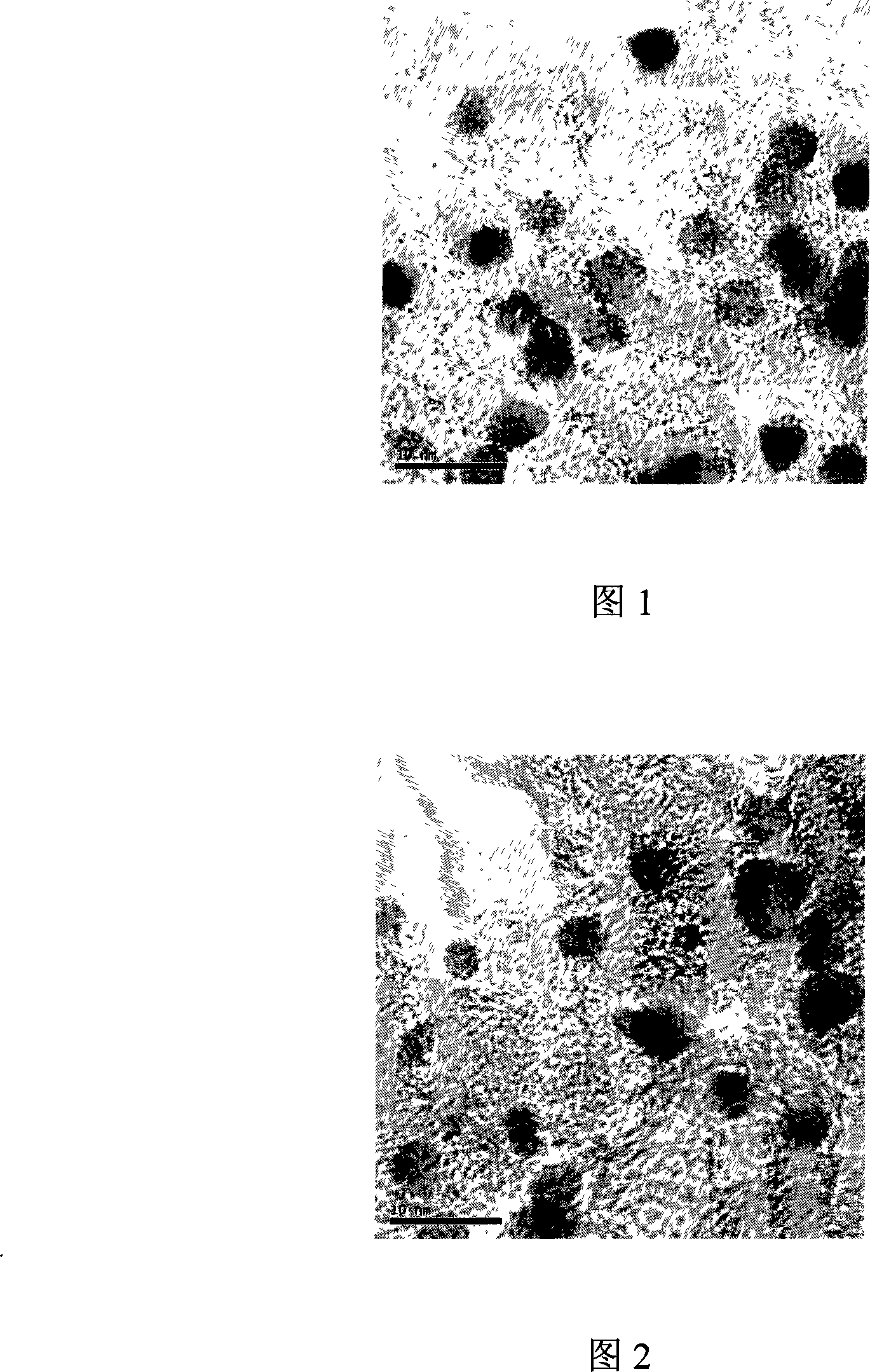

Image

Examples

Embodiment 1

[0019] ① Configure chloroplatinic acid (H 2 PtCl 6 ) aqueous solution, its concentration is 0.0386mol / L; configure ruthenium trichloride (RuCl 6 ) aqueous solution with a concentration of 0.0765mol / L.

[0020] ② Prepare a mixture of cyclohexane, sodium lauryl sulfate and n-octanol. The mass ratio of sodium lauryl sulfate to cyclohexane is 0.115, and the mass ratio to n-octanol is 0.7.

[0021] ③Take 100ml of the mixed solution of the above step ②, the molar ratio of water to surfactant is 7, ultrasonically oscillate for 20 minutes, then add 2.19ml of chloroplatinic acid and 1.1ml of ruthenium trichloride aqueous solution dropwise. Sonicate for 30 minutes to form a transparent reverse micellar system.

[0022] ④ Add 100 mg of carbon black Vulcan XC-72 carbon black to the system described in the above step ③, and oscillate ultrasonically for 20 minutes.

[0023] 5. Add 4.5ml of 0.2mol / L potassium borohydride aqueous solution (6 times the theoretical value, 2 times the volum...

Embodiment 2

[0029] ① Configure chloroplatinic acid (H 2 PtCl 6 ) aqueous solution, its concentration is 0.1mol / L; configure ruthenium trichloride (RuCl 3 ) aqueous solution, the concentration of which is 0.04mol / L.

[0030] ② Prepare a mixture of cyclohexane, sodium lauryl sulfate and n-octanol. The mass ratio of sodium lauryl sulfate to cyclohexane is 0.078, and the mass ratio to n-octanol is 1.0.

[0031] ③Take 130ml of the mixed solution of the above step ②, the molar ratio of water to surfactant is 11, ultrasonically oscillate for 15 minutes, and then add 1.45ml of chloroplatinic acid and 3.61ml of ruthenium trichloride aqueous solution dropwise. Sonicate for 60 minutes to form a transparent reverse micellar system.

[0032] ④ Add 100 mg of carbon black Vulcan XC-72 carbon black to the system described in the above step ③, and oscillate ultrasonically for 30 minutes.

[0033] 5. Add 2.53ml of 1.5mol / L sodium borohydride aqueous solution (15 times the theoretical value, 0.5 times ...

Embodiment 3

[0039] ① Configure chloroplatinic acid (H 2 PtCl 6 ) aqueous solution, its concentration is 0.02mol / L; configure ruthenium trichloride (RuCl 3 ) aqueous solution, the concentration range of which is 0.20mol / L.

[0040] ② Prepare a mixture of cyclohexane, sodium lauryl sulfate and n-octanol. The mass ratio of sodium lauryl sulfate to cyclohexane is 0.15, and the mass ratio to n-octanol is 1.2.

[0041] ③Take 150ml of the mixed solution of the above step ②, the molar ratio of water to surfactant is 4.2, ultrasonically oscillate for 40 minutes, then add 5.10ml of chloroplatinic acid and 0.25ml of ruthenium trichloride aqueous solution dropwise. Sonicate for 20 minutes to form a transparent reverse micellar system.

[0042] ④ Add 100 mg of carbon black Vulcan XC-72 carbon black to the system described in the above step ③, and oscillate ultrasonically for 60 minutes.

[0043] 5. Add 8.0ml of 0.053mol / L potassium borohydride aqueous solution (3 times the theoretical value, 1.5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com