Reverse osmosis type water conditioner able to improve pressure automatically

A technology of reverse osmosis and membrane water purifier, applied in the direction of osmosis/dialysis water/sewage treatment, reverse osmosis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

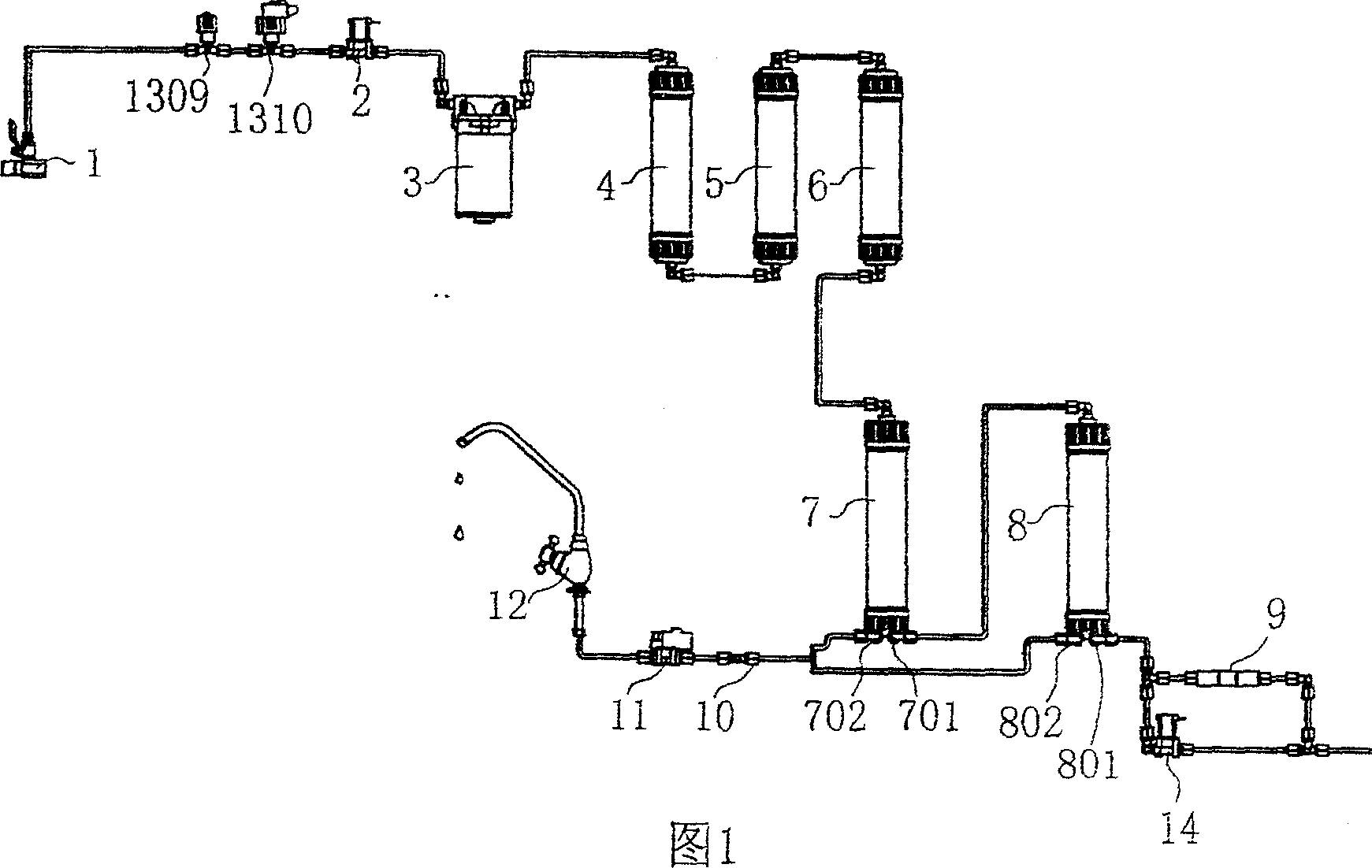

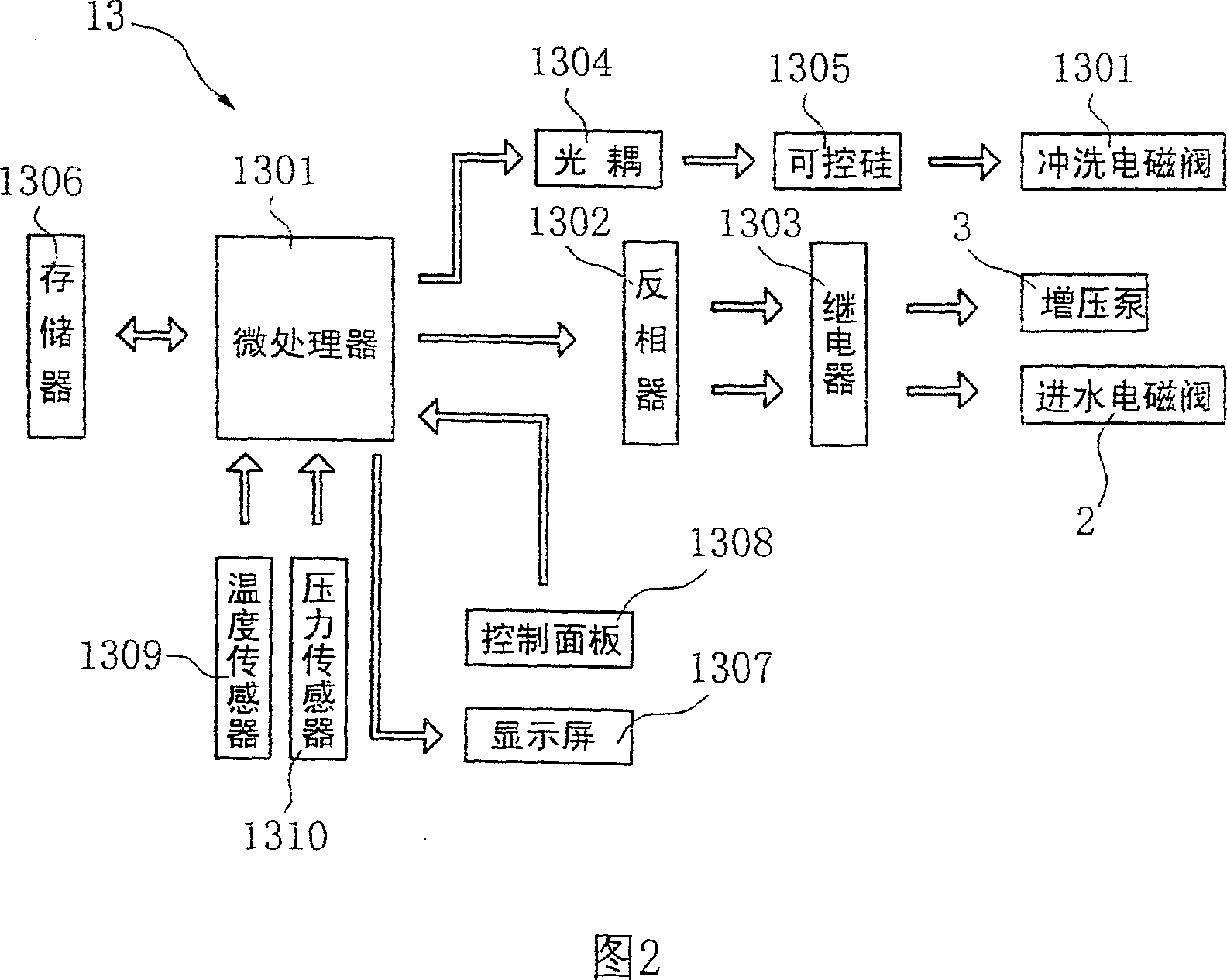

[0016] As shown in Figure 1, a reverse osmosis membrane water purifier capable of automatic pressurization has an organic casing (not shown in the figure), and the raw water is connected to the valve 1 inside and outside the casing, the raw water is connected to the valve 2, and the water inlet solenoid valve 3 , booster pump 4, 5u polypropylene filter element 5, sintered activated carbon filter element 6, 1u polypropylene filter element 7, reverse osmosis membrane elements, connected in sequence, including 5u polypropylene filter element 4, sintered activated carbon filter element 5, 1u The polypropylene filter element 6 has constituted the primary filter device of this water purifier. In addition, the waste water outlet 701 of the reverse osmosis membrane element 7 is connected to a reverse osmosis membrane element 8 in pipelines. Two reverse osmosis membrane elements 7 and 8 can reduce the discharge of waste water, improve the water purification rate of the water purifier, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com