Purification method of mixed water body with algae and silt

A water and sediment technology, applied in the field of polluted water purification, can solve the problems of high total cost of water treatment, large equipment investment, long process flow, etc. Simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

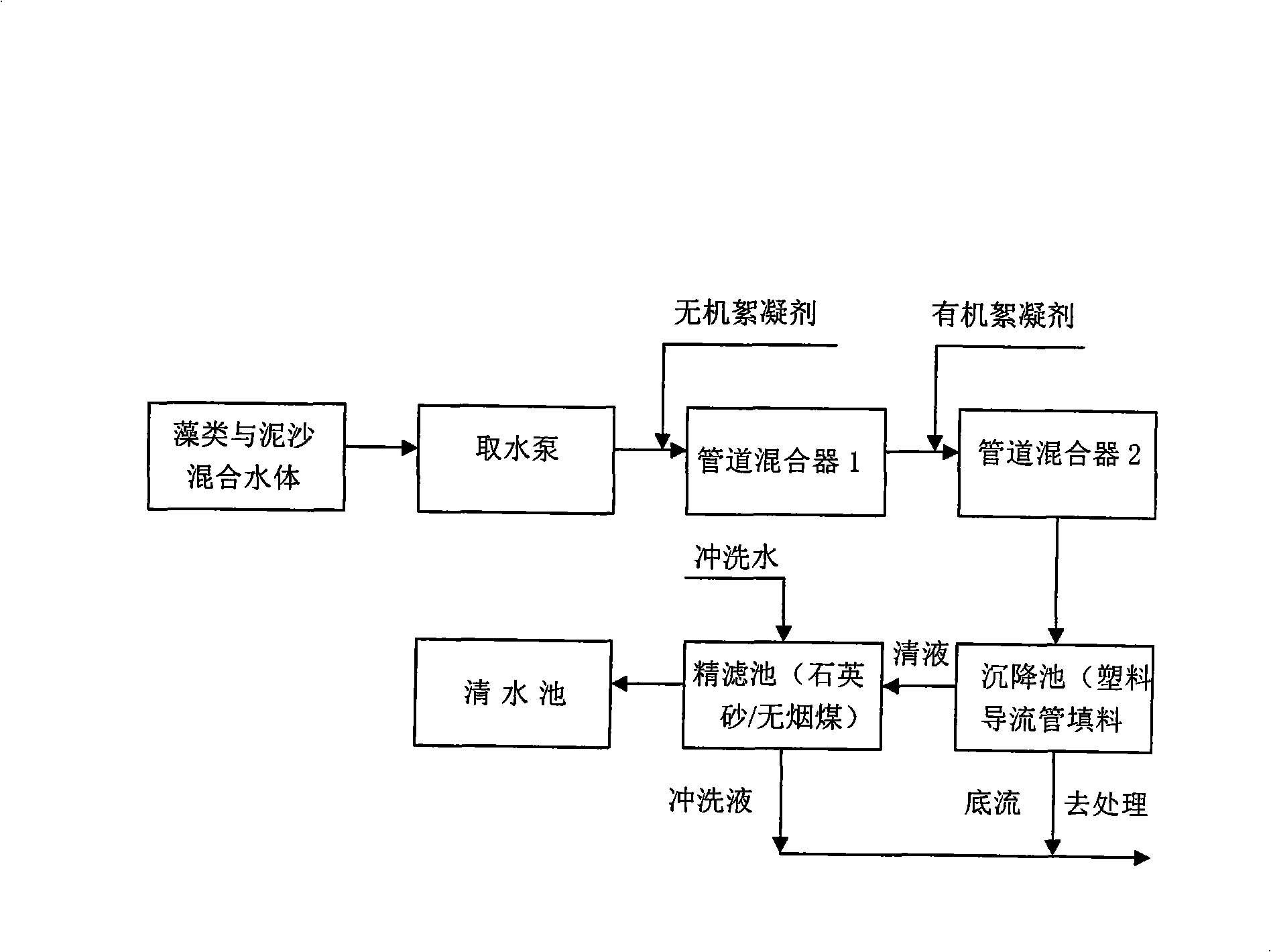

Embodiment 1

[0025] The Dianchi Lake water containing 60mg / L of suspended solids (mainly algae and less sediment) in the dry season is treated. Firstly add 20ppm polyaluminum ferric chloride to the inlet water body of the pipeline mixer 1, mix evenly through the pipeline mixer 1, flocculation occurs, and many small flocculation clumps (about 3-5mm in diameter) are produced. Then add 2.5ppm of polyacrylamide into the inlet water body of the pipeline mixer 2, mix evenly through the pipeline mixer 2, flocculation occurs, and many large flocculation clumps (about 10-50mm in diameter) are produced. The coagulated water coming out of the pipeline mixer 2 enters the settling tank through a pipeline about 4m long, and stays and settles for about 31min. The material enters the bottom flow of the sedimentation tank, and is discharged after treatment; the overflow water of the sedimentation tank enters the fine filter tank, and is filtered through the quartz sand layer and anthracite layer to obtain ...

Embodiment 2~12

[0027]The technological process of these 11 embodiments is the same as that of embodiment 1, except that the types of inorganic flocculants added to the inlet water of pipeline mixer 1 are polyaluminum silicate, polysilicate iron, polyaluminum iron iron, polysilicon One of aluminum chloride, polyaluminum chloride, polyferric sulfate, polyferric chloride, ferric chloride, basic aluminum chloride, ferrous sulfate or aluminum sulfate, or a mixture thereof. The organic flocculant added to the inlet water body of the pipeline mixer 2 is polyacrylamide, chitosan or modified polyacrylamide.

Embodiment 13

[0029] The Dianchi Lake water containing 100mg / L of suspended solids (mainly algae and sediment) during the flood period will be treated. First, add 30ppm polyaluminum iron silicate into the inlet water body of the pipeline mixer 1, mix evenly through the pipeline mixer 1, flocculation occurs, and many small flocculation clumps (about 3-5mm in diameter) are produced. Add 4ppm of polyacrylamide to the inlet water body of the pipeline mixer 2, mix evenly through the pipeline mixer 2, flocculation occurs, and many large flocculation clumps (about 10-50mm in diameter) are produced. The coagulated water coming out of the pipeline mixer 2 enters the settling tank through a pipeline about 4m long, and stays and settles for about 26 minutes. The material enters the bottom flow of the sedimentation tank, and is discharged after treatment; the overflow water of the sedimentation tank enters the fine filter tank, and is filtered through the quartz sand layer and anthracite layer to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com