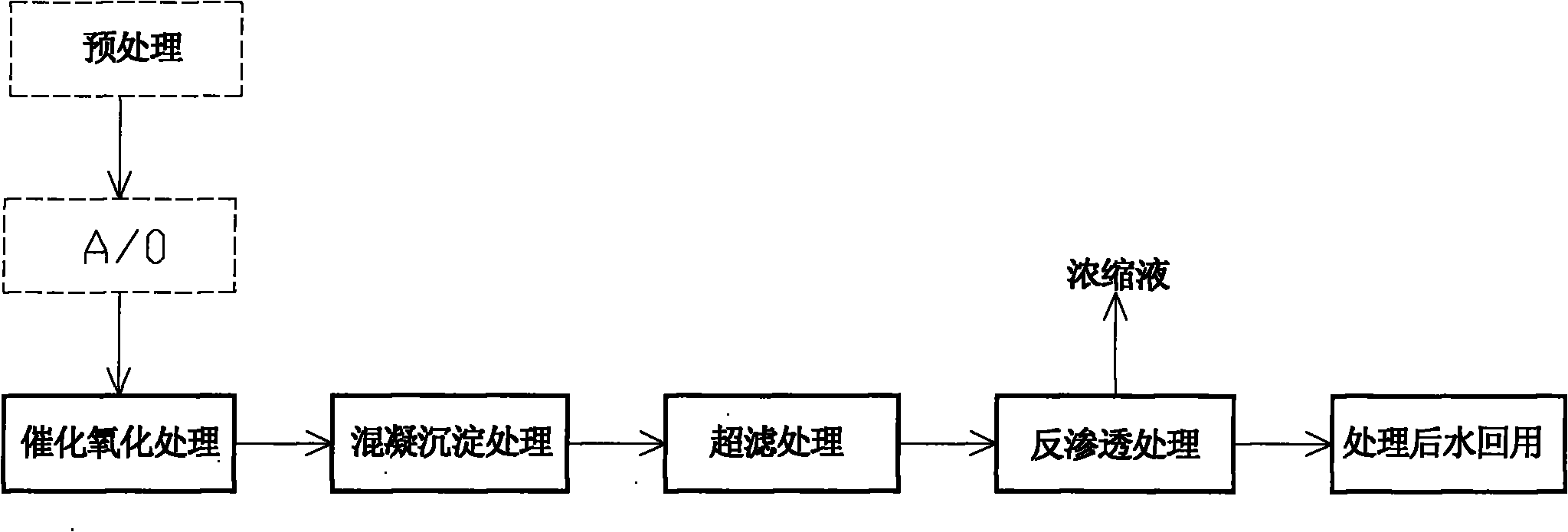

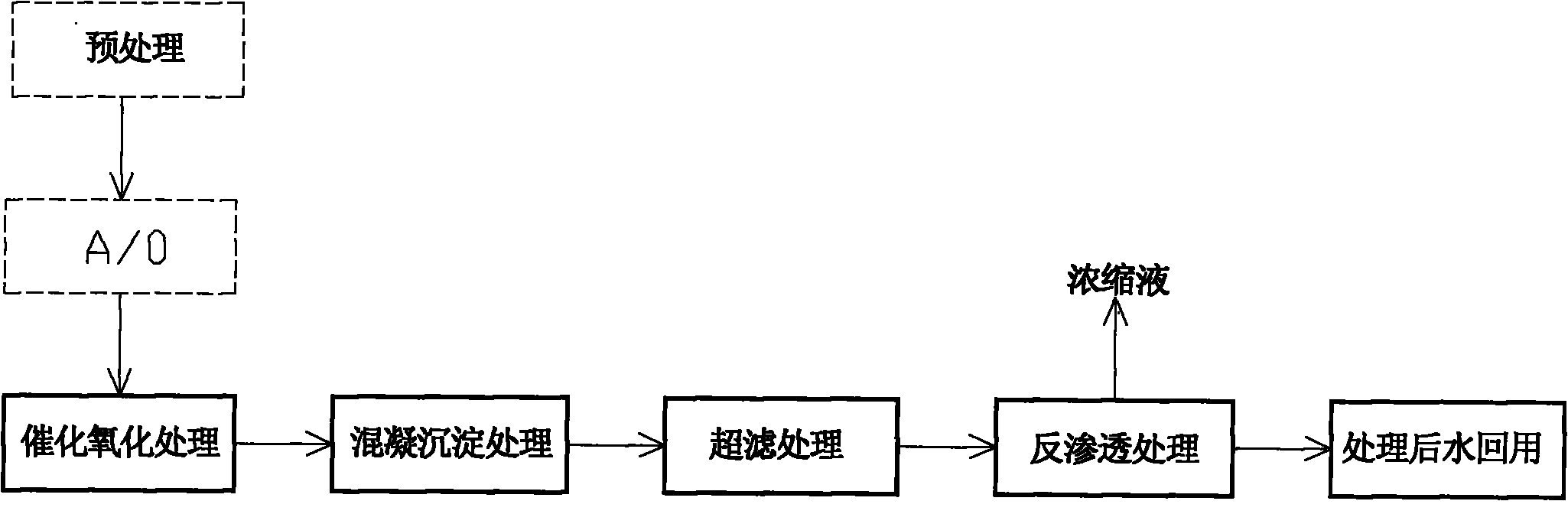

Technology for deeply processing coking wastewater through combining catalytic oxidation method and membrane separation technique

A technology for catalytic oxidation and coking wastewater, which is applied in the direction of oxidized water/sewage treatment, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc. To achieve the effect of stable treatment effect, less one-time investment and significant social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0050] Example 1: For a coking plant with an annual output of 1.5 million tons of coke, 76m of coking wastewater is produced 3 / h, circulating water sewage 52m 3 / h, the total treated water volume is 128m 3 / h. The biochemical system adopts A / O internal circulation biological denitrification treatment technology, and the water output of biochemical treatment is 128m 3 / h, water quality: CODCr≤150mg / L, NH3 -N ≤ 5mg / L, SS ≤ 5mg / L, phenol ≤ 0.5mg / L, cyanide ≤ 0.5mg / L, PH ~ 7, reaching the national comprehensive discharge secondary standard. Then these biochemical effluents undergo a series of treatment processes such as catalytic oxidation, coagulation sedimentation, and ultrafiltration membranes to remove COD, suspended solids and other pollutants that are difficult to biodegrade in the water. Water quality indicators: CODcr≤80mg / L, NH 3 -N≤5mg / L, suspended matter SS3 -N≤5mg / L, oil3 At the same time, it meets the requirements of "Urban Sewage Recycling-Industrial Water Qualit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com