Thin-wall ceramic membrane tube applied to membrane absorption process, membrane adsorption method and application thereof

A ceramic membrane tube and membrane absorption technology, which is applied in the field of membrane absorption, can solve the problems of increased filtration resistance and affecting absorption efficiency, etc., and achieve the effects of improving absorption effect, improving absorption efficiency, and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The field of application of the ceramic membrane tube involved in the present invention is mainly through the membrane absorption and separation of the components to be absorbed in the gas by the absorbing liquid, for example: for the acid gas (SO x , CO x , NO x etc.) for absorption, the gas moves outside the ceramic membrane tube, while the absorption liquid flows inside the ceramic membrane tube, the components to be absorbed in the gas enter the inner cavity of the tube through the pores of the ceramic membrane tube, and the components are absorbed by the absorption liquid . In addition, absorbents that can react with the components to be absorbed can also be added to the absorption liquid to improve the absorption efficiency, such as NaOH, KOH, NH 3 Wait. If it is for alkaline gas NH 3 When absorbing, water can be used as the absorption liquid, and hydrochloric acid, sulfuric acid, etc. can be used as the absorbent.

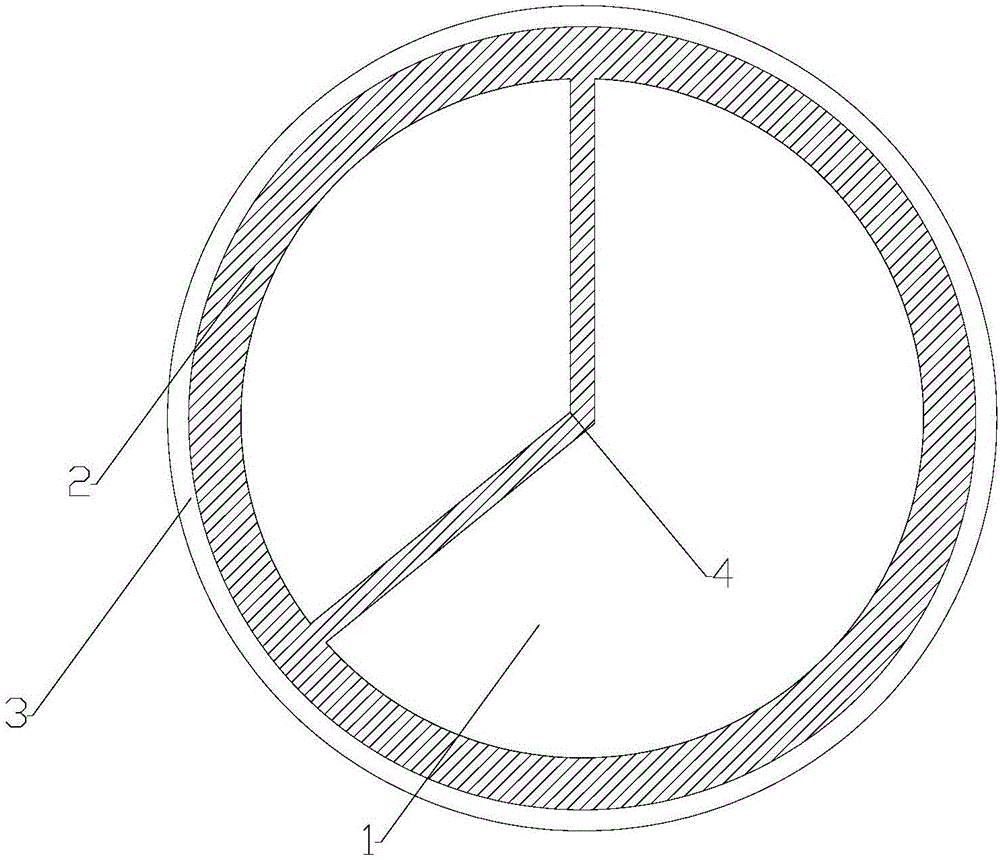

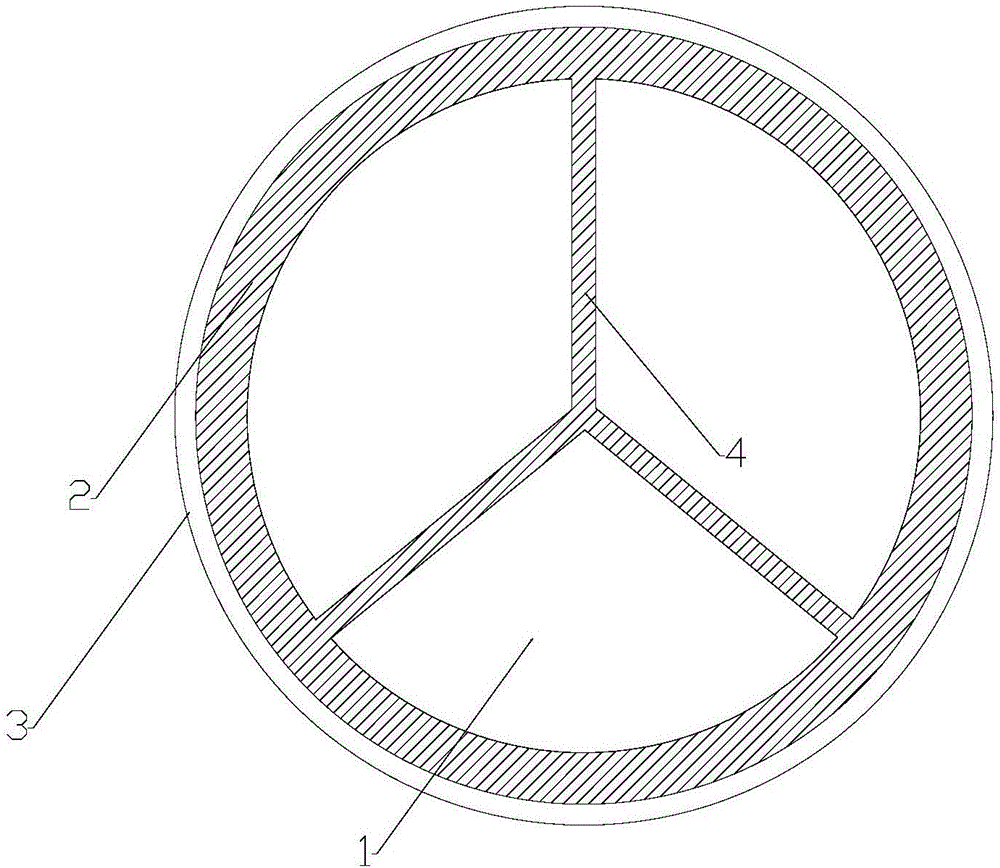

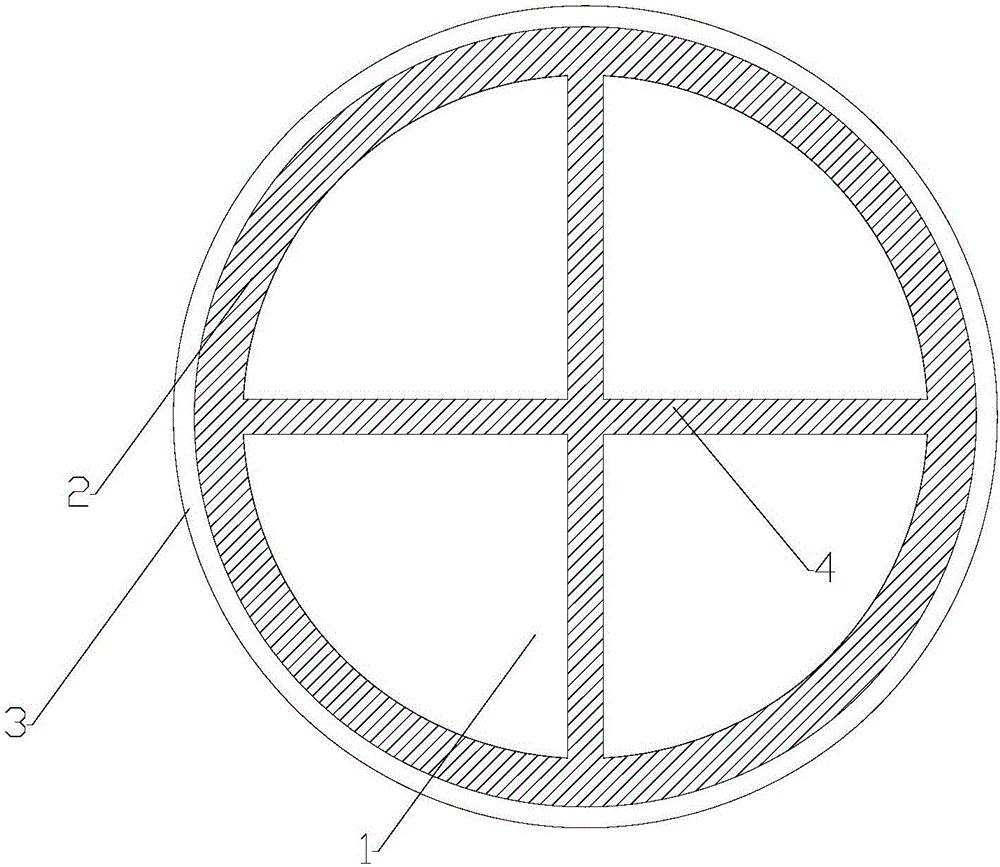

[0038] The structure of the ceramic membra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Equivalent diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com