Catalyst for electrocatalytic reduction of nitrate as well as preparation method and application thereof

A nitrate, electrocatalysis technology, applied in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high catalyst cost and low catalytic performance Ru, and achieve improved catalytic performance, high current The effect of density, preparation method and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the embodiments of the present invention.

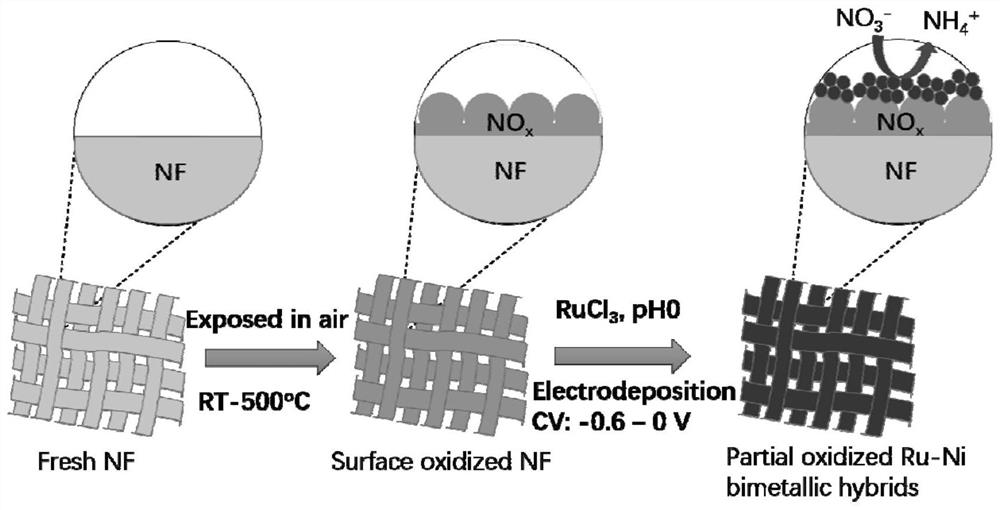

[0029] Such as Figure 1 to Figure 6 Shown, a kind of catalyst preparation method of electrocatalytic reduction of nitrate comprises the steps:

