A wastewater desalination process with a high water yielding rate and a device thereof

A wastewater and process technology, applied in general water supply conservation, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as low water production rate, secondary pollution electrodialysis, and difficulty in adapting to wastewater treatment. , to achieve the effect of improving membrane life and high water production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

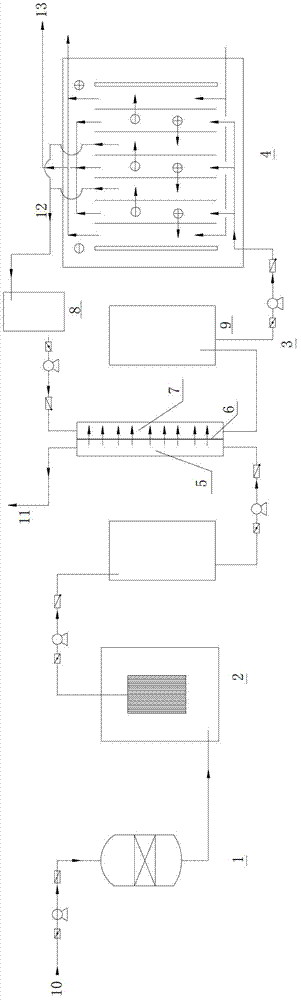

[0027] The object of advanced treatment is coking wastewater after biological treatment, and the TDS (total dissolved solids) in the wastewater is about 1000mg / L.

[0028] Wastewater 10 first enters the sand filter 1 for filtration, then enters the submerged ultrafiltration tank 2, the ultrafiltration filtration accuracy is 0.1 micron, and then enters the forward osmosis unit 3; the draw solution of the forward osmosis unit 3 adopts 30g / L chlorinated Sodium solution, after passing through the forward osmosis unit 3, the wastewater is concentrated to about 10g / L, the concentration factor is 10 times, the water production rate is 90%, the concentrated wastewater 11 is discharged or disposed of; the diluted sodium chloride solution After entering the subsequent electrodialysis unit 4 for concentration, the concentrated sodium chloride solution 12 reaching 30 g / L is returned to the forward osmosis unit 3 as a drawing solution, and the obtained pure water 13 is reused at the same ti...

Embodiment 2

[0030] The object of advanced treatment is urban wastewater after biological treatment, and the TDS (total dissolved solids) in the wastewater is about 500mg / L.

[0031] Wastewater 10 first enters sand filter 1 for filtration, then enters submerged ultrafiltration tank 2, the ultrafiltration filtration accuracy is 0.1 micron, and then enters forward osmosis unit 3; the draw solution of forward osmosis unit 3 adopts 8g / L chlorinated Sodium solution, after passing through the forward osmosis unit 3, the wastewater is concentrated to about 6g / L, the concentration factor is 12 times, and the water production rate is 92%. The concentrated wastewater 11 is discharged or disposed of; the diluted sodium chloride solution After entering the subsequent electrodialysis unit 4 for concentration, the concentrated sodium chloride solution 12 reaching 8 g / L is returned to the forward osmosis unit 3 as a drawing solution, and the obtained pure water 13 is reused at the same time.

Embodiment 3

[0033] The object of advanced treatment is the concentrated brine from the reverse osmosis desalination station, and the TDS (total dissolved solids) in the wastewater is about 8000mg / L.

[0034] The waste water 10 first enters the sand filter 1 for filtration, then enters the submerged ultrafiltration tank 2, and the ultrafiltration filtration accuracy is 0.1 micron, and then enters the forward osmosis unit 3; Sodium solution, after passing through the forward osmosis unit 3, the wastewater is concentrated to about 48g / L, the concentration factor is 6 times, and the water production rate is 83%. The concentrated wastewater 11 is discharged or disposed of; the diluted sodium chloride solution After entering the subsequent electrodialysis unit 4 for concentration, the concentrated sodium chloride solution 12 reaching 100 g / L is returned to the forward osmosis unit 3 as a drawing solution, and the obtained pure water 13 is reused at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com