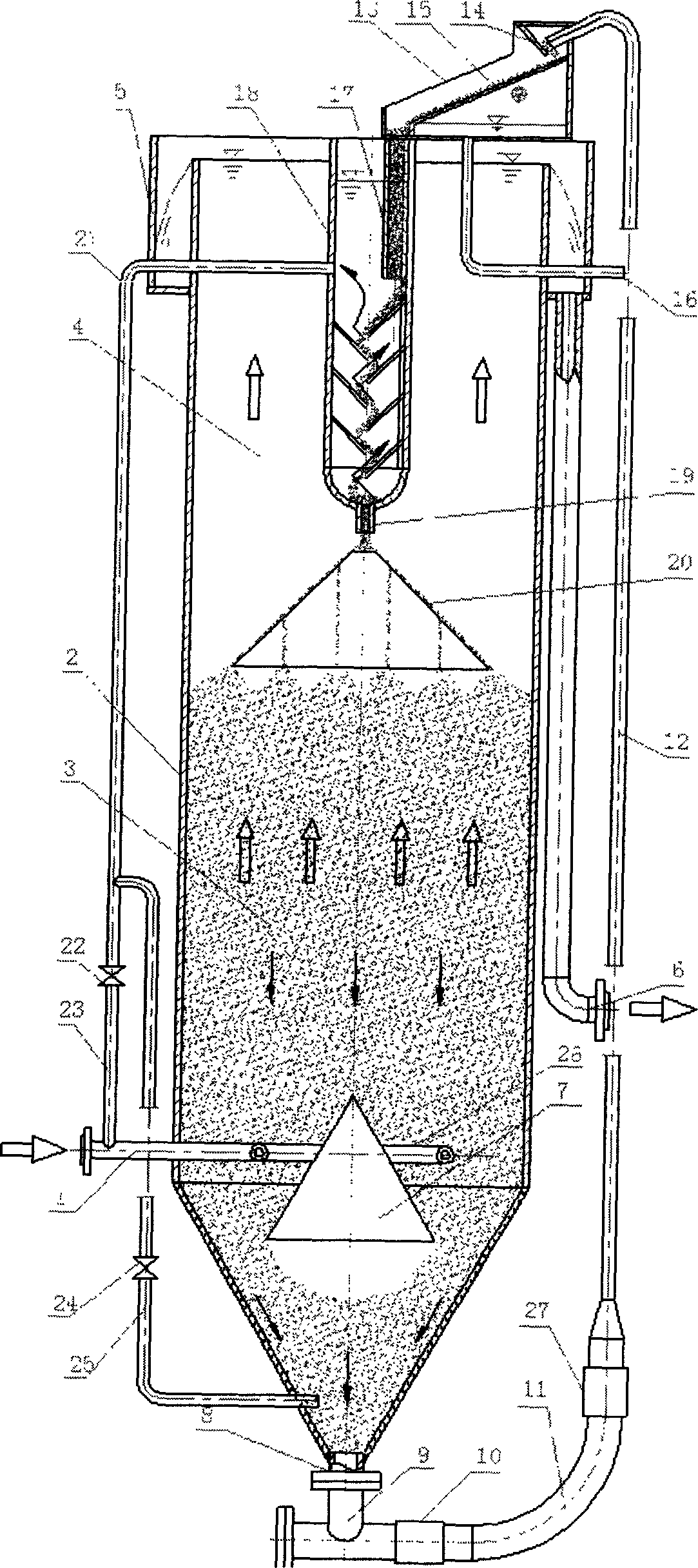

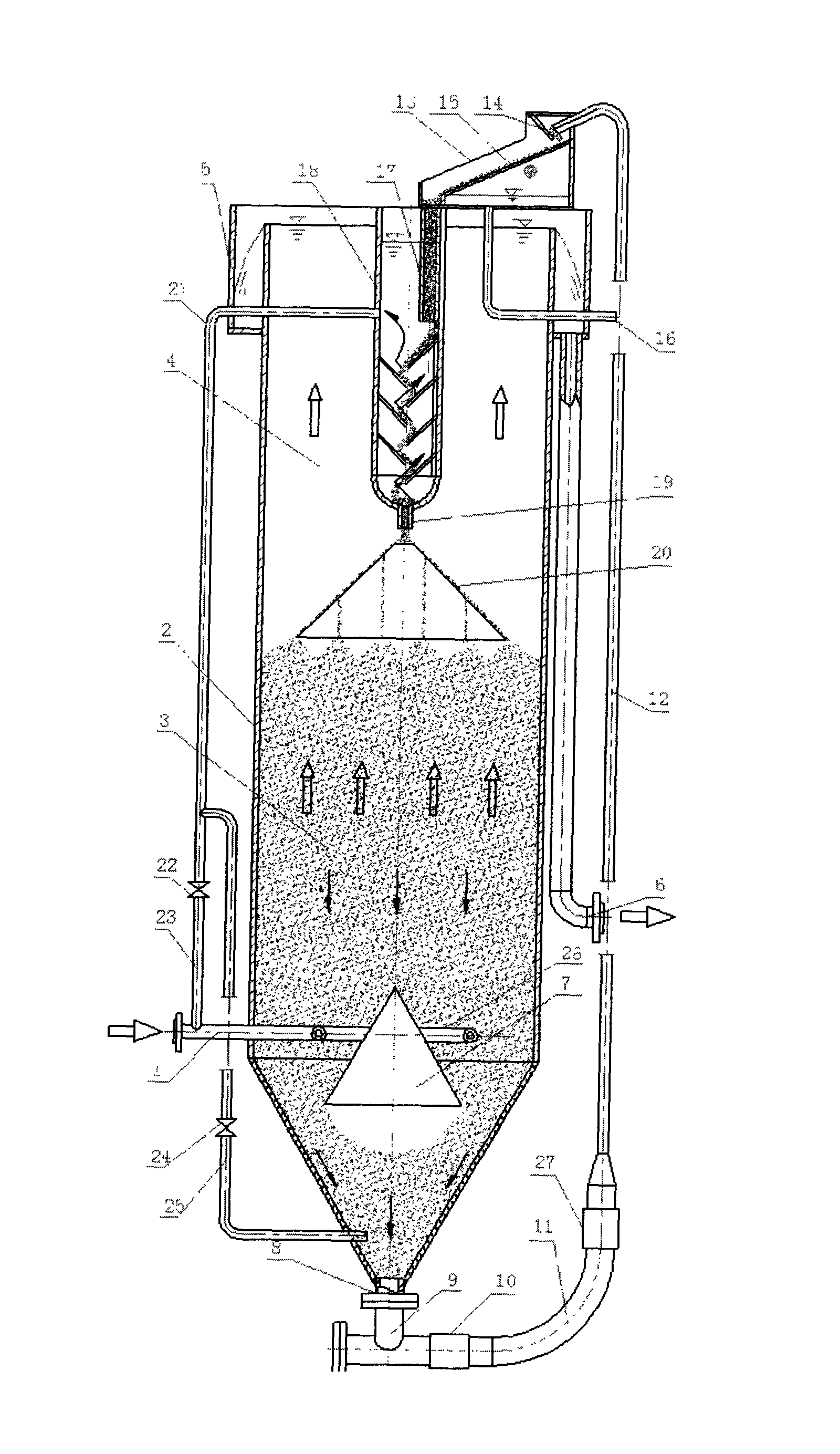

Device for removing suspended matter in water

A technology for suspended solids and water removal, applied in the directions of loose filter material filters, filtration separation, gravity filters, etc. The effect of reduced concentration, high suspended solids concentration, and stable washing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The effluent after biochemical treatment of an oil refinery has a concentration of suspended solids of 90 mg / l and a turbidity of 60 degrees. After being treated by the filter equipment of the present invention, the concentration of suspended solids in the filtered water is reduced to 4 mg / l, the turbidity is 3 degrees, the amount of concentrated sewage discharged outside is 1.5% of the influent, and the concentration of suspended solids is 5680 mg / l. And the method of adopting the filter material scrubber to discharge the concentrated sewage keeps the concentration of suspended solids in the filtered water at 4mg / l, the amount of discharged sewage should reach 4% of the influent, and the concentration of suspended solids in the discharged water should be 2120mg / l. If the efflux is reduced to 1.5%, the suspended solids in the filtered water will increase to 15mg / l.

Embodiment 2

[0030] In the sewage of a catalyst factory, the concentration of suspended solids in the water is 130mg / l, and the turbidity is 110 degrees. The pollutants are mainly molecular sieves with fine particle diameters and silicate and other production materials. With the filtering equipment of the present invention, the concentration of suspended solids in the treated water is 4.5 mg / l, the turbidity is 2.8 degrees, the external discharge accounts for 2.5% of the treated water, and the suspended solids concentration is 5030 mg / l, which lays a good foundation for the recovery of production raw materials. Foundation. And adopt the method of filter material scrubber to discharge concentrated sewage, when keeping the concentration of suspended matter in the filtered water at 4.5mg / l, the amount of discharged sewage should reach 6% of the influent, and the concentration of suspended matter in the discharged water should be 2100mg / l. If the efflux is reduced to 2.5%, the suspended solids...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com