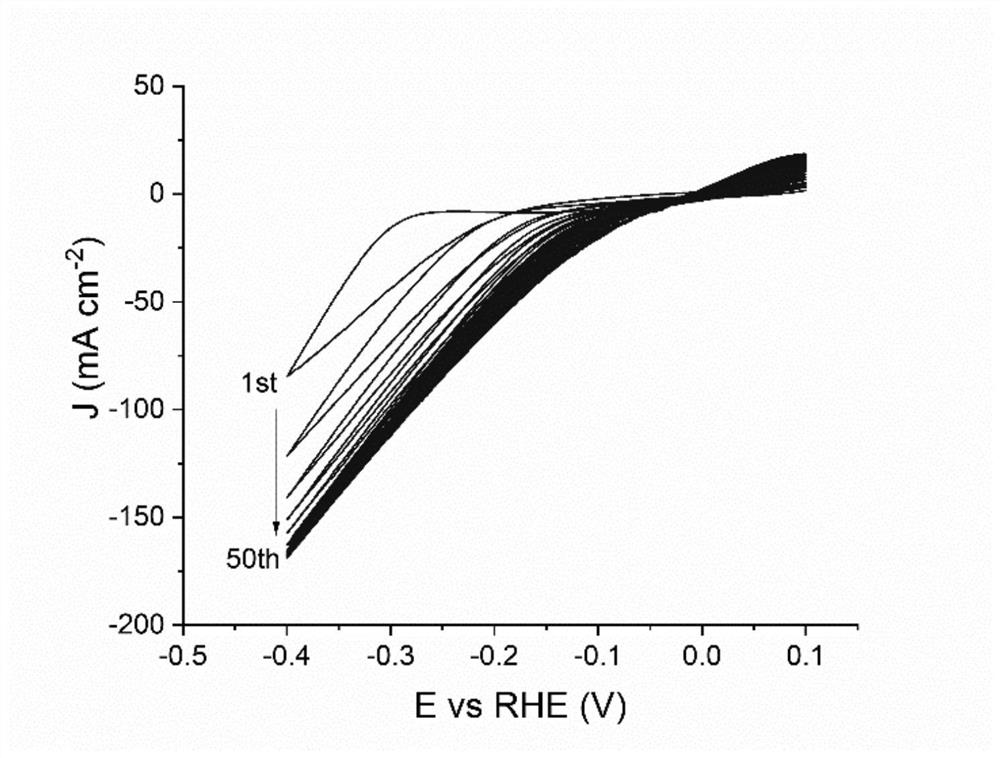

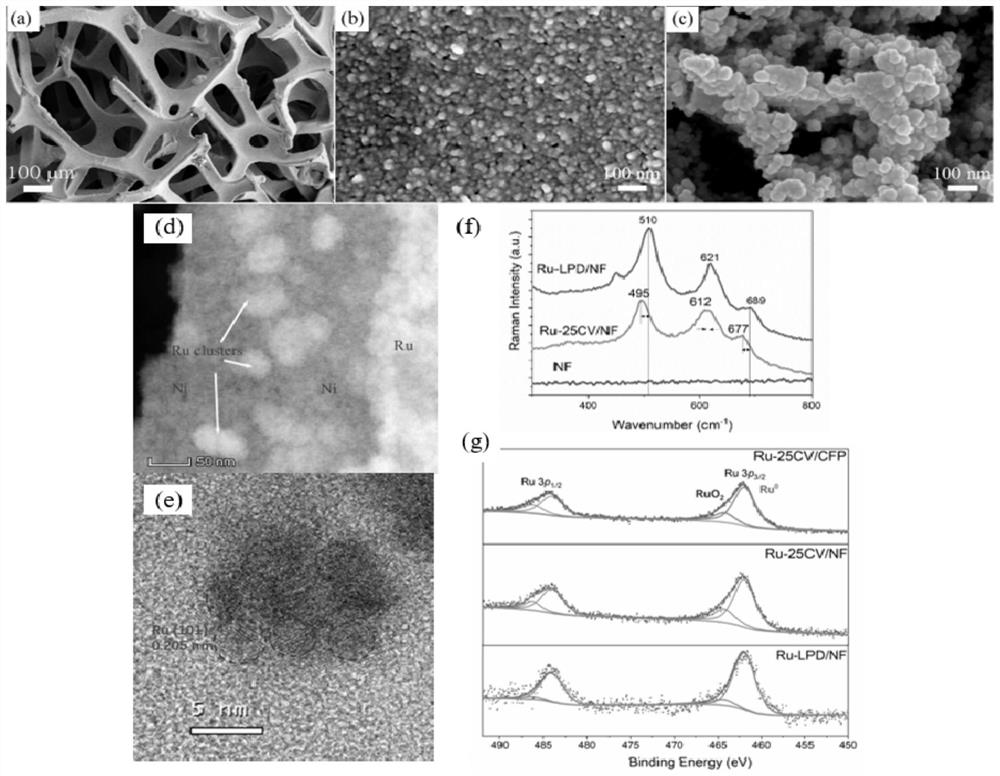

[0030] Using nickel foam as a substrate, a nickel oxide layer is formed on the surface of nickel foam to obtain a composite; using ruthenium trichloride solution, ruthenium nanoparticles are deposited on the composite by electrochemical cyclic voltammetry to obtain a Ni-Ru composite catalyst. Nickel foam is used as a substrate to provide a high electrochemically active surface area for electrochemical reactions; an oxide layer is introduced on the surface of nickel foam to effectively improve the catalytic performance of the catalyst for nitrate reduction.

[0031] In the step of using nickel foam as a substrate to form a nickel oxide layer on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com